Introduction

Every Lean TPS journey begins with structure. In my experience working inside Toyota and leading Lean TPS implementations in Canada, Japan, and North America, one principle has proven universal: improvement cannot start in chaos. The first step is to stabilize the environment through 5S Thinking.

At Toyota, 5S was never introduced as a cleaning activity or an early awareness program. It was a core discipline that made the system visible, measurable, and teachable. Without it, flow, quality, and leadership cannot function effectively. The Lean TPS approach I learned and practiced always started here.

What 5S Thinking Really Means

5S Thinking is the process of creating and sustaining conditions that make abnormality visible and action possible. Each “S” represents a behavioral step toward stability:

- Sort (Seiri): Remove everything unnecessary from the work area. This clears space and ensures that only essential items remain. It prevents waste and reveals what is out of place.

- Set in Order (Seiton): Designate locations for tools, materials, and equipment. When everything has a defined home, deviations are immediately visible. This step is where flow begins.

- Shine (Seiso): Clean not for appearance, but for detection. Surfaces free of dust or oil show leaks, wear, or damage early. This enables proactive maintenance and quality control.

- Standardize (Seiketsu): Develop simple, visual routines to maintain the first three S’s. Shared standards prevent backsliding and ensure everyone sees normal versus abnormal the same way.

- Sustain (Shitsuke): Build discipline through leadership follow-up and team ownership. Sustain is not about posters or slogans; it is about habit, respect, and shared accountability.

When practiced properly, 5S does not only organize the workspace. It builds the foundation for thinking. It teaches people to observe, to question, and to take corrective action immediately.

Why 5S Comes Before Flow

Inside Toyota, there was never a debate about sequence. We did not launch Just-In-Time, Kanban, or Standardized Work until 5S was established. Without visibility, there is no way to see waste. Without order, there is no way to control flow. Without structure, leadership has nothing to teach or sustain.

At Toyota BT Raymond, I supported teams through early TPS training under the guidance of Mr. Sadao Nomura and the Toyota Material Handling Manufacturing Working Group. Every Jishuken activity began with 5S confirmation. It was not a warm-up exercise. It was a prerequisite to learning.

By building 5S first, teams gained the ability to see variation. Leaders learned to coach at the source. And problems were addressed before they spread. This structured approach allowed flow and Kaizen to emerge naturally, not through events, but through daily discipline.

