When I first began implementing Standardized Work inside Toyota, I was given more than a form. I was given a discipline. The Standardized Work Audit Template was one of the earliest tools I used to build capability in a work cell. At Takahama and later at BT Raymond, I learned that without a structured way to see the reality of work, improvement efforts dissolve into opinion and shortcuts. At Toyota, Standardized Work was never about compliance. It was a way to teach leadership and problem solving at the Gemba. It created stability, clarity, and capability, which are the foundation of the Toyota Production System.

On many lines, the reality was far from ideal. Work instructions were often hidden, outdated, or inconsistent. Associates could not always locate their Standardized Work Books. Summary and Detail Element Sheets were incomplete. Takt Time was not verified. Quality Gates were missing or not clearly documented. What appeared organized from a distance broke down under closer observation. Without structure, problems stayed invisible, and leadership had no consistent way to coach or confirm.

The gap was not effort. Associates worked hard and cared about their performance. Leaders were committed to improvement. The missing element was discipline. We lacked a consistent method to confirm whether each station was aligned with Standardized Work. This was not a documentation problem but a visibility problem. If books were not current, if cycle time drifted, or if key points were forgotten, improvement became fragile. Standardized Work must always reflect the best known method today. When it is left unverified, it loses its power to drive learning.

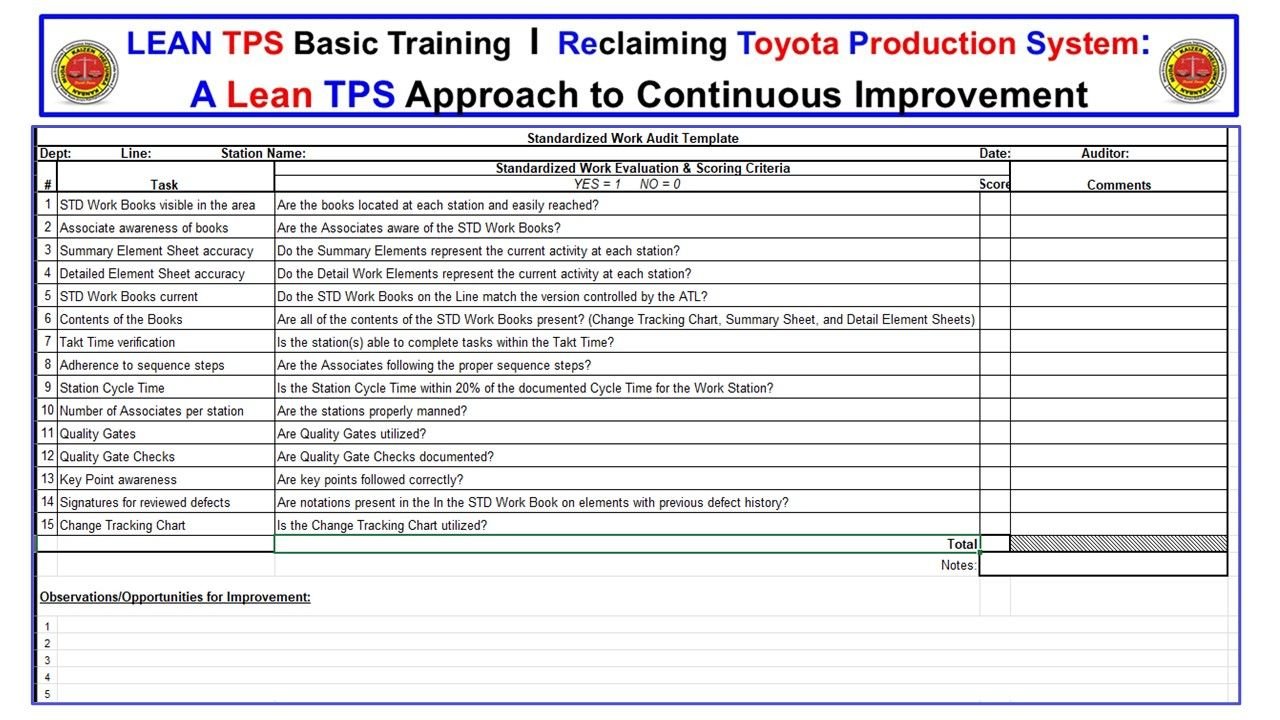

To close this gap, we developed a 15-question Standardized Work Audit. Each question could be answered Yes = 1 or No = 0. The goal was not to grade people but to expose weaknesses in the system. Every question asked something fundamental: Are the Standardized Work Books visible? Are associates aware of them? Do the Summary and Detail Elements match the actual condition? Is Takt Time verified? Are Quality Gates used and documented? Are signatures recorded for reviewed defects? Is the Change Tracking Chart active and current?

Each audit revealed the health of the process. A low score did not trigger blame. It triggered coaching. Leaders stood at the line with associates, reviewed each question, and corrected the gaps together. The audit became a shared language between operators and supervisors. It allowed facts to replace assumptions. The most important outcome was not the score but the conversation that followed. Over time, the books became accurate, the work stabilized, and problems surfaced faster. Standardized Work moved from being a document to being a living system.

As this discipline matured, the atmosphere changed. Associates trusted that the instructions they followed were correct. Team Leaders understood that their role was to maintain the standard and support improvement. Problems that once remained hidden became visible and solvable. When everyone used the same reference, improvement gained structure and credibility. The audit was not about passing inspection. It was about learning to see and respond as one team.

Years later, when I look back at these early templates, I see more than checkboxes and forms. I see how Toyota used structure to teach leadership. The audit was a framework to practice Respect for People and Continuous Improvement in daily work. It made expectations clear, gave feedback meaning, and turned management into coaching. This is why Standardized Work is called the foundation of Lean TPS. It transforms the workplace from reactive activity to deliberate practice. It creates confidence that every process can improve because it is seen, measured, and understood.

The power of Standardized Work is not in the paper. It is in the habit of checking, reflecting, and improving together. At Toyota, this was the essence of learning. Structure was not control. It was respect.