Welcome to LeanTPS.ca

Built on Toyota’s principles of Respect for People and Continuous Improvement, LeanTPS.ca shares how structured improvement develops leadership and protects flow.

The Purpose of LeanTPS.ca

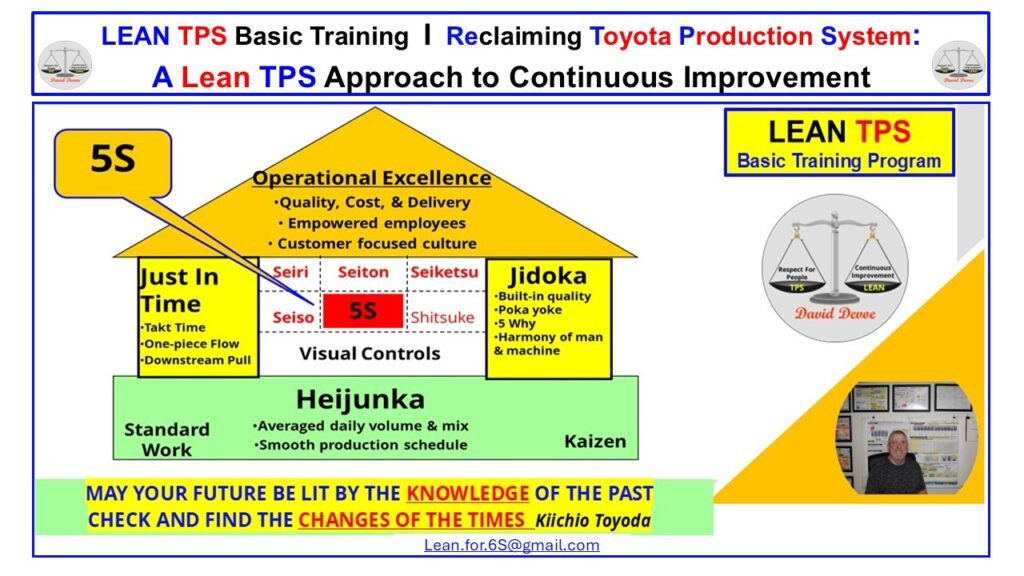

Welcome to LeanTPS.ca. This site exists to share clear and structured knowledge based on the Toyota Production System. Lean TPS is a system for developing people and preventing failure. Improvement does not begin with tools. It begins with education, practice, and the ability to see problems as they occur in the real workplace. TPS requires leaders to support learning and accountability at the Gemba. Each resource on this site is designed to help teams understand cause, effect, and the discipline of Standardized Work.

LeanTPS.ca is also dedicated to reclaiming the original intent of the Toyota Production System. The content shared here comes from real TPS experience. My background includes training at Toyota Industries Corporation in Kariya, study at the Takahama Plant with Toyota Logistics & Forklifts, and years of leading and supporting Jishuken activity across North America. I have worked as a TPS Manager Coordinator, Continuous Improvement Facilitator, and Jishuken working group member within TMHMNA. The material on this site reflects the environments where leaders learn to see problems, solve them at the source, and develop capability in others. The goal is to help organizations understand TPS as a people system that protects flow, strengthens processes, and builds learning at every level.

Reclaiming the Toyota Production System

The Toyota Production System is not a philosophy, framework, or collection of tools. It is a governed production and management system designed to protect Quality, expose abnormalities, and compel leadership response through daily work.

TPS does not function through interpretation. It functions through enforced conditions. When those conditions are present, problems surface early, learning is unavoidable, and leadership accountability is built into the system. When those conditions are removed, TPS no longer governs behavior or outcomes, regardless of the language used to describe it.

Much of what is labeled Lean today draws selectively from TPS while removing its governing mechanisms. TPS is often repositioned as historical influence, philosophical foundation, or source material for Lean (post-1988). In that reframing, Lean becomes the operating construct, while TPS is reduced to reference content rather than a system that must be actively operated and verified.

This reordering has consequences. When TPS conditions are optional, Quality becomes conditional. Abnormalities are managed through explanation rather than exposed through design. Leadership accountability shifts from obligation to discretion. Failure does not arrive suddenly. It accumulates quietly behind stable language, professional legitimacy, and well-structured frameworks that no longer constrain work.

LeanTPS.ca exists to maintain a clear boundary.

