Handwritten Standardized Work Combination Table – Lean TPS Leadership Study Example

By David Devoe

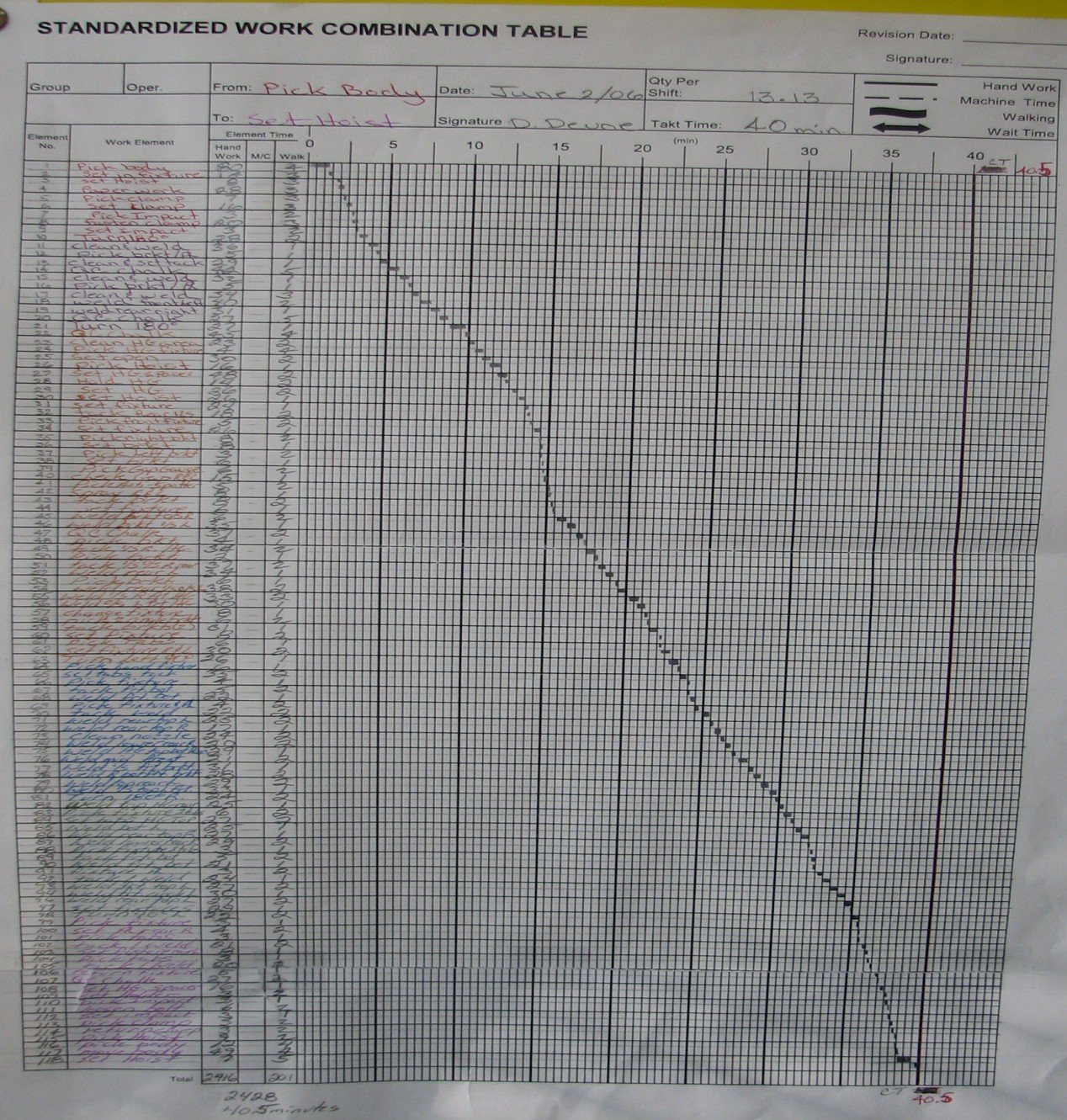

At Toyota Industries Corporation in Takahama, Japan, I learned that Standardized Work is not paperwork. It is the structure that connects people, machines, and materials in a balanced rhythm. The Standardized Work Combination Table, or SWCT, is the visual that makes that rhythm visible. It shows how time, sequence, and flow interact to create stability or reveal imbalance.

