Too often, 5S is misunderstood as housekeeping. Boxes are moved, floors are swept, and signs are posted, but nothing really changes. True 5S Thinking builds a system of daily visual control and clear ownership. It creates environments where people think critically, act intentionally, and take pride in doing things the right way.

5S Is the Gateway to Lean TPS

In the Toyota Production System, the five steps of 5S: Sort (Seiri), Set in Order (Seiton), Shine (Seiso), Standardize (Seiketsu), and Sustain (Shitsuke), were never created for visual appeal. These practices enable flow, expose problems, and build reliable systems that eliminate waste and hidden cost.

At Toyota BT Raymond in Brantford, we applied Lean TPS 5S to reorganize tool cribs, receiving areas, and shipping zones. The Red Tag phase helped teams separate value from clutter. But lasting change came when we completed Standardize and Sustain. That was the turning point from project to system.

What Makes Lean TPS 5S Thinking Different

The Five Pillars of 5S Thinking in Lean TPS

Sort (Seiri) Remove what is not needed. At RW Tomlinson, we used Red Tag events to reclaim floor space, improve safety, and reduce response time.

Set in Order (Seiton) Create flow with clarity. At Toyota BT Raymond, we introduced labeled storage, quantity markers, and visual location cues to eliminate time wasted searching.

Shine (Seiso) Make cleaning purposeful. Shine uncovers defects and risk. Operators become inspectors and take pride in what they maintain.

Standardize (Seiketsu) Lock in improvements. We used checklists, visual schedules, and audits to keep improvements from slipping backward.

Sustain (Shitsuke) Make discipline a habit. Leaders coached teams until routines became second nature. 5S moved from instruction to culture.

From Kaizen to Jishuken: The True Progression

5S is the entry point to Kaizen, but it is not the endpoint. Once sustained, it becomes the base for long-term improvement cycles. The next level step change is Jishuken a structured, leader-involved initiative where operations and leadership behaviors align.

Jishuken is not an event. It is system-level problem solving rooted in daily performance, led by those who own the results. When 5S habits are strong, Kaizen gains traction. When Kaizen becomes the norm, Jishuken creates transformation.

This is why 5S must be more than a workshop. It must be taught, practiced, and reinforced by the people who live the system.

Real-World Impact

These are some of the results achieved across Lean TPS 5S projects:

• Inventory accuracy improved to 86.5 percent, saving $900,000 by reducing stockouts and part shortages • Shift consolidation from three shifts to one in key operations, reducing labor cost while protecting throughput • Visual management systems exposed equipment failures, shortages, and quality issues in real time • Kaizen and Jishuken readiness accelerated at sites that completed full 5S and reinforced Standardize and Sustain

These are not temporary results. They are structural. They reflect what happens when 5S is used as a thinking system, not a checklist.

Getting Started

If your organization is serious about Lean, 5S is the first system to master. It is not warm-up work. It is the starting point for the entire Toyota Production System.

I have implemented Lean TPS 5S Thinking across Takahama, Indiana, New York, Ontario, and North America. Each time, the sequence is the same. When leaders support 5S Thinking, the results last. The culture and the system both improve.

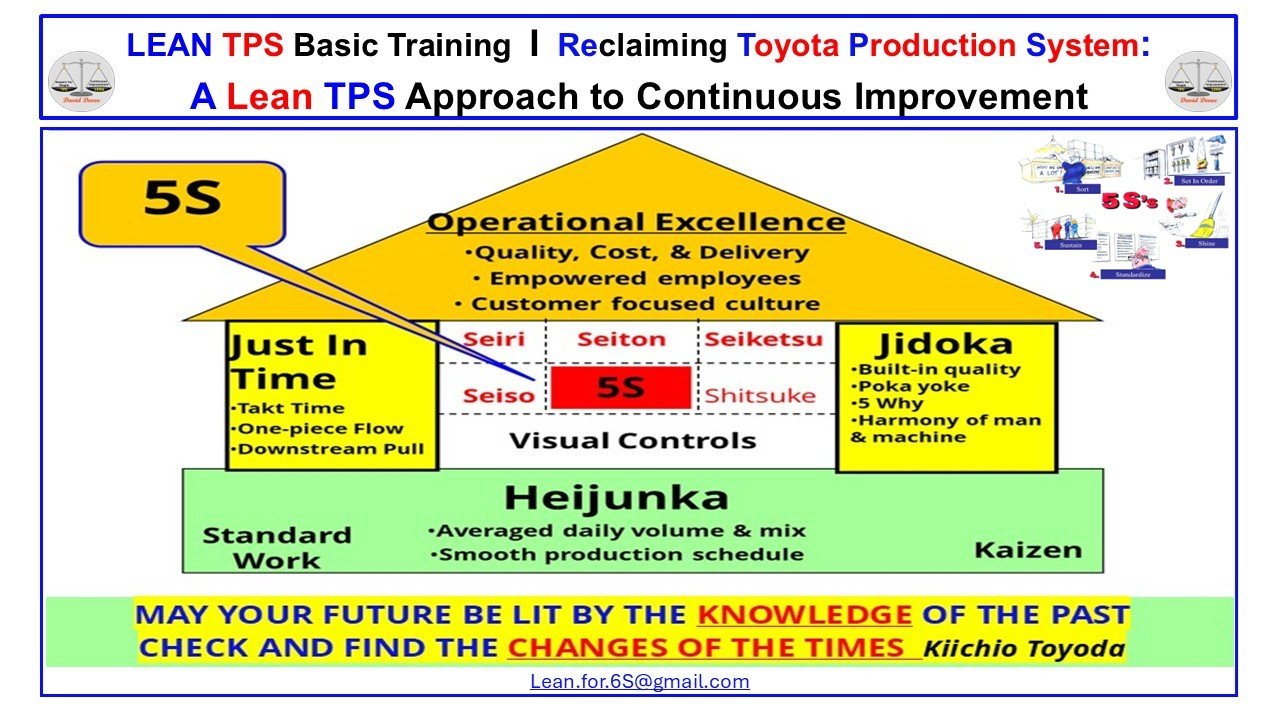

To support your journey, I have included the Lean TPS House visual. This image shows how 5S connects to Just In Time, Jidoka, and Heijunka. 5S is not what you do before Lean. It is Lean.

Let me know if you would like to explore how Lean TPS 5S Thinking can help your team build structure, remove fear, and create a workplace rooted in discipline and Respect for People.