If the Toyota Production System is being cited, it must be engaged as a governed production and management system. If those governing conditions are absent, then TPS is not in use and should not be referenced as such. Lean (post-1988) may continue to evolve as a collection of methods and practices, but that evolution does not grant it authority over TPS, nor does it allow TPS to be reclassified into something it was never designed to be.

This site documents TPS as it is practiced, taught, and verified in real environments. The focus is not adoption, alignment, or interpretation. The focus is operation. Where TPS governs, Quality is protected, learning is forced, and leadership is accountable. Where it does not, systems drift and failure becomes predictable.

That boundary is non-negotiable.

Updates from the Lean TPS™ network plus real case studies and leadership papers.

Each white paper connects Toyota principles to daily practice with structure and purpose.

I’m David Devoe, a Lean TPS Continuous Improvement Facilitator with more than ten years working at Toyota. That experience was at Toyota BT Raymond in Canada, where I developed my TPS foundation through direct application in a North American manufacturing environment. I was the TPS Manager, responsible for teaching, training, and governing the application of the Toyota Production System.

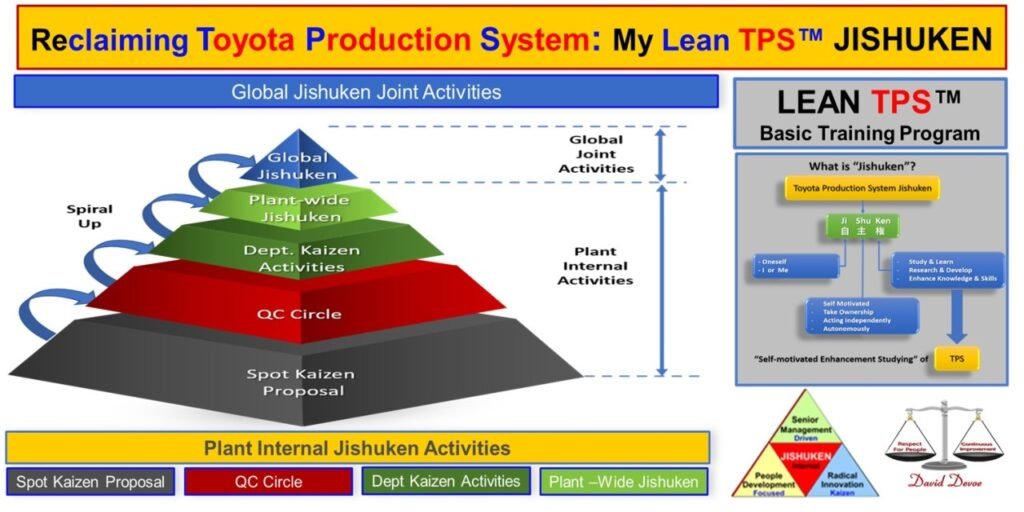

In that role, I led the development and delivery of TPS training and practice so that Japanese system intent was correctly understood and sustained within a Canadian operating and leadership culture. This included hands-on deployment, leadership coaching, and the execution of Jishuken activity, ensuring that Quality, stop logic, and management accountability were not diluted as TPS was applied outside Japan.

I was also a core member of the Toyota Material Handling Manufacturing North America (TMHMNA) TPS working group, where I led and supported Jishuken activity across North America. That work deepened my understanding of the difference between TPS as a governed operating system and Lean as a collection of methods, particularly in how Quality protection and leadership obligation are either enforced or allowed to erode.

My TPS development includes direct training through Toyota Industries Corporation (TICO) in Kariya, Japan, and Kaizen training at the Takahama Plant with Toyota Logistics & Forklifts. That combination of Japanese training and North American responsibility shaped how I understand system governance, leadership accountability, and Quality protection in daily work.

This site is the home for my work on Toyota Production System leadership, Jishuken capability development, and the governed application of Standardized Work, Kaizen, and 5S Thinking. The articles, white papers, and training material published here are drawn from real Gemba experience and are written to help organizations protect Quality, strengthen leadership accountability, and design systems that prevent failure rather than explain it after the fact.

Featured Lean TPS Pages

Core Lean TPS topics: 5S Thinking, the Swiss Cheese Model, and Jishuken.

Each page connects Toyota principles to real Gemba learning and structured improvement.

5S Thinking is the discipline that builds flow, stability, and trust. It begins with sorting and organizing the workplace, but its real purpose is to create a learning environment where structure supports people. Every improvement starts here.

Explains how system weaknesses align to create risk. By strengthening prevention layers in process, leadership, and people, errors are stopped before they occur.