This handwritten SWCT was completed during my own Lean TPS leadership study at Toyota BT Raymond. Every line represents real work observed on the shop floor. Each element was timed and recorded to reveal the relationship between manual work, machine cycles, and walking. The purpose was not to fill out a form but to learn how to see. The handwriting itself shows that learning happens at the Gemba, not in a classroom.

What the SWCT Shows

The SWCT brings together the three elements of Standardized Work that define stability:

- Takt Time – The pace required to meet customer demand.

- Work Sequence – The defined order in which tasks are performed.

- Standard Work-In-Process – The minimum materials required to maintain flow without interruption.

Each element of the work is listed on the left side of the table. On the right, the graph shows how those tasks unfold in time. Manual work, machine time, and walk or wait time are plotted separately. The vertical takt line provides an immediate reference for stability. If any operation extends beyond that line, it exposes imbalance. If lines overlap or diverge, it shows where waste or unevenness is hiding.

This simple visual allows anyone, from operators to leaders, to see whether the process is balanced. The goal is not to reach a perfect pattern but to create a clear picture of reality that can be improved.

Why the SWCT Matters

Standardized Work exists to support people. The SWCT is the method that reveals how well that support is working.

At Toyota, leaders used the SWCT to confirm that every operator could perform the work safely, correctly, and within takt time. When instability appeared, it was addressed through structured Kaizen. In this way, the SWCT connected Standardized Work with leadership development.

Without the SWCT, imbalance hides inside averages. With it, problems become visible and improvement becomes logical. It turns assumptions into data and observations into facts. This visual confirmation builds shared understanding across the team. It also prevents firefighting, because leaders can see problems before they grow.

How to Read and Use the SWCT

The SWCT uses four types of information:

- Manual Work Time – Time the operator is directly engaged in performing a task.

- Machine Time – Time when equipment is running without direct operator involvement.

- Walk Time – Time used for movement between work locations or for part retrieval.

- Wait Time – Periods when neither the operator nor the machine is producing value.

By comparing these times to the takt reference, leaders can evaluate whether the process is synchronized with customer demand.

If the manual line crosses the takt line, the work is overloaded. If large gaps appear, capacity is underutilized. The SWCT does not judge; it shows. The discussion that follows is what creates learning.

At Toyota BT Raymond, this handwritten SWCT became a teaching tool. It was used in daily meetings to show how small changes in layout or sequence improved flow. When a new method was proven safer or more efficient, the table was updated. This is how standards evolve through Kaizen.

Learning from the Handwritten SWCT

The handwritten table demonstrates a key point in Lean TPS leadership development:

Standards are created at the process, by the people who perform the work.

Every number on the chart was collected through direct observation. Every note was written after confirmation at the Gemba. The process of writing, plotting, and analyzing created understanding. That understanding became the foundation for improvement.

This practice also reinforced Toyota’s leadership expectation: go and see for yourself.

Leaders who studied the SWCT learned to ask the right questions:

- Is the work sequence safe and repeatable?

- Does the operator have clear standards?

- Where does the process create waiting or walking?

- What small improvement could make the next cycle easier?

These questions guided learning and shaped the next generation of improvement leaders.

From Standardized Work to Continuous Improvement

The SWCT is not a technical form; it is a visual language for improvement. It connects Standardized Work, Kaizen, and leadership reflection into one system.

When a process is stable, Kaizen can take hold. When it is unstable, Kaizen must restore stability first. The SWCT provides the data to make that judgment.

At Toyota, this was part of daily management. Teams updated their SWCTs after every verified change. New leaders were trained to read and explain the chart before they were allowed to approve an improvement. This discipline prevented guesswork and built capability in every level of the organization.

Leadership Reflection

The handwritten SWCT remains one of the most effective teaching visuals in Lean TPS. It shows that improvement is not created by software or reports. It is created by structured observation and disciplined follow-up. When leaders learn to use the SWCT, they learn to see time as a design element of work.

That is what turns Standardized Work into a living system rather than a file in a binder.

Every improvement that holds begins with a standard.

The SWCT is the tool that defines that standard and connects it to leadership.