Transferring Knowledge and Wisdom Through the Toyota Way

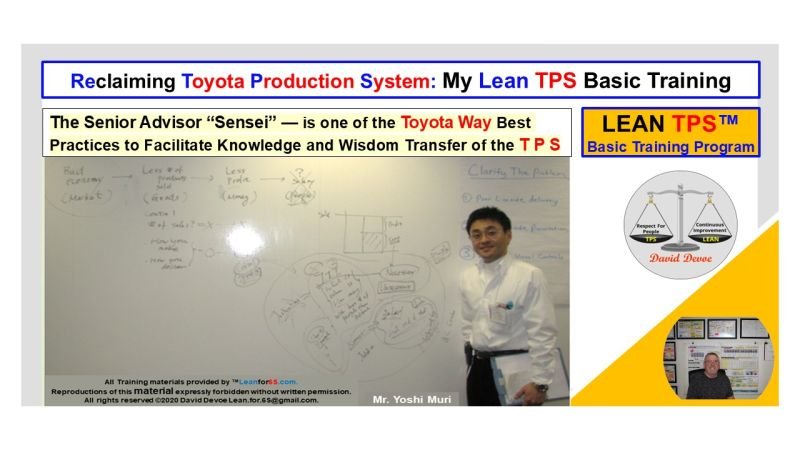

It is a privilege to share the influence of Mr. Yoshiyasu “Yoshi” Mori, one of my Toyota Production System (TPS) Sensei. Yoshi led the Jishuken activities at Toyota Material Handling Manufacturing North America (TMHMNA) and was personally recruited by Mr. Susumu “Sonny” Toyoda, then President of Toyota Industrial Equipment Manufacturing (TIEM).

Yoshi’s guidance shaped how I understand Lean TPS as both a production and leadership system. His approach to Jishuken was not about teaching tools but developing people. He believed improvement was not real unless it built capability in those who would sustain it. Every kaizen, every observation, and every reflection was part of a learning cycle.

When Yoshi led a Jishuken, he began by asking questions instead of giving answers. His method revealed waste in processes and gaps in leadership understanding. He taught that the role of a Sensei is not to fix problems but to teach how to see them. That principle continues to define how I approach Lean TPS today.

Working with Yoshi showed me that true TPS learning happens only through direct experience. Classroom explanations could not replace what was learned by standing at the Gemba, tracing flow, and asking why. He demonstrated that Lean TPS is not a toolbox—it is a disciplined way of thinking and developing people.

Yoshi Mori’s influence continues to shape how I teach, coach, and support organizations today. His lessons in respect, persistence, and scientific thinking remain a standard for how Lean TPS is practiced and taught at its highest level.