The Jishuken A3 Final Report represents the completion of a full cycle of learning through structured improvement. It captures the results of teamwork, leadership, and disciplined analysis. More than a record of performance, it is a reflection of how people developed their problem-solving ability through the process.

At the Brantford Reach Truck Tractor Assembly Line, the Jishuken began with instability in work balance and overtime. The objective was clear: create balanced flow, reduce variation, and strengthen understanding of Lean TPS fundamentals. The A3 structure guided the team through every phase of this journey, from observation and problem breakdown to countermeasure and reflection.

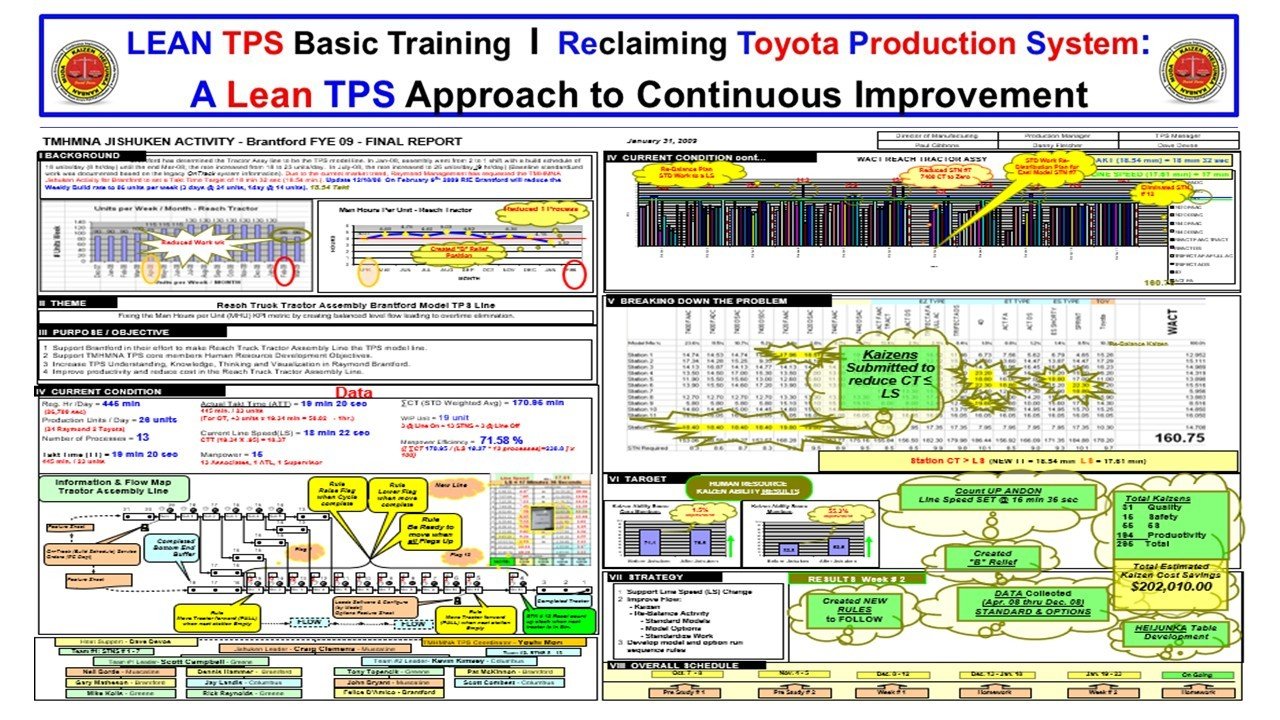

The background data show the transformation in flow and productivity. Main hours per unit dropped steadily as the team applied Kaizen to reduce waiting time, motion waste, and rework. Charts in the current condition section show smoother rhythm across the line. What began as irregular output evolved into a stable, predictable system. The graphs make improvement visible, converting complex data into a story of learning.

In “Breaking Down the Problem,” the A3 shows how the team analyzed the causes behind uneven cycle times. Each bar and data point was linked to a real observation at the workplace. The use of visual highlights such as color-coded bars, pie charts, and line maps helped teams recognize the relationship between flow and workload. By connecting process data to daily work, leadership learned to make decisions based on facts rather than assumptions.

The target section continues the dual focus that defines every Jishuken: process and people. The team tracked measurable results in productivity, safety, and quality while also recording leadership skill growth. These Human Resource Ability Targets ensured that improvement did not stop at technical gains. Supervisors, engineers, and team leaders learned how to apply PDCA thinking, confirm standards, and sustain results.

The strategy section outlines how the final improvements were implemented. Each Kaizen action was linked to a specific cause identified earlier. Countermeasures were tested, confirmed, and then standardized. The flow map was updated to reflect new rules, visual controls, and standard cycle times. As the team progressed, results were reviewed in weekly meetings with full participation from the line to management. This closed the loop between learning and leadership accountability.

The results section summarizes the impact of the Jishuken. Over fifty Kaizen activities were completed, addressing safety, quality, and flow. Estimated savings exceeded $200,000, but the deeper achievement was the development of a capable leadership team. Supervisors learned to lead through data, confirm reality through Genchi Genbutsu, and manage improvement as a system.

The final reflection shows how the A3 serves as both record and teaching tool. Each section connects evidence, countermeasure, and learning. When viewed together, these A3s form a complete story of transformation that others can study and apply. The Brantford Jishuken demonstrates that real improvement occurs only when learning and leadership progress together. The A3 preserves that progress so future teams can continue the journey.