The project began with a simple objective: fix the billing delays.

By the time we started, more than two million dollars in change order billing was trapped in the system. Jobs were complete, but the cash was stuck. Project managers had agreed to changes, yet documentation was incomplete, inconsistent, or lost. Accounting could not close jobs, and without closure, holdback payments could not be released.

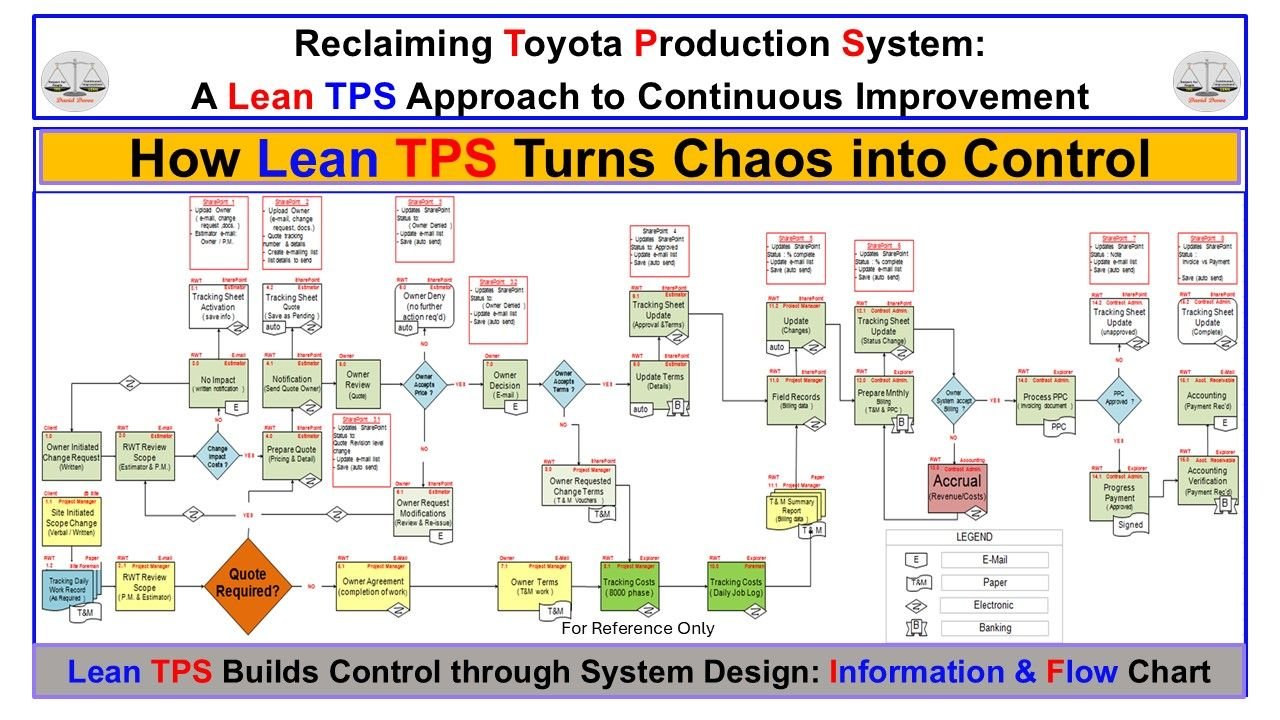

At first, leadership believed the solution was administrative. But when we created the current state Information and Flow Map, the real problem became visible. Billing was not one process; it was five disconnected ones. Estimation, field management, contract administration, accounting, and project control all worked independently. Documents moved, but not in sequence. SharePoint was used as storage, not as a control system. There was no standardized work, no rhythm, and no ownership of the end-to-end process.

To restore control, we applied Lean TPS system design. In the Obeya room, we mapped every action, decision, and approval point. Each team described their real work, not what procedures claimed was happening. Together, we exposed rework loops, missing approvals, and delays. We followed the rule of Genchi Genbutsu: go and see. Every delay had a cause, and every cause had a location in the flow.

The A3-based Information and Flow Map revealed the structure behind the chaos. It showed how change orders were initiated, reviewed, priced, approved, tracked, billed, and finally paid. This visibility turned confusion into sequence. Each process box and decision diamond represented a clear responsibility. Each link represented the flow of information, cost, or approval.

We then built countermeasures grounded in standardization.

• The change order transmittal was redesigned with built-in SharePoint triggers.

• The cost code database was rebuilt to remove ambiguity.

• The Work on Hand report was automated to update daily.

• Hour-by-hour checks exposed bottlenecks before they caused delay.

When the new flow went live, every stakeholder could see their role. Estimators knew when change reviews were due. Project managers could confirm status in real time. Accounting could verify completion and issue invoices with confidence. The system no longer depended on individuals remembering steps. It worked because the process itself carried control.

The results were immediate and measurable. Change order billing came under control. Jobs closed on time. Holdback payments were released without dispute. Cash flow improved, and confidence returned. The process that once caused daily frustration became a source of stability.

The transformation earned the Innovation of the Year Award. But the award was secondary to what it represented: a system rebuilt on Lean TPS principles. The achievement was not the elimination of errors, but the creation of structure that prevented errors from recurring. That is the true meaning of Lean TPS designing systems that make problems visible, enable response, and restore trust through stability.