Lean TPS 5S Thinking Series

Lean TPS 5S Thinking Series explains how 5S creates structure, discipline, and visibility for improvement. Each article connects 5S to Kaizen, Jishuken, and Standardized Work to show how improvement becomes daily behavior.

My Lean TPS 5S Thinking: The Foundation for Sustainable Improvement

My Lean TPS 5S Thinking builds the foundation for sustainable improvement by integrating structure, discipline, and respect for people into daily operations.

Lean TPS Starts with 5S Thinking: Structure Before Flow

Lean TPS begins with 5S Thinking. It is not cleaning. It is structure. It creates the visibility and control that make improvement possible.

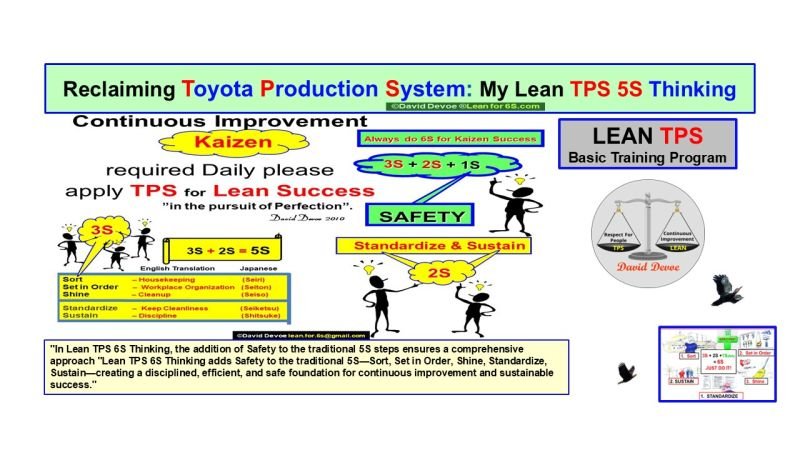

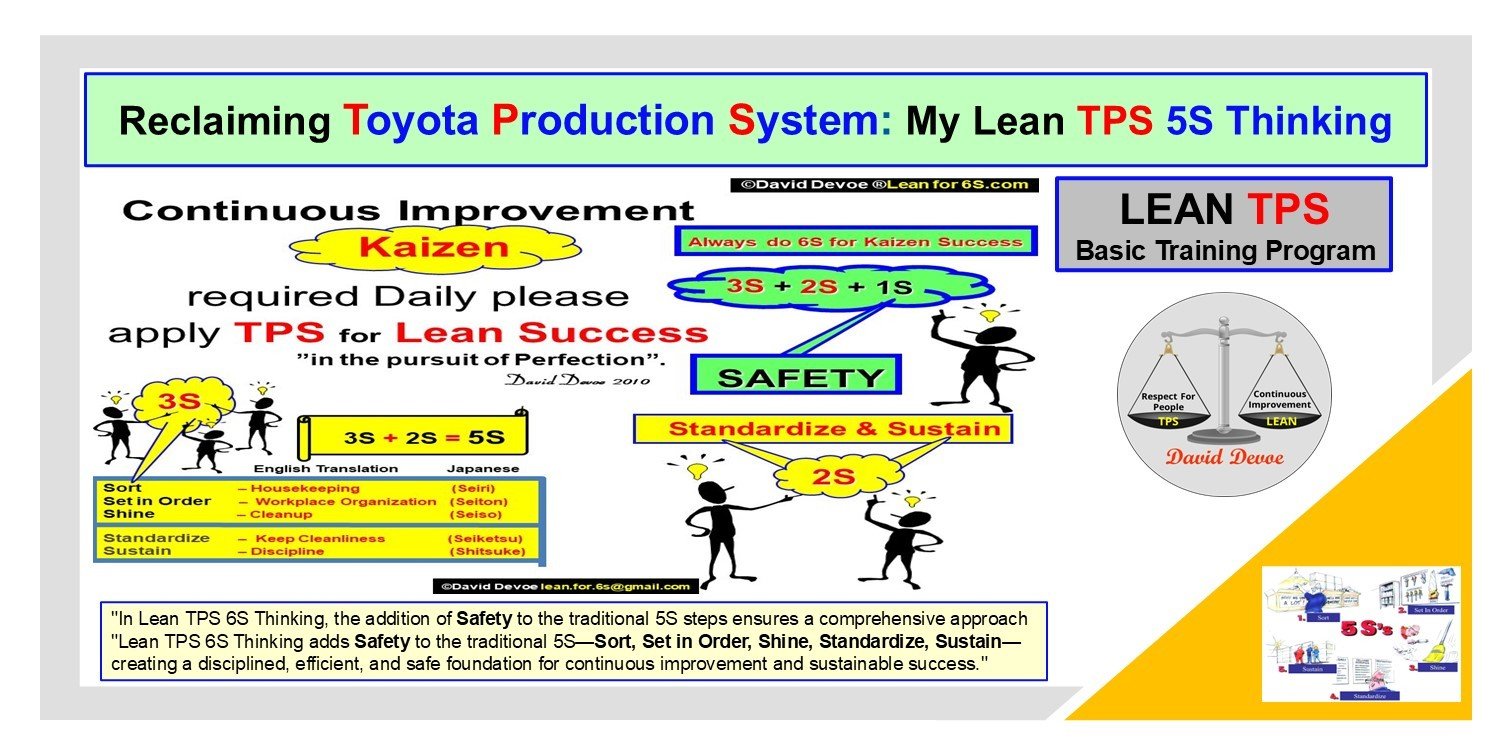

Building a Safer 5S Foundation: My Lean TPS 6S Thinking

Lean TPS 6S Thinking strengthens the traditional 5S system by integrating Safety into every step. The result is a workplace that is efficient, organized, and built on respect for people.

