The A3 is one of Toyota’s simplest and most powerful tools. It is a single sheet of paper that captures the entire story of a problem, the countermeasures, and the results. Inside Toyota, the A3 became more than a report. It became a common language that connected people, taught thinking, and preserved learning across time and generations.

When I began my own Lean TPS training under Sam Nomura, I saw how the A3 functioned as both a teaching method and a management system. Each section of the form—background, current condition, target, analysis, countermeasures, implementation, and follow-up—was a step in disciplined thinking. Nothing was added for style. Every word, chart, and graph had a purpose. When leaders and team members stood around an A3 at the Gemba, they could see the same facts, agree on the same problem, and learn from the same logic.

The strength of the A3 format lies in its ability to make thinking visible. It translates the PDCA cycle Plan, Do, Check, Acton, to one page. The left side represents the Plan: understanding the problem, clarifying the target, and analyzing the root cause. The right side represents Do, Check, and Act: implementing countermeasures, verifying results, and locking in learning. By forcing everything into one structured flow, the A3 eliminates vague discussion and focuses everyone on fact-based problem solving.

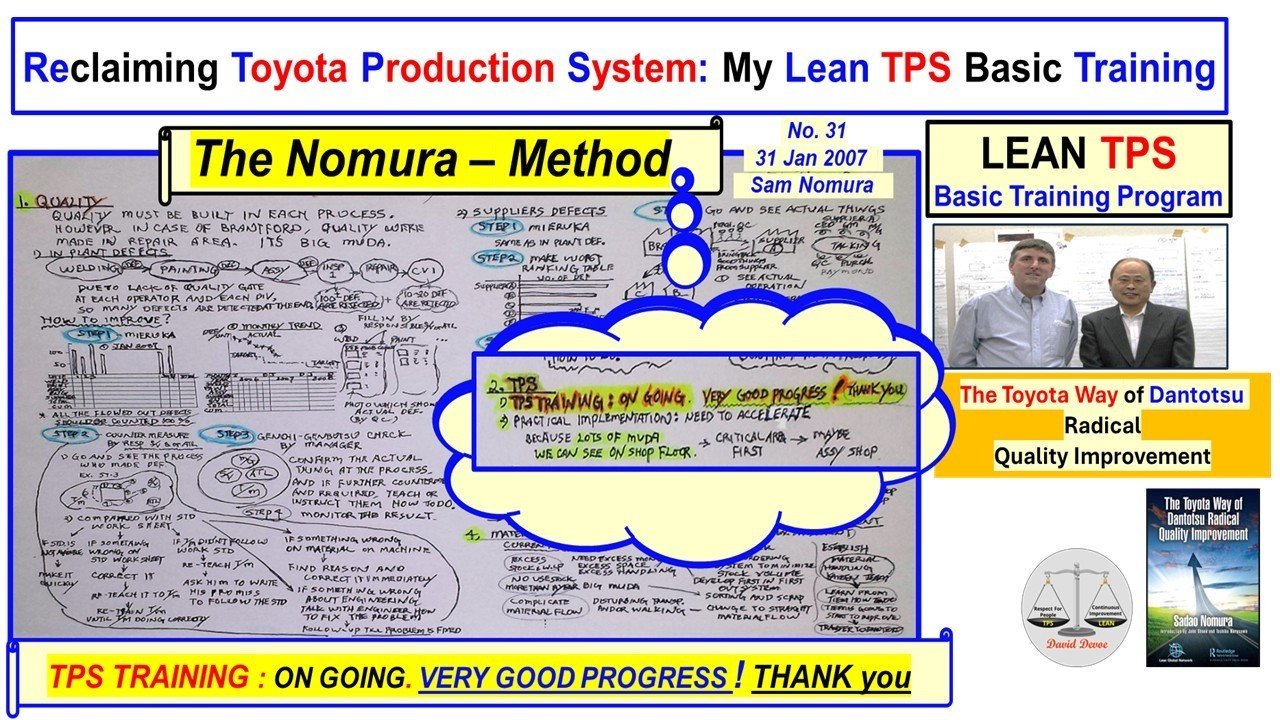

Sam Nomura taught us that every A3 tells a story, and that story must stand on its own years later. His handwritten A3 from 2007 remains one of the clearest examples of this discipline. It recorded the quality issues faced in Brantford, the countermeasures applied, and the progress made in TPS training. In a few sketches and notes, it captured what was happening, why it mattered, and how the team responded. Nothing was hidden in a report or buried in slides. The A3 itself became the permanent record of learning.

At Toyota, this practice preserved wisdom. The A3 made it possible to hand down lessons without distortion. A supervisor could study an old A3 and understand how previous teams solved problems, what standards were set, and what thinking led to success. This continuity turned individual improvements into organizational knowledge. The A3 became a form of cultural memory, storing the reasoning behind every improvement and every failure.

The Nomura A3 also reveals another truth about Lean TPS: improvement is not a single event. It is an ongoing process of reflection and correction. The handwritten notes “TPS training ongoing, very good progress, thank you” show that progress was never about completion, but continuation. Each A3 served as both a snapshot and a milestone, marking where the team stood in its journey toward Dantotsu, or radical quality improvement.

This is why the A3 remains central to Lean TPS today. It is not about documentation. It is about thinking. It teaches how to see the problem, how to reason from cause to countermeasure, and how to verify results with evidence. More importantly, it builds a habit of reflection that develops people at every level. Leaders do not tell others what to fix. They coach others to think and record their own learning through the A3 process.

Across decades, Toyota has used the A3 to teach, align, and sustain improvement. Whether applied to 5S, Kaizen, Jishuken, or large-scale production challenges, the purpose remains the same: to make problems visible, connect people through shared understanding, and preserve the knowledge gained through action. The A3 format continues to demonstrate that the true strength of Lean TPS is not in tools or templates, but in disciplined learning that passes from one generation to the next.