Over the past 30 years, I have watched Lean drift far from its origins. What began as a practical, people centered system inside Toyota was turned into a commercial structure of belts, labels, and certification pathways. One of the major contributors to this shift has been the American Society for Quality (ASQ). Once grounded in the work of Deming, Juran, Crosby, Shewhart, and Wheeler, it gradually evolved into a credential marketing platform that absorbed Lean into the Six Sigma hierarchy.

Today we see titles such as:

• Lean White Belt

• Lean Yellow Belt

• Lean Green Belt

• Lean Black Belt

• Lean Master Black Belt

None of these came from Toyota. They were never part of the Toyota Production System. They were not part of Ohno’s work, Shingo’s teachings, or the learning culture that created TPS. These labels came from Six Sigma and were later pasted onto Lean, creating the illusion that Lean is a competency ladder of belt levels. This is not how TPS was built.

In TPS learning, we were always taught to separate pioneers, architects, and practitioners. Ohno and Shingo were clear that the system is not JIT, not tools, and not a list of steps. TPS is a complete system built on four elements: Jidoka, Just in Time, Kaizen, and respect. Skill came from practice, coaching, and learning by doing, not from short courses or multiple choice exams.

I joined ASQ in 1996. I earned certifications as a CQT, ASQ CQE, CQA, and CSSBB. I also served as chair of ASQ Ottawa Section 407. I believed in the profession. But over time I saw a steady shift away from foundational principles toward increasingly commercial training structures. The goal became selling titles rather than advancing understanding. Quality became a marketplace. Lean became an accessory.

For me, this is not a neutral topic. It became a personal mission.

This is why I created Lean TPS. It is not a brand or a consultancy. It is a reclaiming effort. The purpose is to restore what TPS was built on: respect for people, structured problem solving, stability through Standardized Work, prevention through Jidoka, and capability before credentials. Lean TPS is not a Six Sigma add on. It is the original thinking system that shaped modern manufacturing long before belts existed.

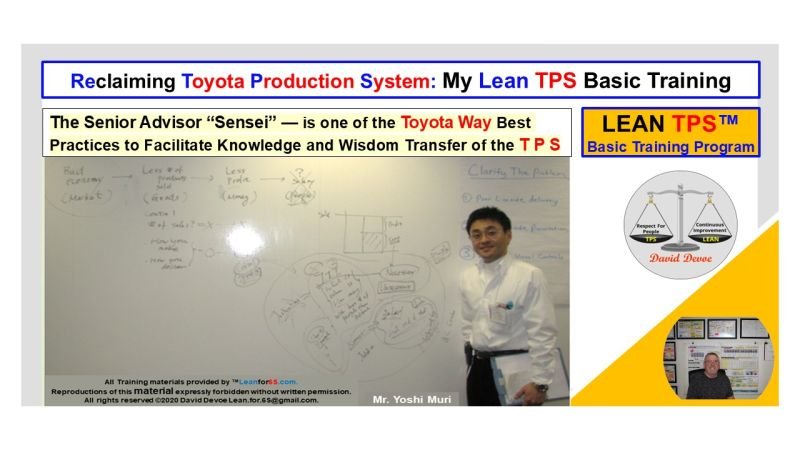

To push this conversation forward, I use the visual below in my basic training program. It asks a simple question: what would Mr. Ohno or Dr. Shingo think about the way Lean is sold today? My suspicion is that they would be highly critical. Both emphasized scientific thinking, real problem identification, and improvement through learning by doing. They did not teach color coded titles or maturity ladder systems. They taught people to understand causes and improve work.

For those interested in the broader history and how TPS was built, I documented the pioneers who shaped the system here:

https://lnkd.in/gzrG6gwg

If you have experience with ASQ’s transformation or have seen similar dilution of TPS principles, I welcome your perspective. The purpose is not criticism for its own sake. It is to reconnect Lean with the foundation that made it effective: people, science, learning, and responsibility.

Please share, comment, and like to help bring Lean back to its roots.

#LeanTPS #LeanTPSSwissCheeseModel #ContinuousImprovement #5SThinking #KaizenThinking #JustInTime #Jidoka #StandardizedWork