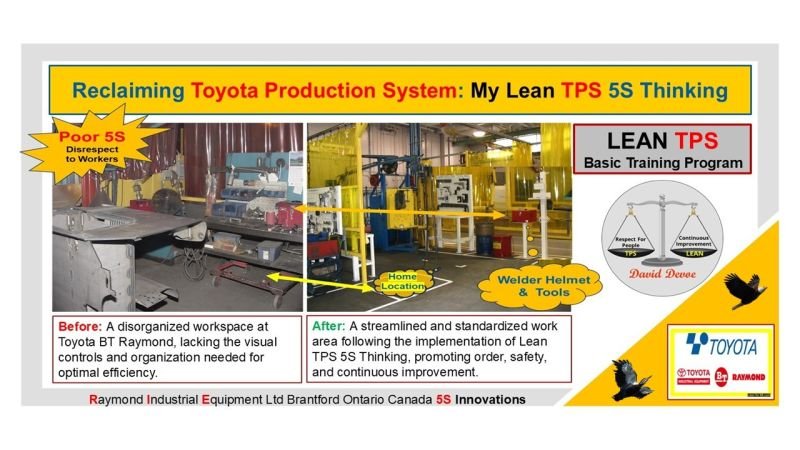

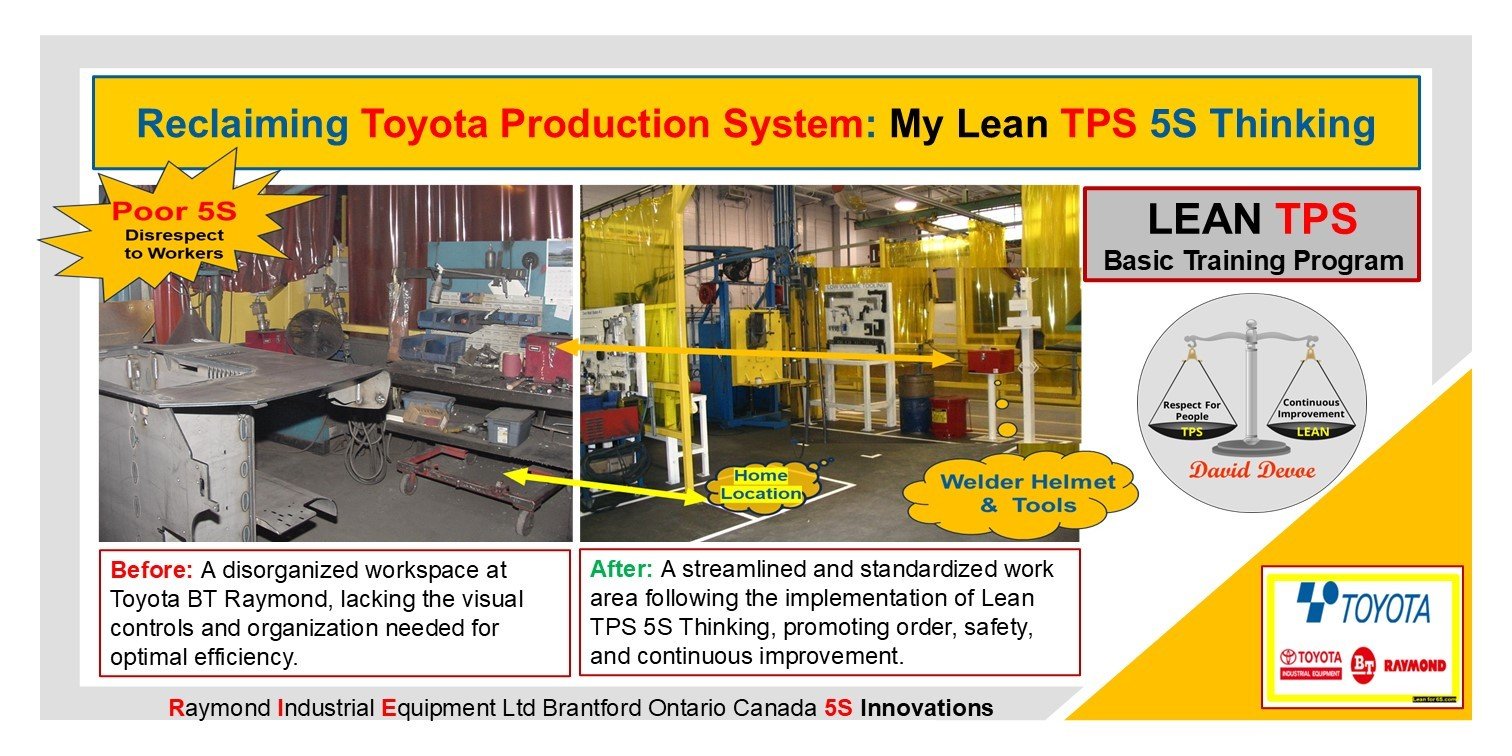

5S Thinking in Action: Restoring Respect and Efficiency

At Toyota BT Raymond, 5S Thinking transformed a disorganized workspace into a model of order and safety. Standardization, visual control, and respect for people built the foundation for sustained improvement.

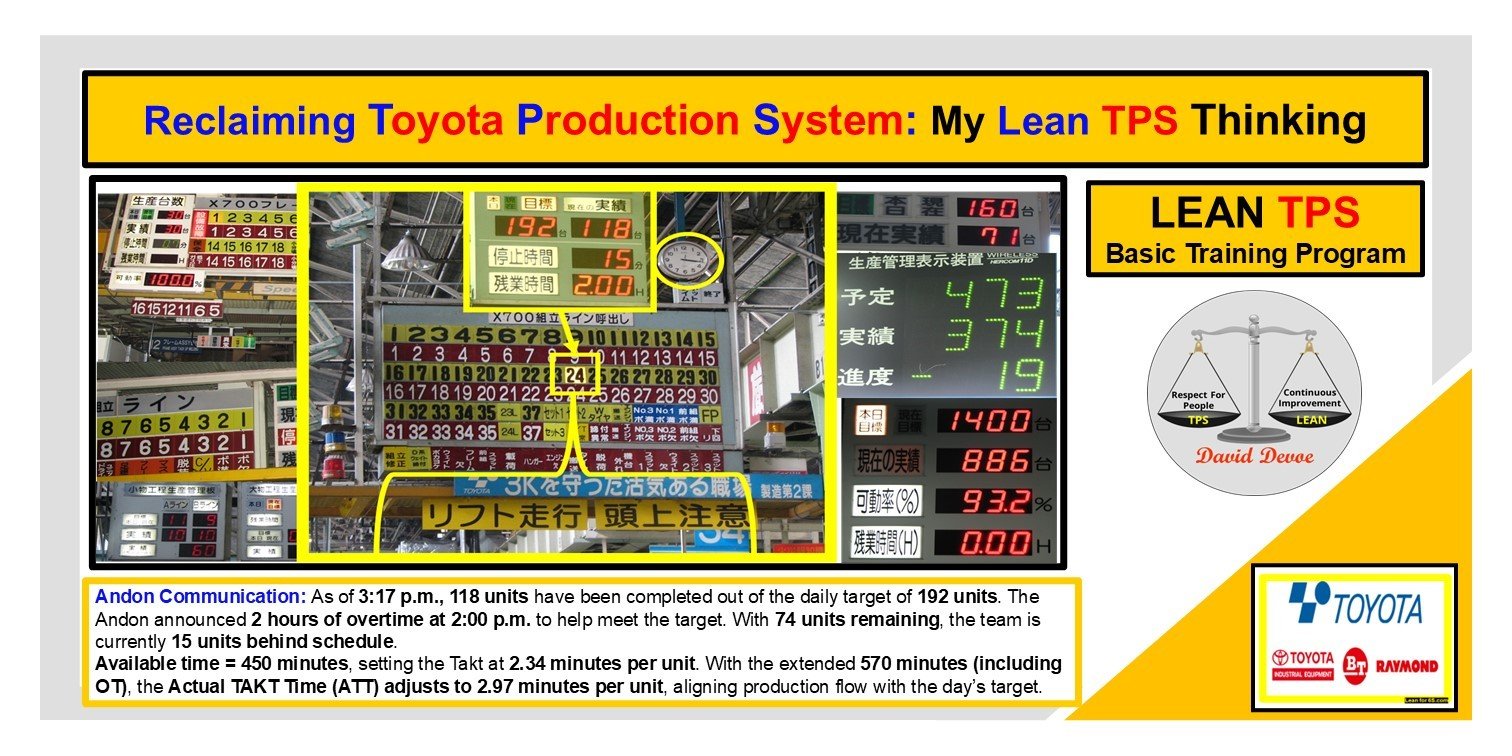

Real-Time Visual Management: Standardizing and Sustaining 5S Thinking

Lean TPS uses visual management to sustain improvement. Andon systems connect Standardize and Sustain, creating visibility and accountability that drive long-term 5S performance.