Leadership development through hands-on study and structured improvement at the Gemba. Builds capability by learning through real problem solving.

Lean TPS Newsletter & White Papers

Read the latest Lean TPS™ white papers and case studies that connect Toyota principles to structured improvement and leadership practice.

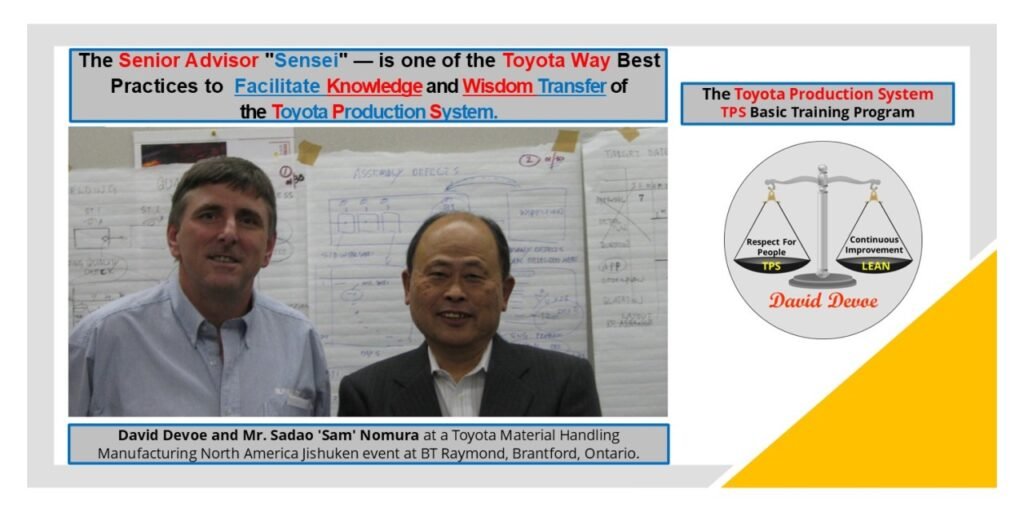

In the world of Lean and the Toyota Production System (TPS), the role of a Sensei is both profound and vital. These master advisors are the custodians of one of the most cherished elements of the Toyota Way, the transfer of knowledge and wisdom that is deeply embedded in TPS philosophy.

Introduction to the Lean TPS Assessment

The Lean TPS Assessment is designed as a practical tool to help organizations measure their progress in applying Lean and Toyota Production System philosophies, practices, and methods. It is not a simple scorecard. It is a structured way to reveal strengths, expose weaknesses, and create a shared language for improvement.

Introduction

My story with the Toyota Production System (TPS) began at Raymond Industrial Equipment (RIE) in Brantford, Ontario. The experiences I gained there, and later through direct involvement in Toyota-led Jishuken activities across North America, shaped how I came to understand continuous improvement, leadership accountability, and the discipline of TPS.

2025 Newsletters

Updates from the Lean TPS network and insights from recent white papers

Core Lean TPS topics: 5S Thinking, the Swiss Cheese Model, and Jishuken.

Each page connects Toyota principles to real Gemba learning and structured improvement.

Reclaiming Toyota Production System: My Lean TPS 5S Thinking

A System-Level Examination of How Governance Is Replaced by Frameworks

Operational Excellence through Lean TPS™ Jishuken

Lean TPS Consulting and Support

Work With David Devoe

Lean TPS Continuous Improvement Facilitator

I help organizations design Lean TPS systems that connect leadership, structure, and daily improvement.

Whether onsite or remote, my focus is to build capability, not dependency, so teams can sustain their own success.

What LeanTPS.ca Provides

LeanTPS.ca provides practical knowledge for organizations that want to understand and apply the Toyota Production System. The focus is on clear explanations of Lean TPS principles, leadership behaviors, and daily work systems that protect flow and prevent failure. This site brings together real experience from Toyota training, Jishuken activity, and continuous improvement work across North America. It is designed to help leaders see problems in their processes, understand why they occur, and build the capability to solve them at the source. The purpose of LeanTPS.ca is to support organizations that want to strengthen their operations through Standardized Work, Gemba leadership, and structured problem solving.

Articles & White Papers • 5S Thinking • Lean TPS Swiss Cheese Model • Jishuken • Contact

Lean TPS Continuous Improvement Facilitator | Ottawa, Canada | LeanTPS.ca | Lean.for.6S@gmail.com