The A3 is one of the most enduring tools inside the Toyota Production System. It captures an entire improvement story problem, analysis, countermeasures, and results—on a single page. At first glance, it seems simple. But within Toyota, this format represents a disciplined way of thinking that connects every level of leadership, teaches people how to reason from facts, and preserves knowledge for the next generation.

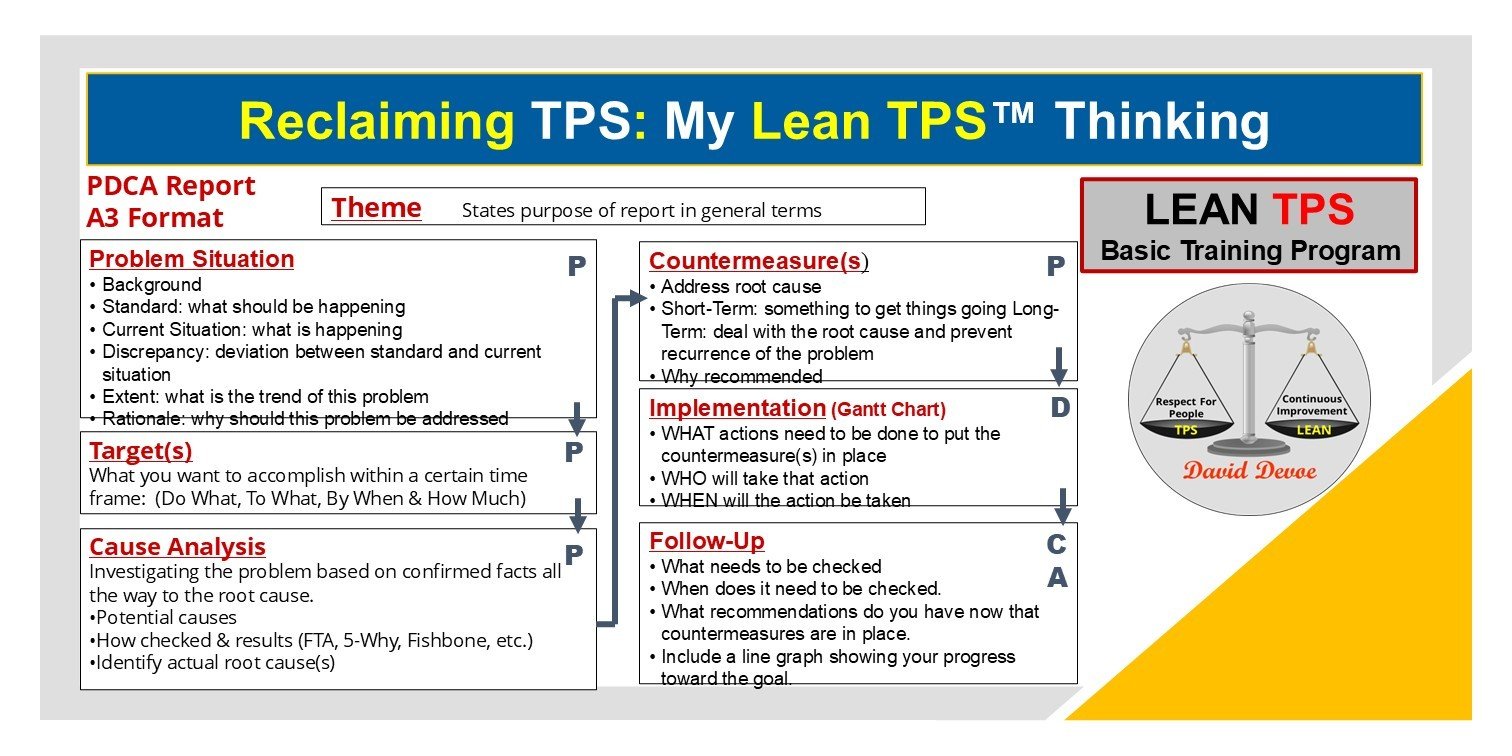

The A3 format reflects the PDCA cycle: Plan, Do, Check, Act. On the left side, we define the Plan through the problem situation, targets, and cause analysis. On the right side, we carry out Do, Check, and Act through countermeasures, implementation, and follow-up. Each step is written concisely, supported by data, and designed to make the logic clear. This balance of structure and simplicity forces clarity and prevents overcomplication.

When I was first trained at Toyota Industries in Takahama, Japan, I learned that the purpose of the A3 was not documentation. It was development. Every A3 was a coaching tool that guided the learner to think scientifically. Leaders did not correct the form—they challenged the thinking. They asked questions: What is the problem? What standard should exist? What facts prove the gap? What is the cause? What evidence supports the countermeasure? This process turned improvement into a shared study between leaders and team members.

Each section of the A3 has a clear purpose. The Problem Situation defines what should be happening versus what is happening, and shows the trend. The Target sets a measurable condition to be achieved within a defined timeframe. The Cause Analysis identifies the true root causes, verified by observation and data, not assumptions. The Countermeasures address these causes directly, with both short-term stabilizing steps and long-term prevention. The Implementation Plan specifies who will act, what will be done, and when. The Follow-Up confirms effectiveness, adjusts the standard, and captures learning.

Through this flow, the A3 transforms abstract ideas into concrete action. It replaces opinion with fact, argument with logic, and delay with structured progress. At Toyota, leaders often posted A3s on boards near the Gemba so that anyone could review the thinking and the results. Over time, these sheets became living archives of improvement. A visitor could walk into any area and understand what problems were being addressed, what actions were taken, and what was learned.

The real strength of the A3 is continuity. Each completed A3 becomes a reference point for the next challenge. It allows future teams to see what worked, what failed, and why. The knowledge does not disappear when people move on—it stays visible in the logic and evidence recorded on paper. This is how Toyota preserved both knowledge and wisdom: by teaching people to think in a way that can be read and understood years later.

When applied consistently, the A3 format builds alignment across an organization. It connects engineers, supervisors, and operators in a common problem-solving language. It strengthens leadership by making decisions transparent and accountable. And it reinforces the two unshakable pillars of Lean TPS: Respect for People and Continuous Improvement. The A3 helps leaders practice respect by developing others’ thinking. It sustains improvement by creating a permanent record of cause and effect.

For Toyota, the A3 is not just a report it is the written form of PDCA thinking. It is the link between theory and practice, between action and reflection. This is why the A3 continues to serve as a foundation for learning and improvement across generations. It is not a relic of the past, but a living guide to how people can see, think, and improve together.