How Lean TPS 5S Thinking Builds a Continuous Improvement Culture

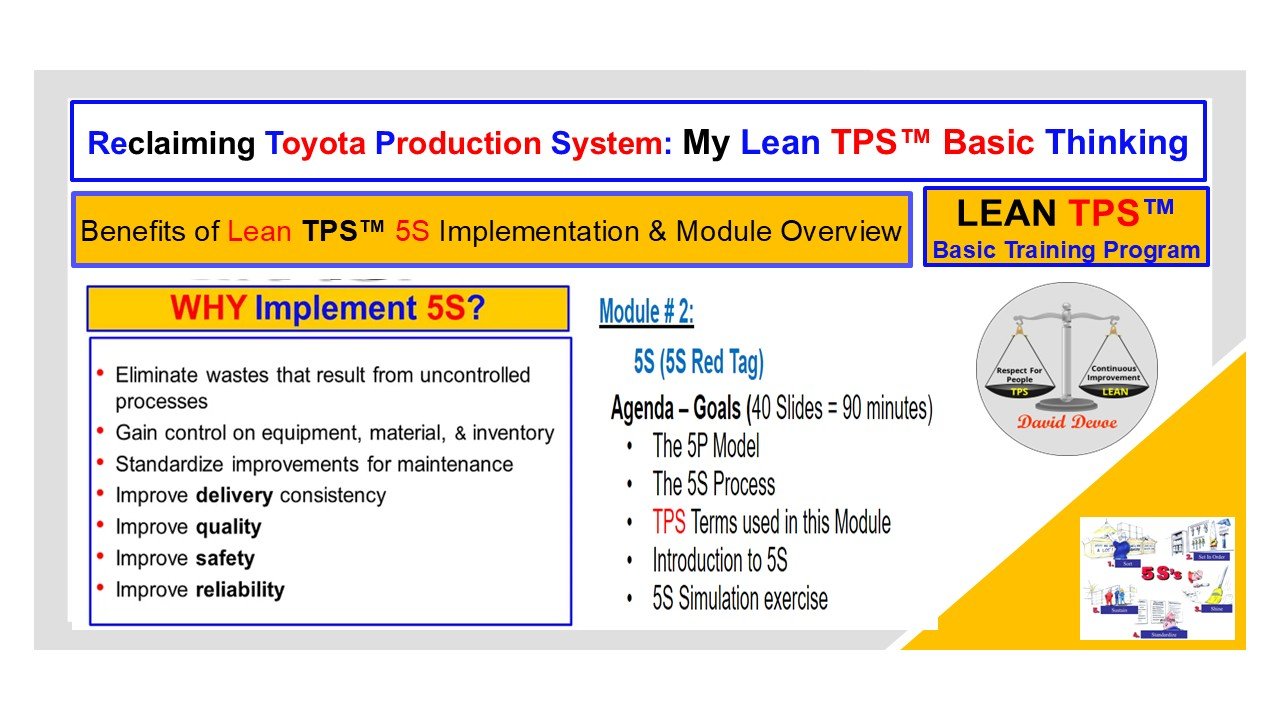

Lean TPS 5S Implementation overview showing training benefits, module structure, and key learning topics used in Lean TPS Basic Training.

