Understanding Deviation, Standardization, and Continuous Improvement

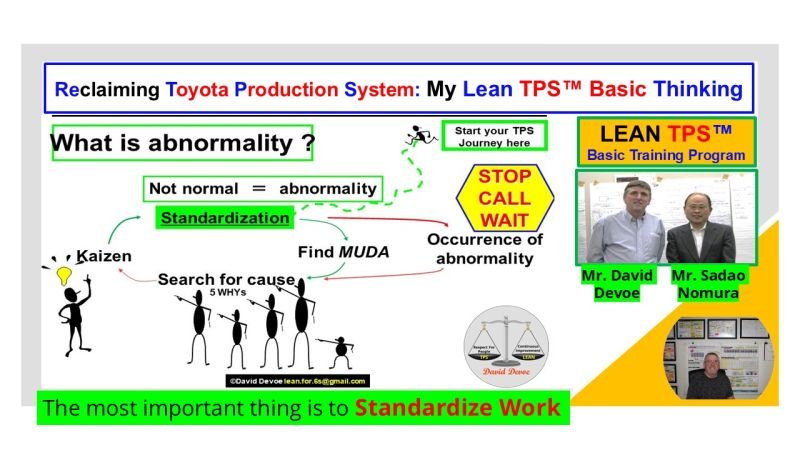

In Lean TPS, an abnormality is anything that deviates from the standard.

The phrase “Not normal equals abnormality” defines the foundation for all process improvement. Abnormalities are not problems to hide. They are signals that expose instability and opportunities for learning.

The Role of Standardization

Standardization is the first step in identifying and managing abnormalities. Without a clear standard, there can be no recognition of what is normal or abnormal.

Standardized Work defines the correct method, timing, and sequence of a task. It allows every operator and leader to detect deviation immediately and take action.

When the process is standardized, abnormalities become visible. When they are visible, they can be measured, analyzed, and improved.

The Stop–Call–Wait Process

When an abnormality occurs, the first responsibility is to stop the process. This action prevents defects from flowing downstream.

- Stop: Contain the abnormality immediately.

- Call: Notify the team leader or support personnel to assist in problem-solving.

- Wait: Resume only after the issue is understood and a countermeasure is confirmed.

This structured method creates a real-time response system that ensures immediate containment and initiates learning. It embodies the principle of Jidoka—built-in quality and respect for people through problem visibility and teamwork.

Finding Muda and Root Causes

Every abnormality is connected to some form of waste, or Muda. The purpose of Lean TPS is not only to fix symptoms but to uncover and eliminate these underlying wastes.

The seven forms of waste include:

- Overproduction

- Waiting

- Transportation

- Overprocessing

- Excess Inventory

- Motion

- Defects

To analyze an abnormality, the team applies the 5 Whys method to trace the cause-and-effect chain to its true source. This investigation builds understanding and prevents recurrence.

Kaizen: Turning Abnormalities into Improvement

Once the cause is identified, Kaizen methods are applied to design and test countermeasures. Kaizen transforms abnormalities into learning opportunities.

This continuous cycle strengthens stability and teaches everyone in the organization how to see problems, act on them, and sustain improvements.

Kaizen and Standardization work together.

- Kaizen eliminates waste and creates better standards.

- Standardization maintains the improvement and defines the new normal.

The Foundation of Lean TPS Thinking

The most important principle in Lean TPS is to Standardize Work. Without it, abnormalities remain hidden and improvement cannot be sustained.

Standardization provides:

- Clarity: Everyone understands the correct way to perform the job.

- Consistency: Work is repeatable and measurable.

- Control: Abnormalities are visible as soon as they occur.

- Capability: Continuous improvement becomes structured and teachable.

Abnormalities are not disruptions—they are valuable indicators that the system is working as intended by exposing problems. The goal of Lean TPS is not to eliminate abnormalities but to learn from them, strengthen processes, and build leadership capability.

Through Standardized Work, Stop–Call–Wait, and Kaizen, organizations can transform daily problem-solving into a disciplined system of improvement and learning.