The 5S A3 represents the beginning of structured learning in Lean TPS. It captures how Toyota builds discipline and stability through visible order. The five steps, Sort, Set in Order, Shine, Standardize, and Sustain, form the base of every improvement activity. On the surface, 5S looks like housekeeping. In reality, it is the first lesson in seeing waste, understanding flow, and maintaining standards.

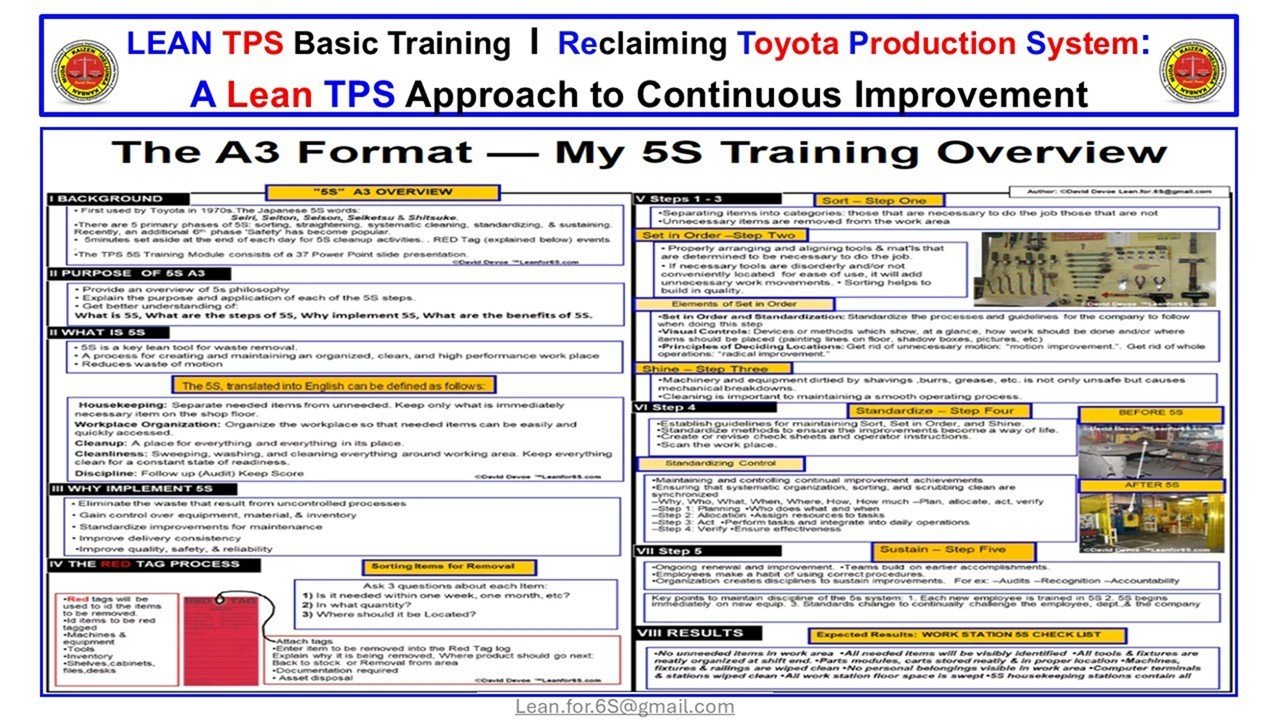

This A3 was designed to teach the 5S method as a complete learning cycle. The background explains the origin of the system in Toyota’s 1970s training programs and how it evolved from Japanese workplace culture. The purpose defines why 5S exists: to create a clean, organized, and safe environment that supports quality and efficiency. Each section of the A3 walks learners through the steps while connecting them to the deeper meaning behind the method.

Sort removes what is unnecessary. Every unneeded tool, fixture, or document hides a problem and adds waste. Set in Order arranges items by function and frequency of use so that work can flow without searching. Shine goes beyond cleaning. It is inspection through activity. Workers clean not to make things look good but to detect wear, leaks, or damage that could cause failure. Standardize turns the first three steps into visual routines that can be followed by anyone. Sustain builds the habit of discipline and accountability through daily practice and audits.

The A3 format transforms these steps into a clear visual process. On the right side, before and after photos show how order eliminates confusion. A disorganized tool area becomes a clean, labeled workspace where problems are instantly visible. This visual comparison teaches faster than words. The Red Tag section demonstrates how to start. Items are tagged, reviewed, and removed systematically, linking action to decision. This simple process trains the eye to distinguish between value and waste.

By documenting 5S in A3 form, Toyota made the learning visible. Each A3 tells a story that starts with disorder and ends with flow. The form captures not only the steps but also the purpose, results, and standardization that follow. It becomes a record of learning and a guide for coaching. When a new employee studies a 5S A3, they see more than procedures. They see thinking.

The 5S A3 also shows how improvement begins from the ground up. It teaches that order and safety come before efficiency. A stable, visual workplace allows everyone to see problems early and act immediately. This is why Toyota treats 5S not as a separate activity but as the starting point of every Lean TPS transformation. Without 5S, Standardized Work and Kaizen have no foundation. With it, every improvement stands on solid ground.

When leaders apply 5S with intent, they create an environment that supports respect and continuous improvement. People take pride in their workplace, understand their standards, and develop the discipline to sustain improvement. The 5S A3 captures this entire journey on one page. It shows that the foundation of Lean TPS is not technology or cost reduction. It is order, clarity, and human development through daily practice.