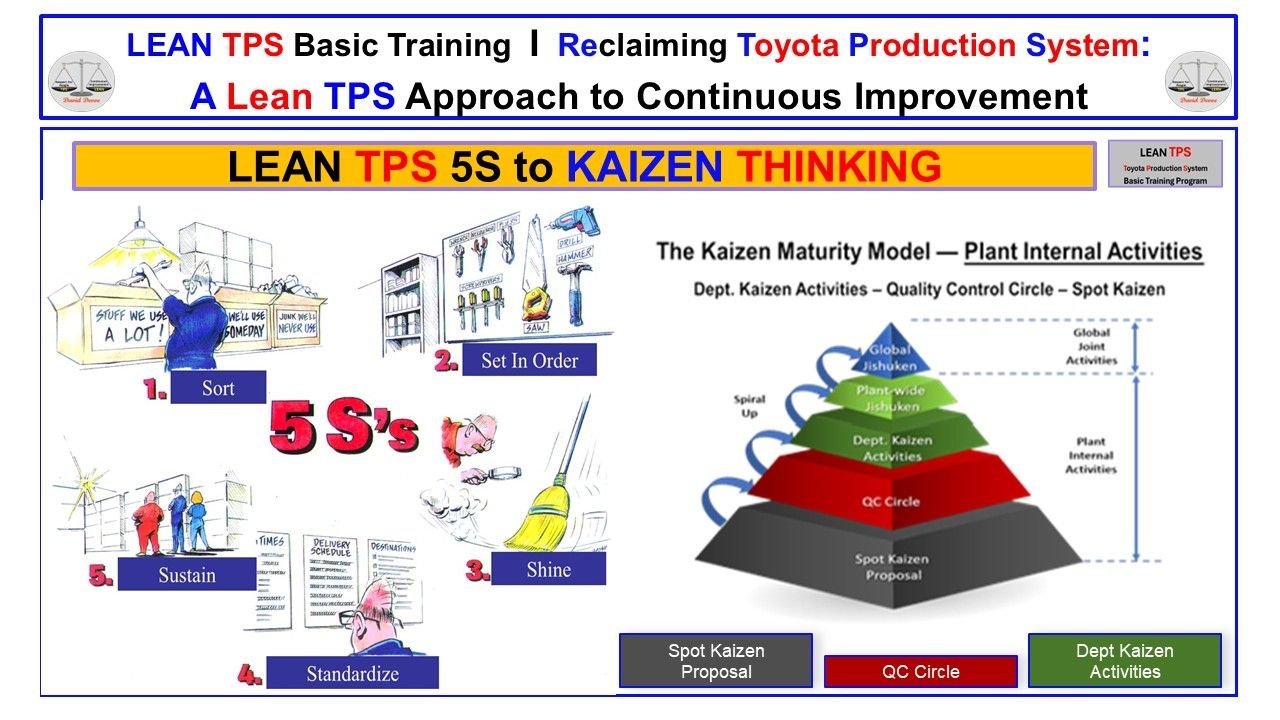

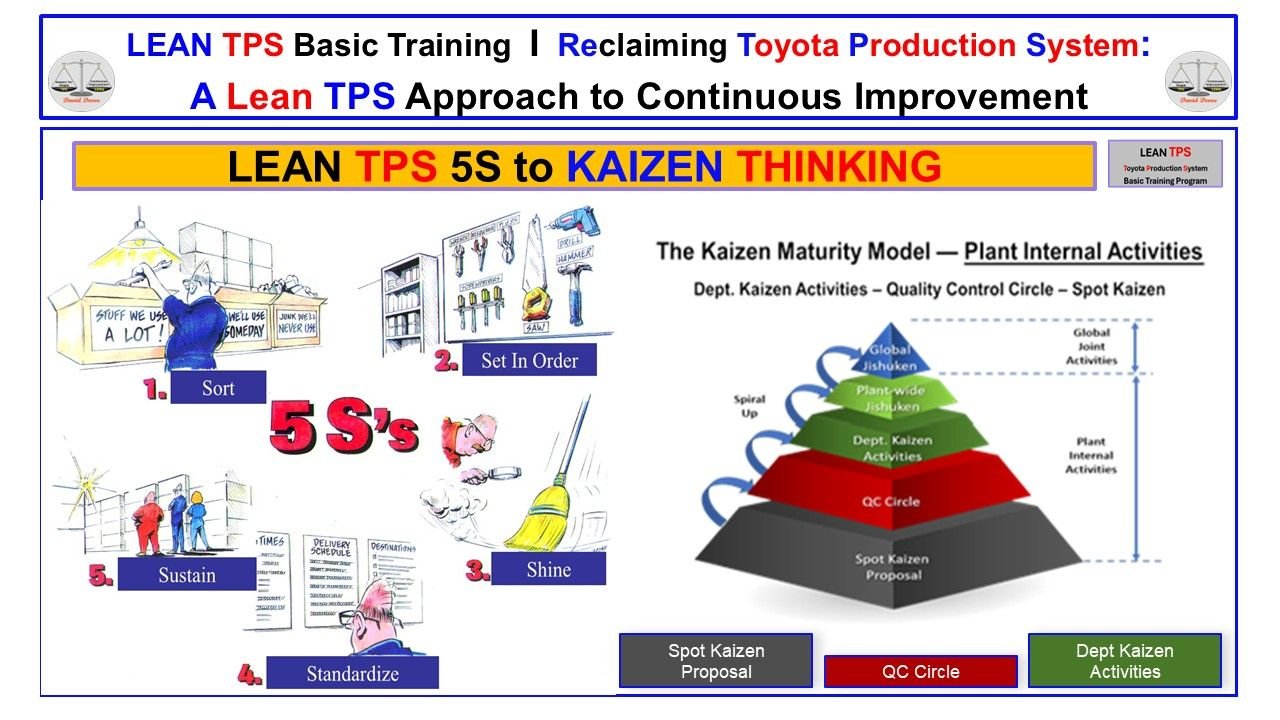

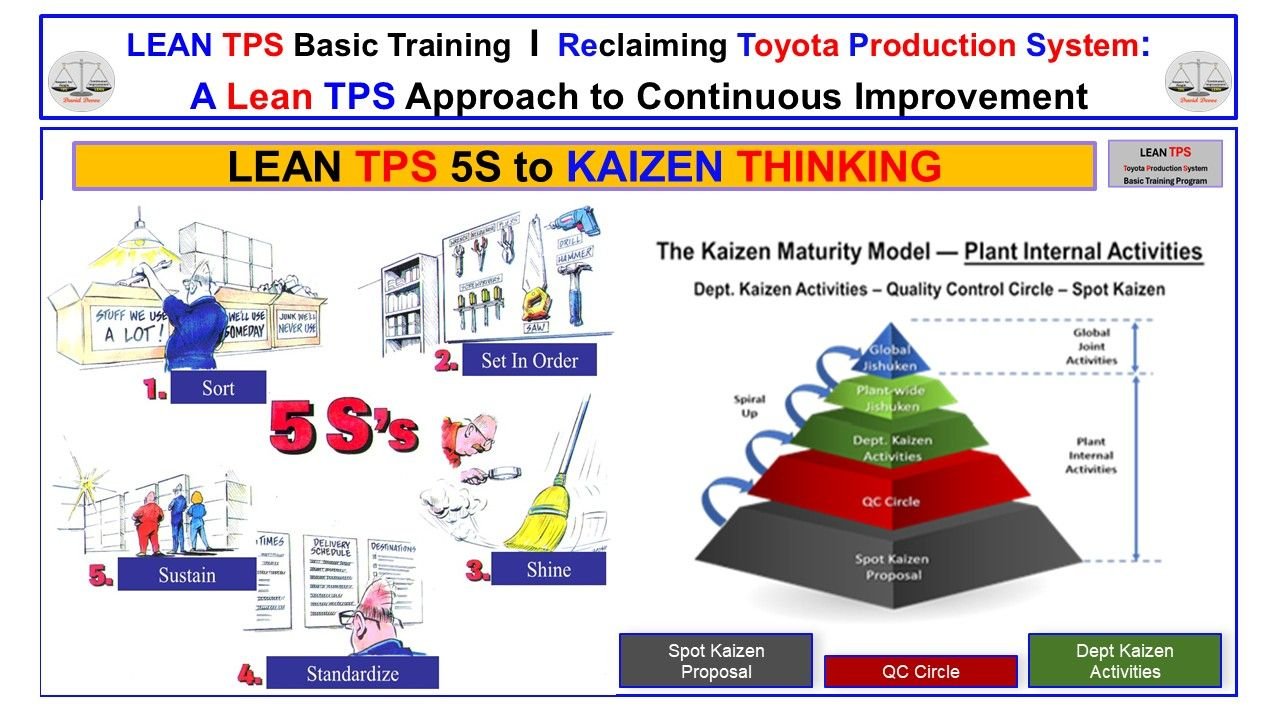

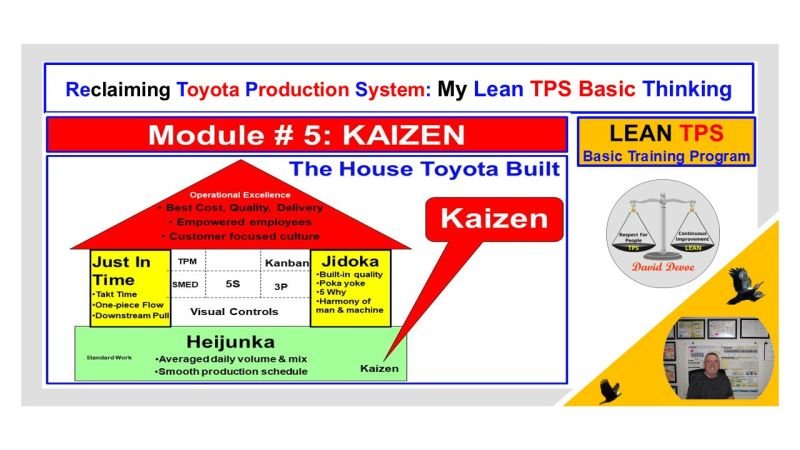

Lean TPS 5S to Kaizen Thinking

Lean TPS 5S Thinking is not about organization. It is about building the structure that makes Kaizen Thinking and leadership learning possible.

