The Jishuken A3 Mid-Term Report captures the turning point in structured improvement. At this stage, the team has moved beyond data collection and is now applying countermeasures. The focus shifts from observing problems to testing solutions. The A3 documents both progress and learning, connecting technical results to leadership development.

In the Brantford Reach Truck Tractor Assembly Line Jishuken, the goal was to stabilize production by creating balanced flow and reducing overtime. The first phase revealed uneven work distribution and high variation in main hours per unit. By the mid-term stage, the team had implemented targeted improvements that began to produce measurable results. The A3 shows how visualization, teamwork, and disciplined analysis turned learning into progress.

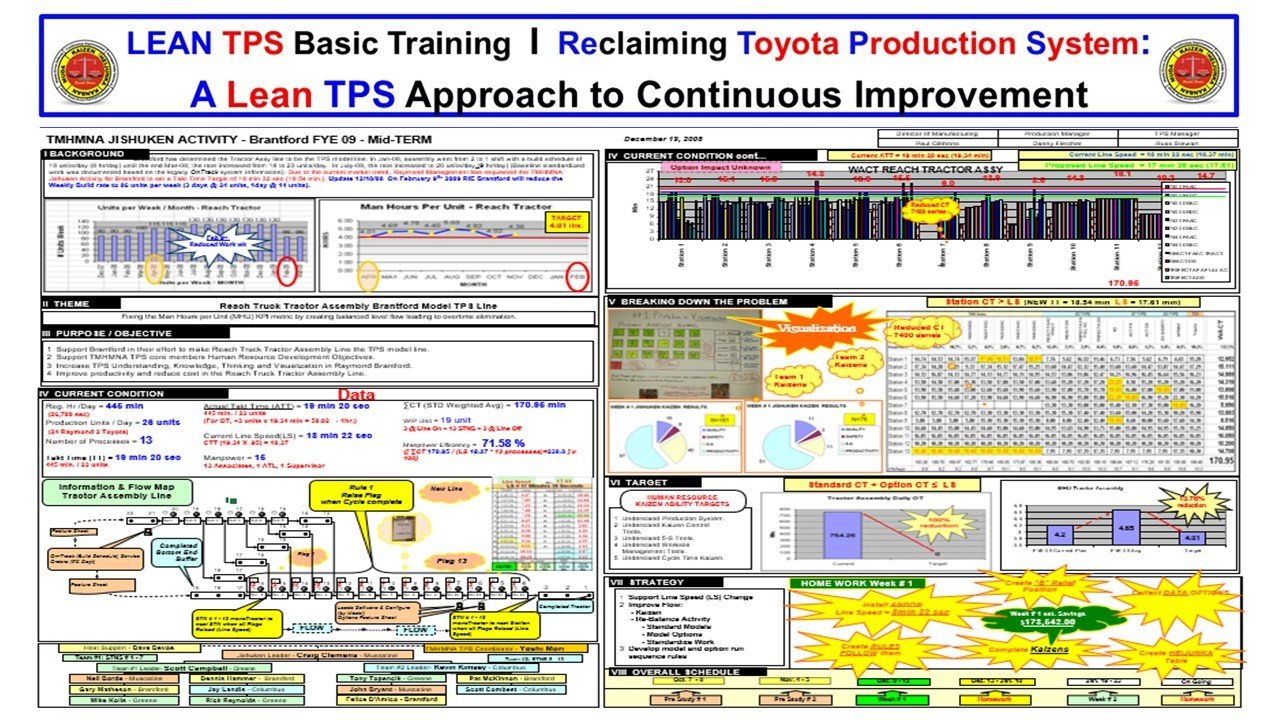

The background and current condition sections display the improvement in line performance. Charts show a reduction in main hours per unit and clearer rhythm in daily output. The bar graphs and flow diagrams illustrate how takt time, standard cycle time, and workload balance became visible to all. These visuals are the core of Toyota’s thinking process. They transform numbers into shared understanding.

In the “Breaking Down the Problem” section, new visuals appear directly from the shop floor. Kaizen team boards, process maps, and color-coded analysis sheets reveal how problems were segmented and prioritized. This stage emphasizes the power of visual management. When every team can see their progress, ownership grows. Visualization is not decoration. It is communication. It aligns leadership, supervisors, and operators around the same facts.

The target section continues to balance human development with process goals. Human Resource Ability Targets are listed beside production indicators. The team’s learning goals include improved problem-solving skill, stronger Standardized Work capability, and faster recognition of abnormalities. Each improvement task becomes a training opportunity, reinforcing the Toyota belief that every problem is a chance to develop people.

In the strategy section, the A3 records how the team structured weekly assignments, defined responsibilities, and verified results. Homework boards, review schedules, and Kaizen summaries connect the plan to daily action. Mid-term analysis shows that flow had improved by more than 70 percent, saving both labor hours and rework. However, the true success was not in the savings but in the learning. Leaders began to see variation as information, not failure.

The Jishuken Mid-Term A3 also documents leadership behavior. Supervisors and managers conducted Genchi Genbutsu at the workstations, confirming data directly with associates. This presence created trust and accelerated learning. Each problem was discussed at the point of occurrence, with visual evidence guiding decisions. The culture shifted from reaction to reflection.

By the midpoint of the Jishuken, the team had transformed the workplace into a learning environment. Balanced flow replaced bottlenecks, and improvement became routine. The A3 captures this transition in detail, preserving both the technical and human progress. It shows that continuous improvement is not achieved through a single project but through the habit of structured learning at the Gemba.