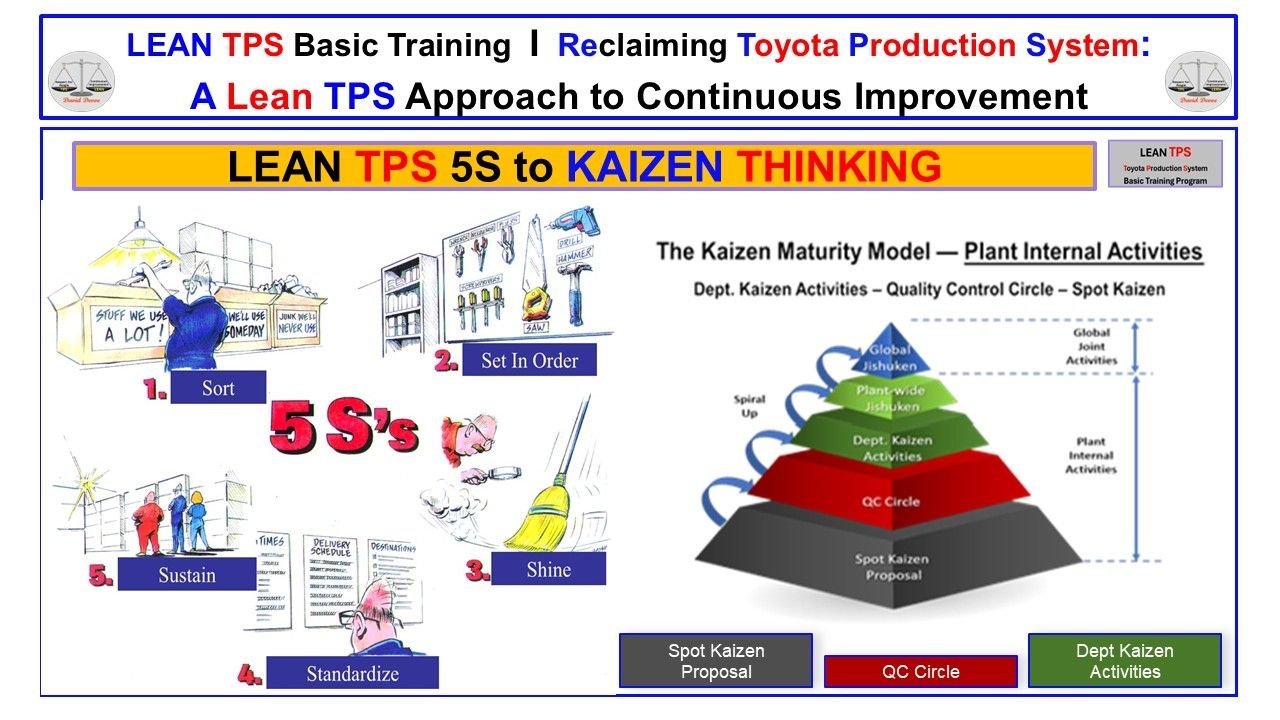

In Lean TPS, every transformation begins with structure. 5S Thinking is the foundation. It is not cleaning or preparation. It is the discipline that allows a system to see, think, and improve.

During my time with Toyota L&F in Takahama, Japan, and later through Jishuken activities at Toyota BT Raymond and the Toyota Material Handling Manufacturing North America Working Group, we always began with 5S. It was never optional. It was the foundation for flow, quality, and leadership development.

5S Thinking builds the conditions for visibility and control. It aligns people to a common structure and reveals the real condition of work. When applied correctly, it is not about order for appearance. It is about seeing what is happening and understanding why.

Inside Toyota, the sequence was fixed:

- Establish 5S.

- Confirm stability.

- Introduce Standardized Work.

- Build flow and pull.

- Teach Kaizen.

Every improvement activity relied on that foundation. Without 5S, there was no visibility. Without visibility, there was no control. Without control, leadership had nothing to teach or sustain.

Each element of 5S has a specific purpose:

- Sort (Seiri): Remove unnecessary items.

- Set in Order (Seiton): Arrange what remains so problems are visible.

- Shine (Seiso): Clean to reveal wear, damage, or leaks.

- Standardize (Seiketsu): Create visual routines that keep order.

- Sustain (Shitsuke): Maintain the habit through leadership confirmation and team ownership.

When teams practice 5S correctly, it changes how they see work. Problems surface faster. Standards become clearer. Leadership gains a way to coach rather than control.

This is why Lean TPS training begins here. 5S Thinking exposes friction, builds shared routines, and prepares the environment for improvement. It is not an entry-level activity. It is system design in its most practical form.

If your workplace struggles with inconsistency or hidden waste, the first move is not automation or new tools. It is rebuilding structure through 5S Thinking. That structure is what makes flow and Kaizen possible.