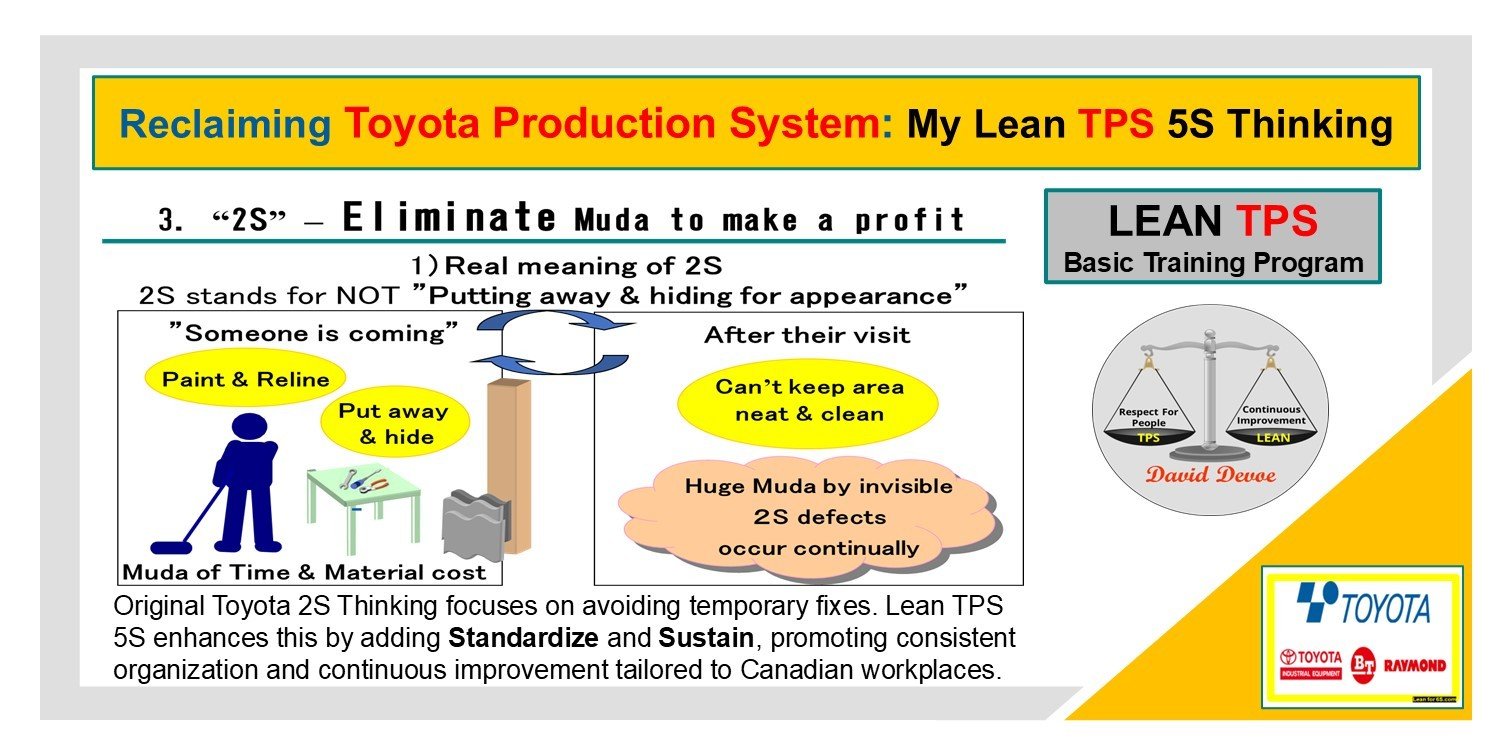

2S – Eliminate Muda to Make a Profit: The Real Meaning of Lean TPS 2S Thinking

Toyota’s 2S Thinking, the foundation of 5S, teaches that true improvement begins by exposing waste, not hiding it. By focusing on Sort and Set in Order, Lean TPS 2S Thinking eliminates Muda and creates the discipline needed for lasting results. Real improvement is structure, not appearance.

My Lean TPS 5S Leadership Training

5S Thinking in Lean TPS is a leadership-driven system that stabilizes operations, eliminates waste, and sustains continuous improvement.

Kaizen TPS for Lean Success: Linking Toyota’s 5S Thinking to Ford’s CANDO System

Toyota’s 5S Thinking originated from Ford’s CANDO system of Clean, Arrange, Neatness, Discipline, and Ongoing improvement. By adapting these principles into 5S and later adding Safety, Toyota created a complete system for structure, discipline, and respect. Lean TPS 6S Thinking connects efficiency with human care, making continuous improvement sustainable.

