The Jishuken A3 represents Toyota’s most advanced form of learning by doing. It captures the leadership development process where improvement is studied, tested, and verified at the workplace. Each A3 tells the story of how leaders build capability by solving real problems. This example from the Brantford Reach Truck Assembly line records the Week 1 activity report of a full Jishuken cycle.

The purpose of the Brantford Jishuken was to strengthen flow in the tractor assembly process while developing the next generation of problem-solving leaders. The team’s objective was not only to improve performance but to deepen understanding of Lean TPS fundamentals. The A3 layout shows how Toyota organizes this learning: a clear theme, a defined purpose, data on current condition, and measurable targets. Every number on the form links directly to an observation at the Gemba.

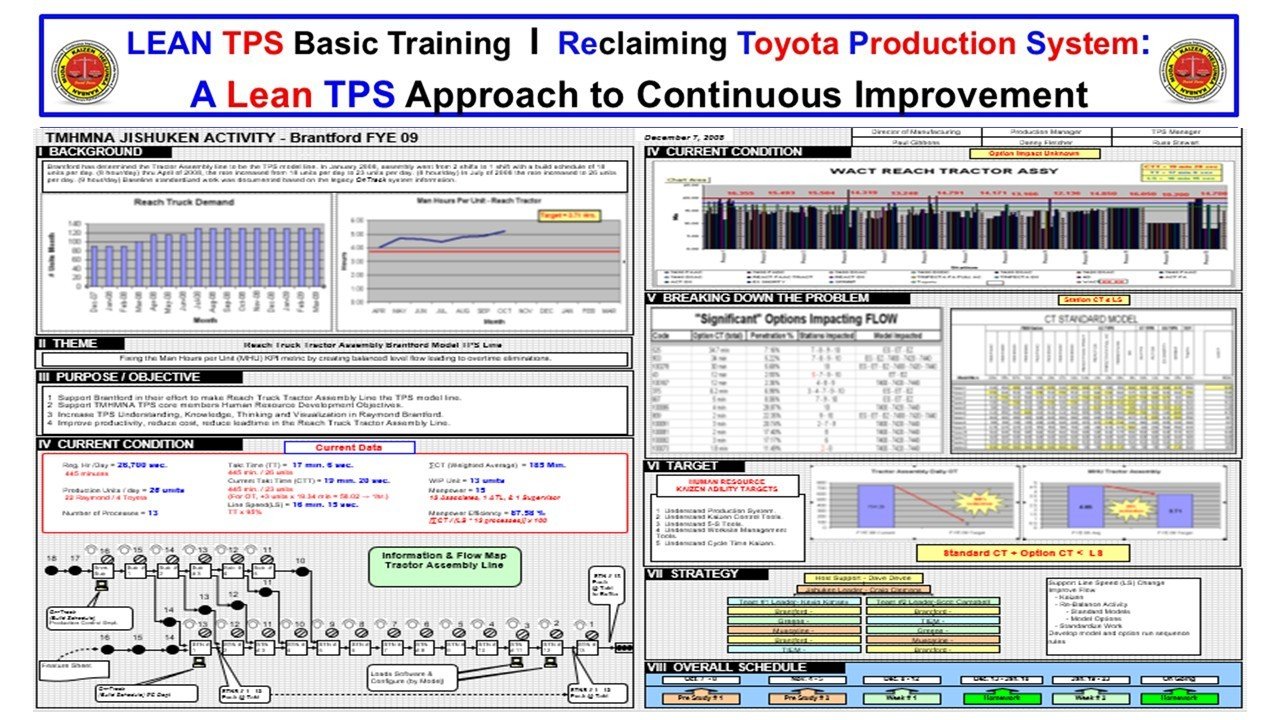

The background section describes the context. The line had variable flow and unbalanced work. Main hours per unit were unstable, leading to overtime. Data were collected on takt time, work sequence, and manpower balance. The current condition section displays this analysis visually, with charts showing daily reach truck demand and main hours per unit. This visual storytelling allows everyone on the team to see the problem in the same way.

In the “Breaking Down the Problem” section, the Jishuken team identified the significant options that were impacting flow. These were analyzed using data from the standard cycle time model. By comparing actual work sequence against the standard, the team located variations that caused unevenness. This process of breaking down the problem is what differentiates Jishuken from normal kaizen. It forces leaders to see the system as a whole, not as isolated issues.

The target section defines both human and process objectives. Human Resource Ability Targets are listed alongside measurable production goals. This dual focus is what makes Jishuken unique. Improvement is achieved through developing people, and people are developed through structured improvement. The ability targets include skills in standard work design, waste identification, and cycle time analysis. As the process improves, leadership capability grows with it.

In the strategy and schedule sections, the plan is laid out week by week. Each task is assigned to team members with deadlines and expected outcomes. The A3 serves as a shared roadmap that keeps learning and execution connected. Through the use of flow maps and visual control, progress is made visible to everyone involved. This transparency builds accountability and strengthens teamwork.

The Jishuken A3 also shows the connection between Toyota’s three main principles: visualization, standardization, and leadership participation. By collecting data directly at the line, analyzing it visually, and linking countermeasures to actual conditions, the team learns through experience. Leadership presence at the Gemba ensures that discussion remains fact-based and action-oriented. Every step in this A3 reflects Toyota’s philosophy that learning is earned through direct observation and experimentation.

When viewed as a whole, the Jishuken A3 is more than a record of improvement. It is a structured reflection of leadership growth. Each graph, table, and target connects people to purpose. It shows how Toyota builds capability not through classroom instruction but through the discipline of solving real problems. The form preserves both the data and the learning so that future teams can study, compare, and improve upon it.