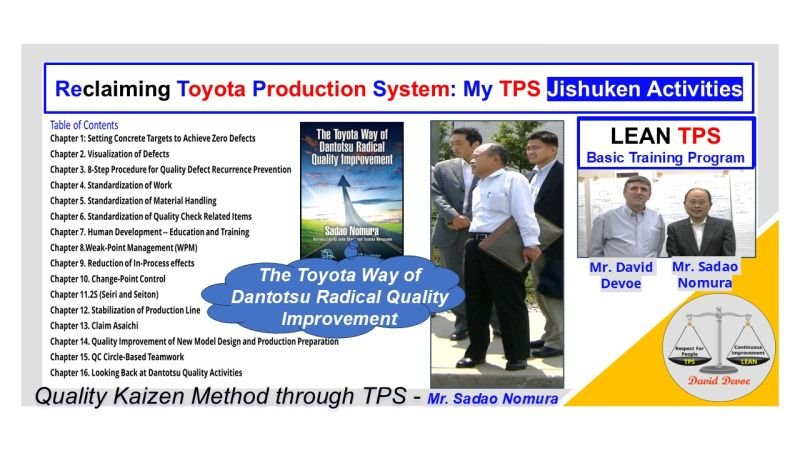

A Legacy of Lean TPS Kaizen and Jishuken Leadership Development

The Dantotsu Quality Method, developed by Mr. Sadao Nomura, represents Toyota’s highest level of continuous improvement and quality leadership. Dantotsu means “better than the best.” It is the result of structured Kaizen, disciplined leadership, and the mindset of never accepting defects.

Mr. Nomura’s Dantotsu activities redefined quality across Toyota’s global operations. His approach focused not only on process improvement but also on developing people through Jishuken, Toyota’s method of self-motivated study and structured leadership development.

The Foundation of Dantotsu Quality

Mr. Nomura joined Toyota in 1965 and spent his career improving quality and manufacturing capability. During his time at the Motomachi Plant, he led transformation efforts that stabilized production and eliminated chronic quality problems during the launch of the sixth-generation Mark II (Cressida).

Between 2006 and 2014, as a senior advisor for Toyota Logistics and Forklift (TL&F), he guided global Dantotsu initiatives that reduced defects, improved flow, and strengthened leadership capability. His method combined TPS fundamentals Jidoka, Just-in-Time, and Kaizen with the disciplined use of PDCA to sustain long-term improvement.

Nomura’s principle was clear: Quality must be built in at every step, not inspected in later.

My Experience Working with Mr. Nomura

As the TPS representative for the Canadian facility within Toyota Material Handling Manufacturing North America (TMHMNA), I worked directly with Mr. Nomura from 2006 to 2009. During this time, we implemented Jishuken-based quality improvement activities that applied his Dantotsu thinking to every process.

Nomura’s coaching style was grounded in Genchi Genbutsu go and see for yourself. His handwritten A3 sheets, known as “Nomura-Grams,” visualized problems, clarified thinking, and guided action. Every improvement cycle connected leadership development with process stability.

The Dantotsu Quality Results

Under Nomura’s guidance, TMHMNA achieved measurable results that demonstrated the power of TPS when practiced with discipline and respect for people.

- Defects reduced by 98 percent across global sites.

- Productivity increased by 450 percent in one facility before automation was introduced.

- Warranty claims reduced by two-thirds through prevention at the source.

- More than 100,000 Kaizen suggestions implemented by associates.

These achievements were not isolated events. They were the result of leadership engagement, structured Jishuken activities, and a culture that encouraged everyone to contribute to improvement.

The Dantotsu Method in Practice

Nomura’s Quality Kaizen method followed a consistent framework that connected daily management with leadership development:

- Build Quality at the Source: Detect and prevent defects during production.

- Visualize Problems: Use Mieruka and Standardized Work to make abnormalities visible.

- Engage in Jishuken: Learn through action and develop leaders through study and reflection.

- Apply PDCA: Structure improvement to ensure learning is captured and sustained.

- Develop People: Cultivate leaders who teach, coach, and model continuous improvement.

The Dantotsu method connected technical systems with human development. It proved that true TPS maturity comes from building capability, not just improving metrics.

Continuing the Legacy

The lessons learned from Mr. Nomura continue to shape my approach to Lean TPS Basic Training, Jishuken leadership development, and structured Kaizen improvement.

Dantotsu Quality represents more than defect reduction. It represents a mindset a pursuit of excellence that drives improvement, develops people, and strengthens culture.

Toyota’s Dantotsu method demonstrates that quality and leadership development cannot be separated. When improvement is driven by respect for people and continuous learning, the result is sustainable excellence.