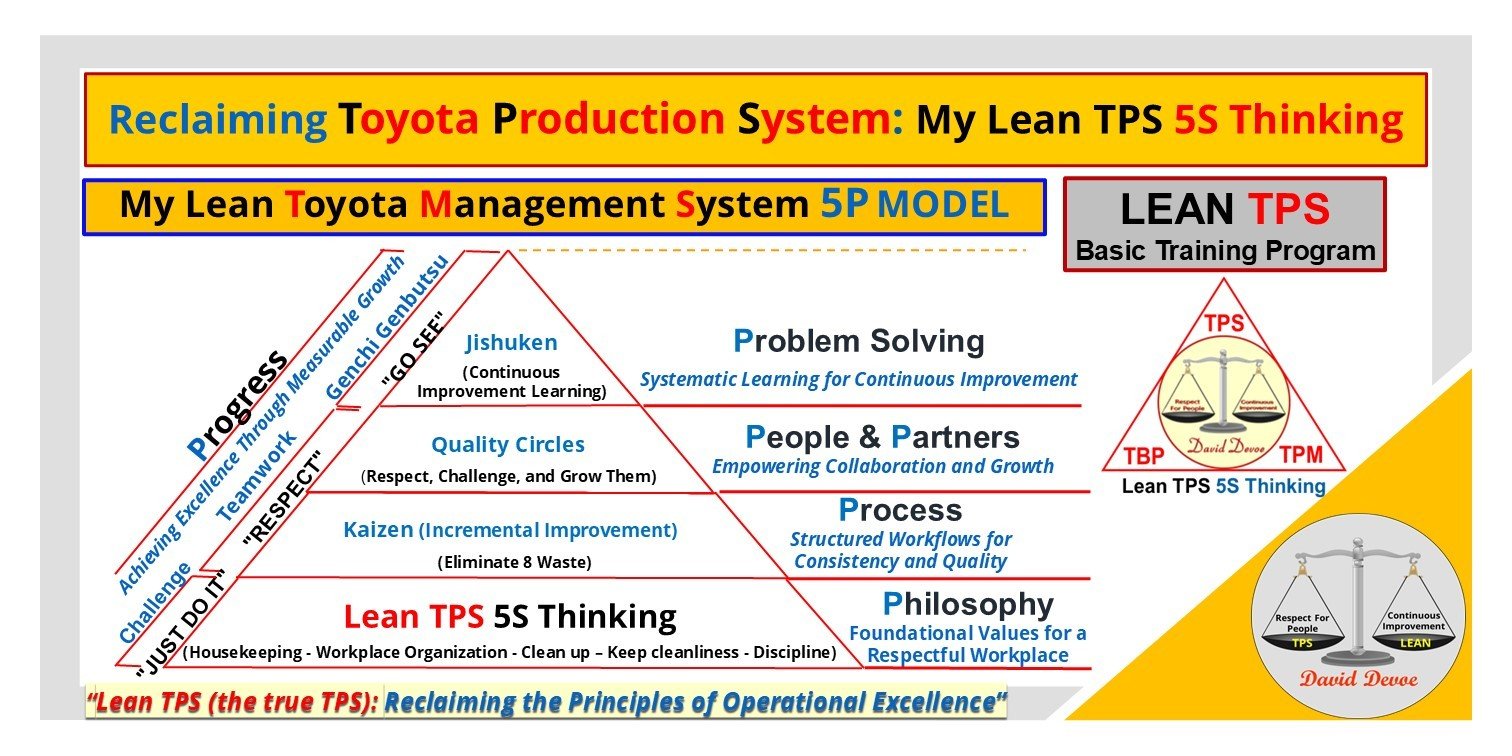

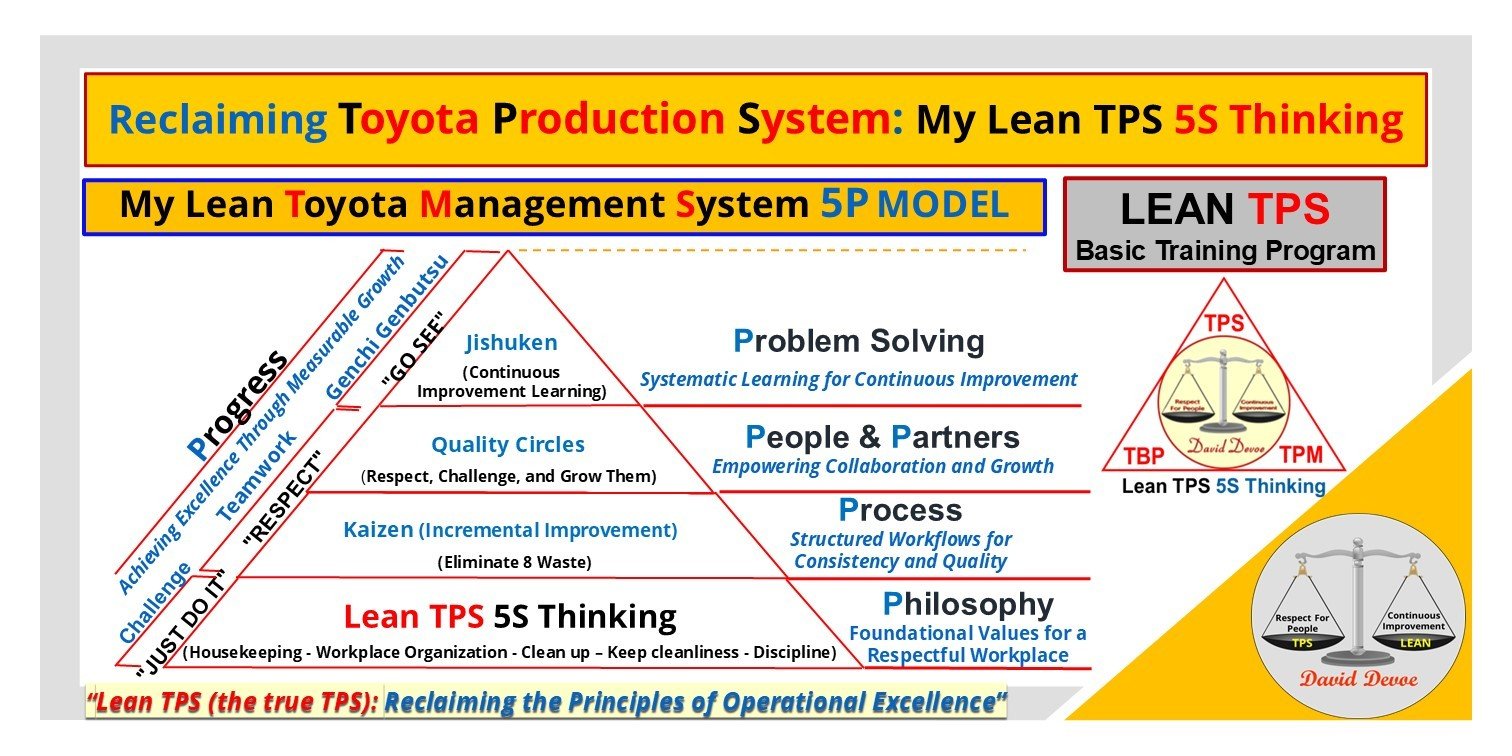

Building Operational Excellence through My Lean TPS 5S Thinking

My Lean TPS 5S Thinking builds the foundation for operational excellence. It integrates 5S discipline with Kaizen, Jishuken, and the Toyota Way 4P Model to create structure, safety, and learning. When 5S becomes a habit, it reveals waste, stabilizes flow, and turns continuous improvement into a daily practice of respect.

