Daily Shopfloor Management, or DSM, is often mistaken for visual boards and short meetings. In reality, it is the daily structure that connects leadership, people, and process. It is how Toyota develops capability while managing production. DSM is the visible expression of the Toyota Way and the foundation of leadership standard work.

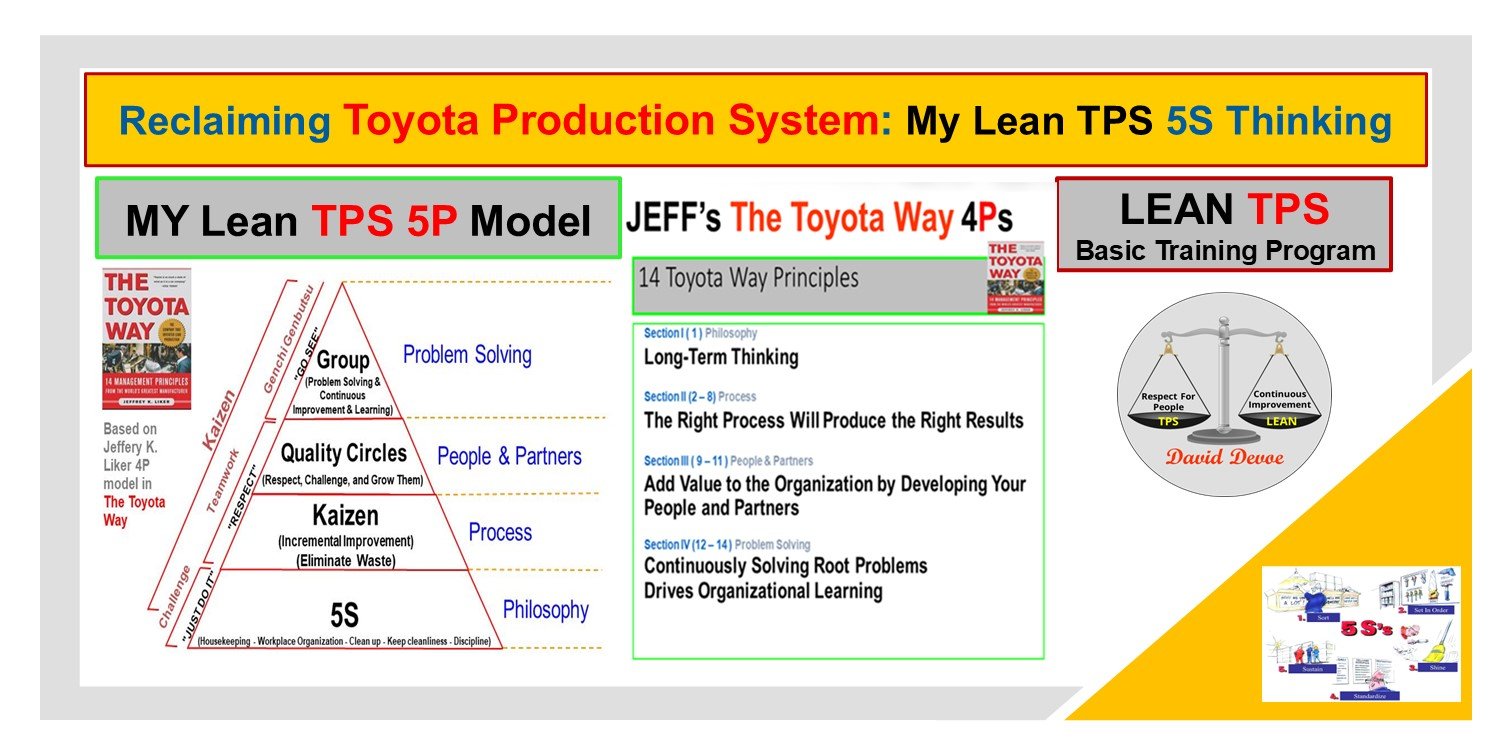

The strength of DSM is that it makes development a daily habit, not a separate event. Every check, every question, and every observation becomes an opportunity to teach and learn. In this way, DSM links directly to the 4P Model from The Toyota Way and expands naturally into the Lean TPS 5P Model: Philosophy, Process, People and Partners, Problem Solving, and Performance through Jishuken.

Philosophy

At the base of the system is long-term thinking. Leaders act with purpose beyond short-term results. The focus is on preventing failure through structure, not reacting after it occurs. DSM is one of the visible structures that keeps long-term philosophy alive in daily practice.

Process

Every DSM routine begins with process confirmation. Leaders make problems visible by walking the line, checking standards, and verifying flow. When a problem appears, it is not hidden. The team stops, studies, and learns. DSM is the mechanism that protects the standard and exposes instability before it becomes a defect.

People and Partners

Respect is shown through coaching, not instruction. Developing people is the primary role of leadership. DSM provides the framework for that development. Through TWI Job Instruction, Job Breakdown Sheets, and Skills Matrices, leaders ensure that knowledge is shared and that people can perform their work confidently. In Toyota, training is not a classroom exercise. It is a structured process that transfers skill through daily engagement and follow-up.

Problem Solving

At the heart of DSM is continuous improvement. Each meeting and Gemba walk is a learning cycle of PDCA. Leaders and team members work together to identify root causes, test countermeasures, and verify results. This shared discipline creates a culture where everyone contributes to improvement. The 5-Why, line checks, and Kamishibai cards are not tools. They are prompts that strengthen the habit of thinking deeply and learning from problems.

Performance through Jishuken

The fifth element of the Lean TPS 5P Model is Performance through Jishuken. This is where DSM evolves from management to leadership development. In Jishuken, leaders study their own systems, improve processes, and raise the capability of their teams. It is structured reflection and action in one. The daily discipline of DSM creates the conditions that make Jishuken effective, while Jishuken reinforces the leadership mindset that sustains DSM.

DSM shows the living relationship between leadership and people. It ensures that standards are taught, problems are visible, and improvement is constant. The most successful organizations understand that DSM is not about checking performance. It is about developing people who can improve performance. That is what builds trust, stability, and strength across generations.