The Kaizen A3 shows how daily improvement becomes part of the culture. It captures how Toyota turns small, consistent actions into lasting progress. Kaizen is not a project or a workshop. It is a way of thinking that engages everyone in solving problems and improving the work. The Kaizen A3 format makes this thinking visible. It shows how people learn to see, analyze, and act at the root cause.

The A3 begins with a clear purpose. Kaizen is improvement through participation. It combines technical problem solving with human development. The form outlines the steps, principles, and results so that the learning is easy to follow. It shows that the goal of Kaizen is not to fix isolated issues but to build capability in people. When practiced daily, this process strengthens the organization one improvement at a time.

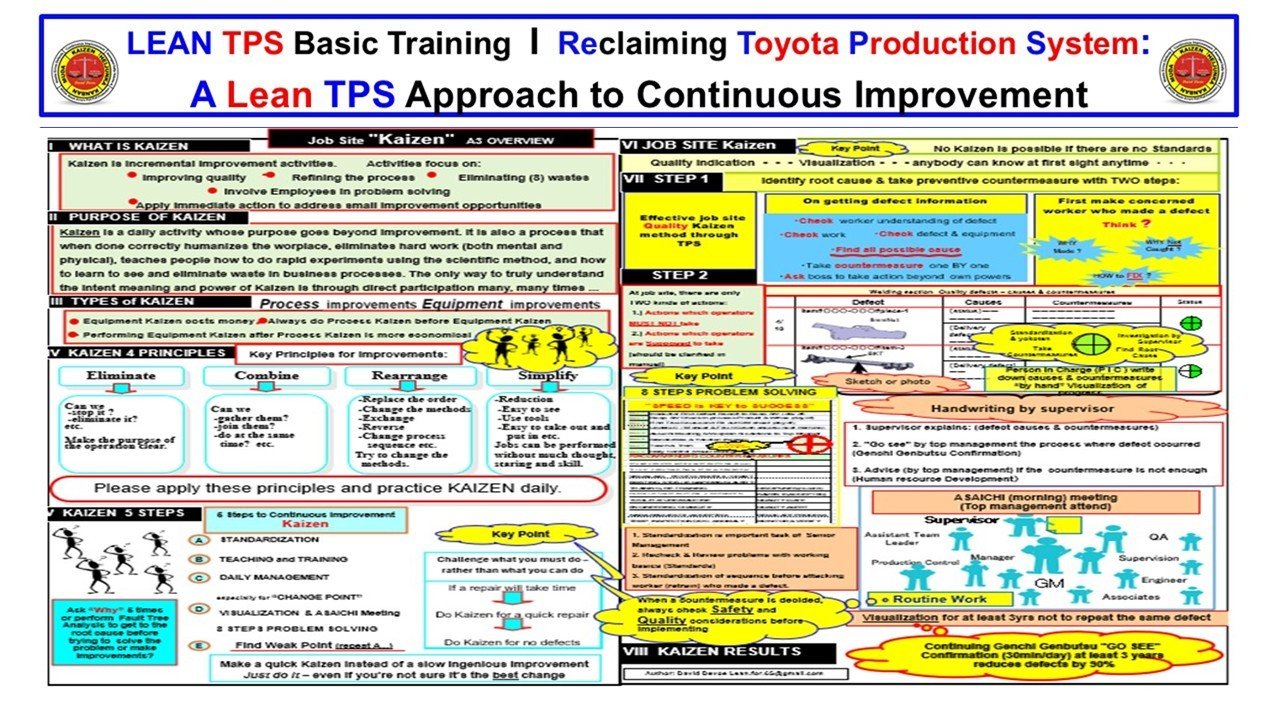

The Kaizen A3 organizes thinking around four key principles: Eliminate, Combine, Rearrange, and Simplify. These principles provide direction for improvement. Eliminate what adds no value. Combine activities that can be done together. Rearrange the order to improve flow. Simplify to reduce effort and make work easier to understand. When these principles are applied consistently, waste disappears and stability grows.

The A3 also highlights the importance of standardization. Kaizen does not exist without a standard. The standard defines what should happen. Kaizen improves what can happen. Without standards, change is random and cannot be sustained. The A3 teaches that the next improvement begins only after the new method is standardized. This cycle turns every improvement into a foundation for the next.

At the center of the A3 is the eight-step problem-solving method. It starts with clarifying the problem and identifying root causes through Genchi Genbutsu, direct observation at the workplace. Countermeasures are tested quickly and recorded visually on the A3. Each action links to a cause, not a guess. Supervisors write their countermeasures by hand. This simple act reinforces ownership and reflection. Leaders review progress in daily Asaichi meetings where problems and countermeasures are shared openly.

The Kaizen A3 also shows how improvement is supported through communication. Charts and visuals show safety, quality, delivery, and cost results. Handwriting by supervisors, photos of countermeasures, and color-coded checklists create transparency. These details turn the A3 into a coaching tool. A leader can stand beside an operator, review the sheet, and discuss what worked, what failed, and what can be learned. The form becomes a living record of thinking, not just a report.

One of the most important lessons within this A3 is that Kaizen connects people to their work. It gives purpose and meaning by showing how each improvement contributes to safety, quality, and flow. It also creates confidence. People learn that they can identify a problem, propose a change, and verify results. Over time, this practice shapes behavior and builds trust across the team.

When viewed through the Lean TPS lens, the Kaizen A3 is more than a tool. It is a visible reflection of respect for people and continuous improvement. It shows how learning happens through doing and how leadership grows by developing others. Every completed A3 is a story of shared learning, captured on one page, that continues to teach long after the work is done.