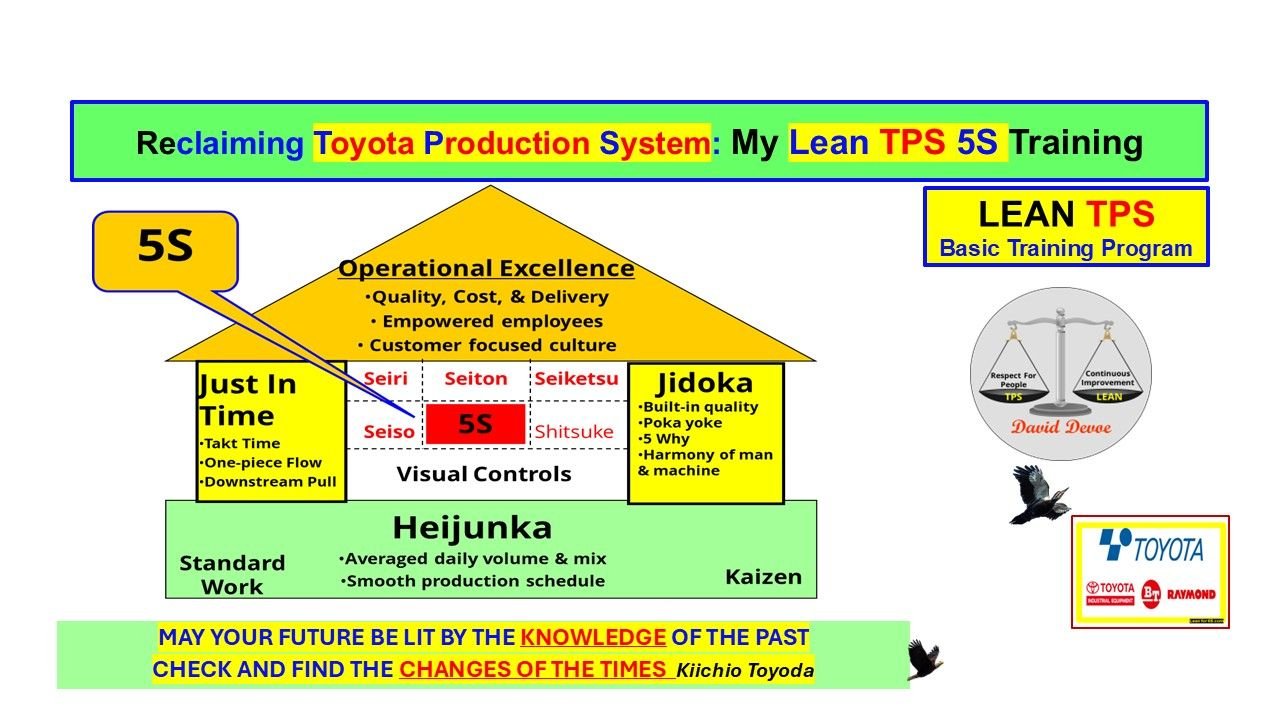

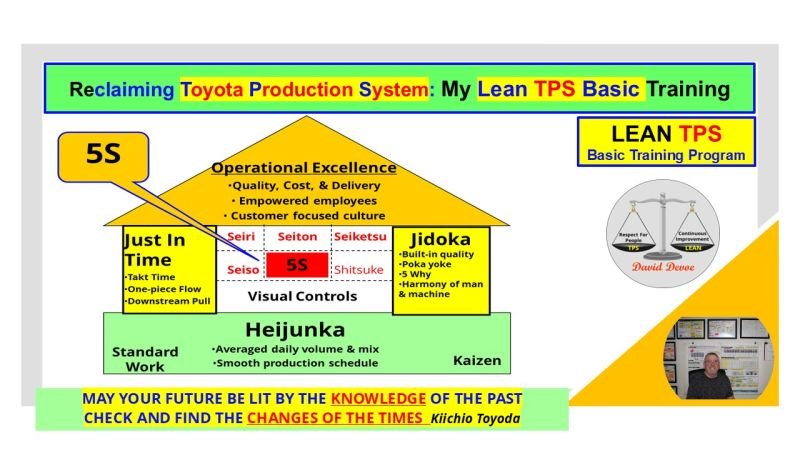

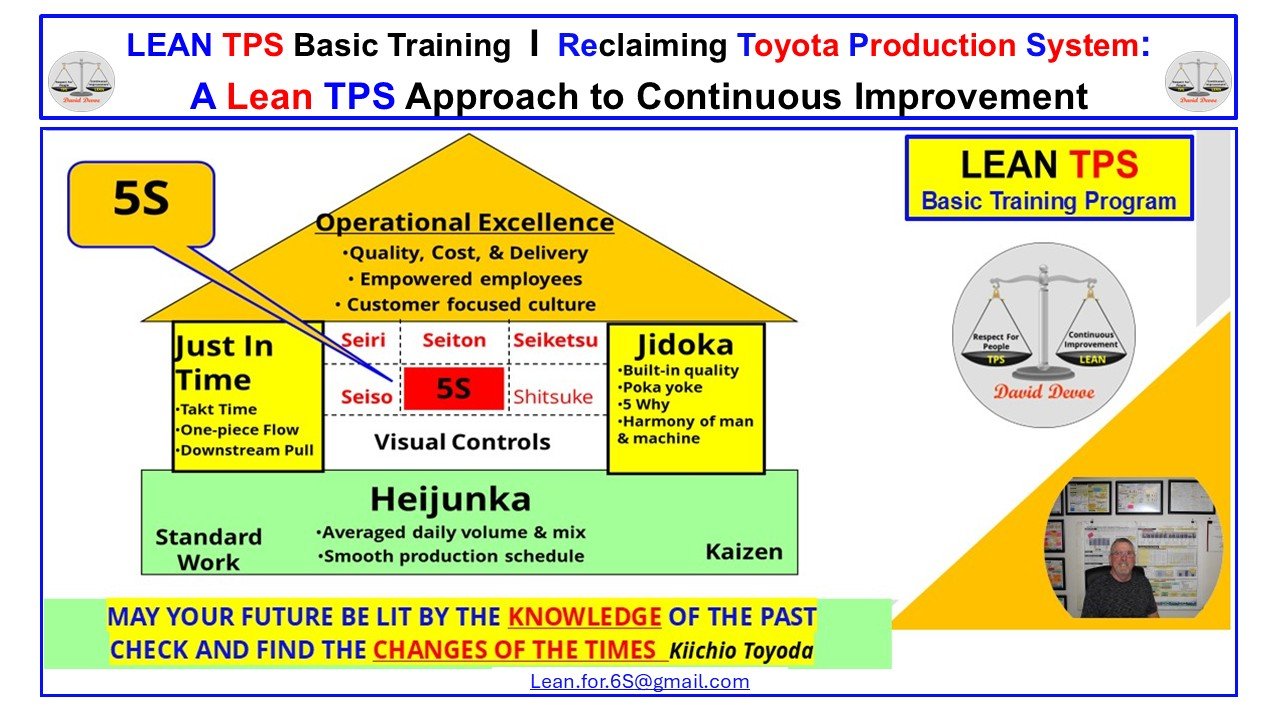

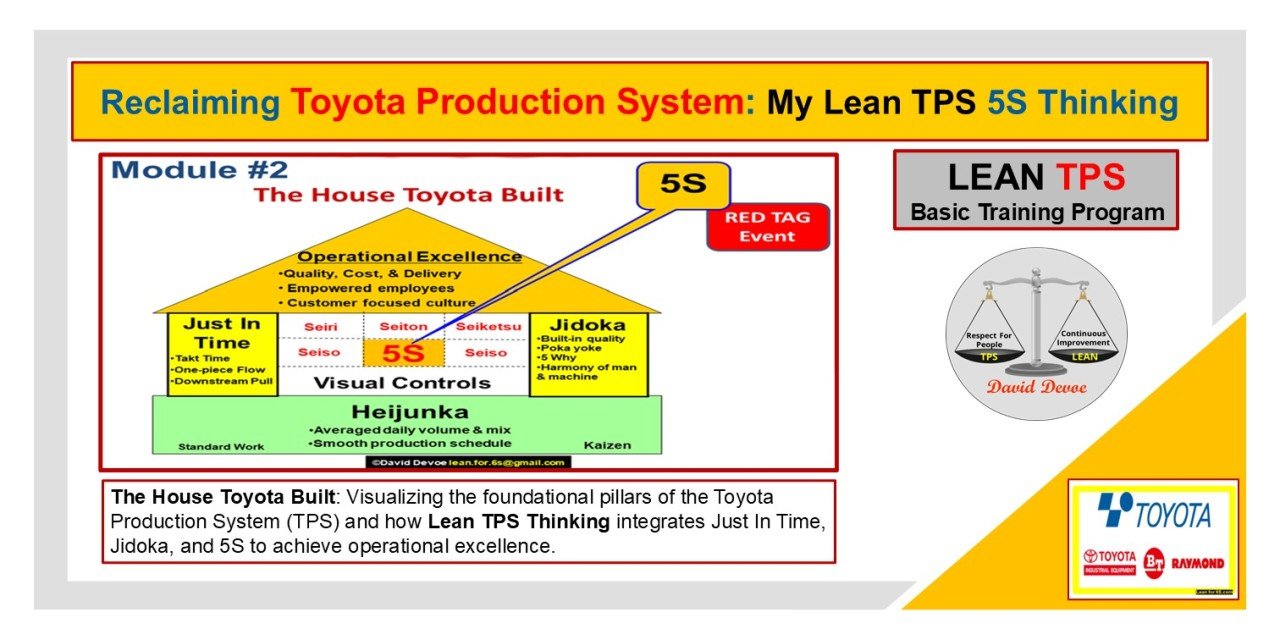

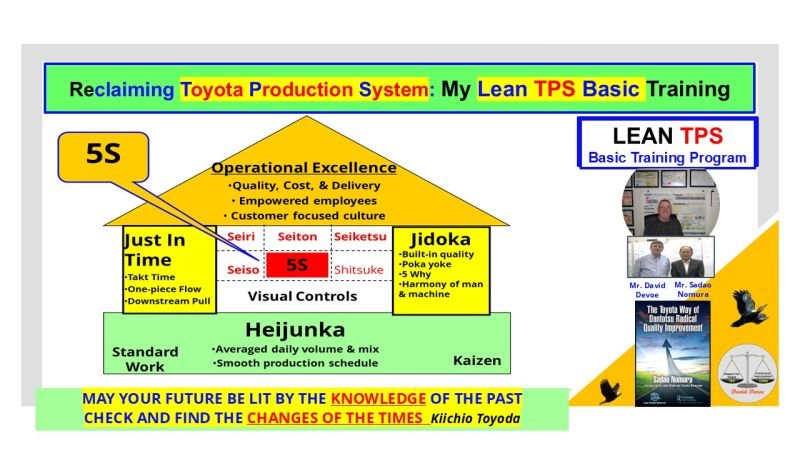

The House Toyota Built: Visualizing the Foundation of Lean TPS 5S Thinking

The foundation of the Toyota Production System is built on 5S Thinking, Standardized Work, Heijunka, and Kaizen. 5S is not housekeeping. It is the structure that enables flow, quality, and improvement. When 5S becomes daily practice, the entire Lean TPS system grows from it naturally.

Lean TPS 5S Thinking: The Foundation for Continuous Improvement

In Lean TPS, 5S Thinking is not about cleaning. It is the foundation for structure, visibility, and leadership engagement that make continuous improvement possible.

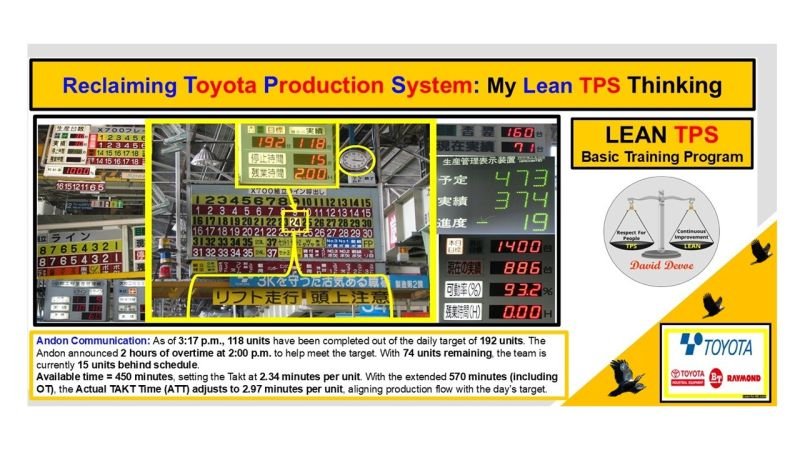

Andon Communication Board: Real-Time Metrics for Efficient Workflow Adjustments

The Andon communication board shows Lean TPS in action. By making production data visible, teams at Toyota BT Raymond align workflow with Takt time, respond to problems instantly, and maintain stability. Real-time visibility turns data into action, reinforcing teamwork, learning, and continuous improvement on the shop floor.

Transformation Through My Lean TPS 5S Thinking: The Weld Cell Before and After

At Toyota BT Raymond, Lean TPS 5S Thinking transformed a cluttered weld cell into a safe, efficient, and organized workspace. By applying the five steps of 5S, the team eliminated waste, standardized flow, and built a culture of respect where operators could focus on quality and continuous improvement.

The Lean TPS 5P Model: A Structured Approach to Excellence

The Lean TPS 5P Model links purpose, process, people, performance, and perfection into a single framework for improvement. Paired with The Toyota Way 4P Model, it aligns actions with long-term philosophy and daily discipline. Together they form a complete system for leadership, learning, and sustainable operational excellence.