5S in the Lean TPS Maturity Model

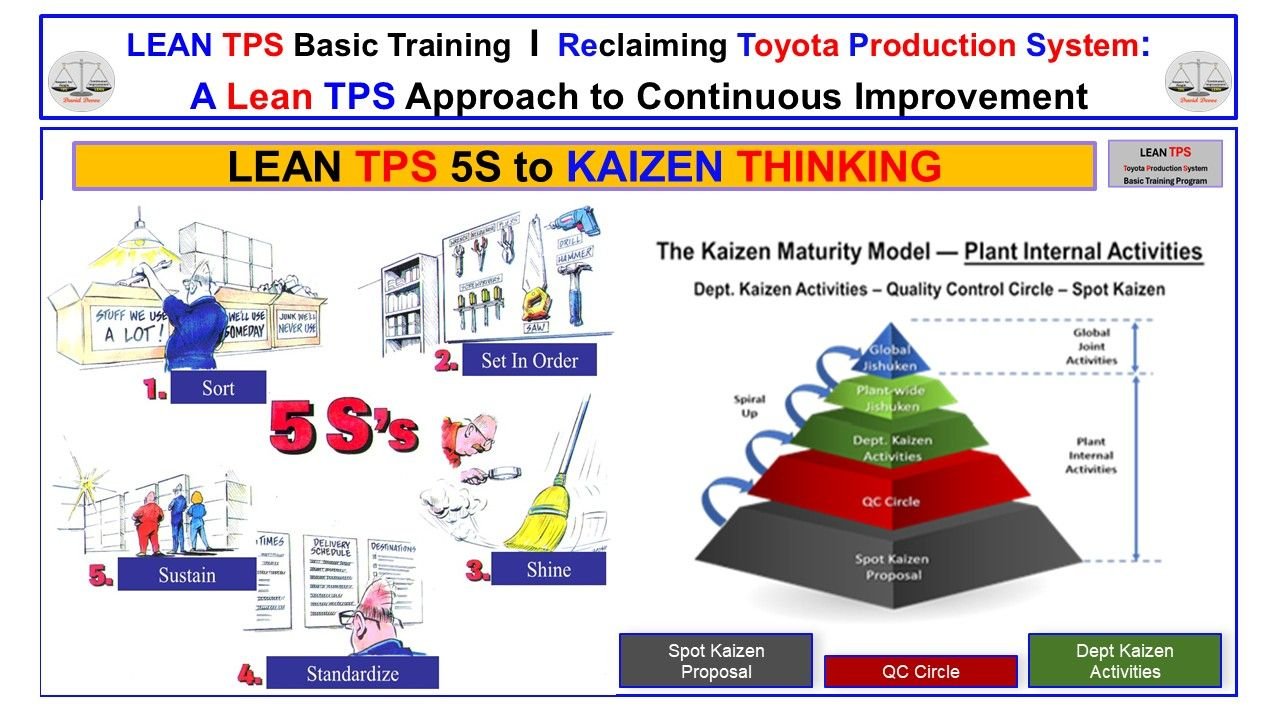

The visual in this article connects 5S directly to the Lean TPS Kaizen Maturity Spiral. Spot Kaizen, QC Circles, and Department-level improvements cannot function without stability. 5S creates the shared foundation that supports all higher-level activities. It turns individual effort into collective learning.

At the bottom of the maturity model, 5S supports Spot Kaizen Proposals. Employees can see and fix small problems quickly because their environment is organized. As teams advance, they form QC Circles and Department Kaizen Activities, where shared standards make cross-functional improvement possible. Eventually, 5S Thinking supports Jishuken — leader-led improvement studies that develop capability at the organizational level.

Each step depends on the clarity established by 5S. When 5S is weak, problems stay hidden. When 5S is strong, learning accelerates.

Leadership’s Role in 5S Thinking

Sustaining 5S is not the responsibility of employees alone. Leaders play a critical role in confirming, teaching, and modeling the behavior. The term “leadership confirmation” at Toyota refers to structured, daily observation at the Gemba. Leaders are expected to verify conditions, provide feedback, and reinforce problem-solving behavior.

In practice, this means walking the floor daily, confirming that standards are visible, that tools are in place, and that the environment supports continuous improvement. The focus is not on inspection but on coaching. 5S is sustained by leadership presence and involvement, not by directives or audits.

5S as a Thinking Model

In modern workplaces, many organizations still treat 5S as a compliance exercise. They measure it through checklists or scoring systems. This approach misses the point. The goal of 5S Thinking is not order for its own sake. It is clarity — clarity of flow, responsibility, and abnormality.

When I teach Lean TPS Basic Training, I emphasize that 5S is a method for building capability. It develops the mindset of seeing. It trains people to recognize problems before they escalate. It is a human development process embedded in system design.

Applying 5S Thinking Today

In today’s hybrid and high-variation environments, 5S remains more relevant than ever. Many companies face challenges in consistency, communication, and workplace engagement. The simple act of restoring structure provides stability and confidence.

Whether in manufacturing, logistics, healthcare, or office settings, 5S Thinking establishes the foundation for flow. It allows leaders to manage visually, enables problem-solving at the source, and builds a culture that sustains improvement. The lesson from Toyota remains unchanged: 5S is not preparation for Lean. It is Lean.

Conclusion

5S Thinking is the first and most important step in Lean TPS. It creates order, reveals problems, and builds habits that lead to continuous improvement. Without it, no other element of the system can stand. When organizations adopt 5S as a way of thinking rather than a checklist, they create a visible, stable environment where learning and improvement can thrive.

In Lean TPS, 5S is not a project. It is a principle. It is where every improvement begins.