How We Really Learn: Why 5S Is the First Step in Lean TPS Training

Training is often misunderstood. Many organizations believe it happens in classrooms through lectures, slides, and awareness campaigns. But real learning comes through participation. We learn

Lean TPS 5S Thinking: The Foundation for Sustainable Improvement

5S Thinking is the disciplined foundation of Toyota’s Lean TPS. It transforms organization into waste elimination and develops the structure for sustainable improvement.

The House Toyota Built: 5S Thinking as the Foundation for Kaizen

5S Thinking provides the foundation for Kaizen at Toyota. When applied as a system of thinking, it evolves into 2S, where continuous improvement becomes daily habit.

Lean TPS Support and Capability Development

Lean TPS support is available for plant teams, regional operations, and leadership development. Support includes structured improvement, capability building, and systems-based problem solving grounded in Toyota methods.

Services include:

• Continuous Improvement Facilitation

Structured guidance to stabilize flow, expose abnormalities, and strengthen daily management through Standardized Work.

• Jishuken Leadership Development

Hands-on improvement cycles that build leadership capability through participation, observation, and accountability.

• Lean TPS 5S Thinking and Workplace Organization

Establishing structure, visual control, and discipline to protect flow and prepare teams for Kaizen.

• Standardized Work Design and Audit Support

Developing the best-known method, connecting people to process, and sustaining improvement through leader observation.

• Jidoka and Abnormality Management

Making problems visible through Stop–Call–Wait, quality response routines, and structured root cause analysis.

• Kaizen Facilitation

Practical improvement activities that eliminate waste, reduce variation, and support continuous flow.