In Lean TPS, leadership is not measured by control but by participation. The role of leadership in embedding continuous improvement begins with presence at the Gemba, the actual place where work is performed. True Lean TPS leadership is built through direct observation, structured reflection, and active learning alongside the people who create value.

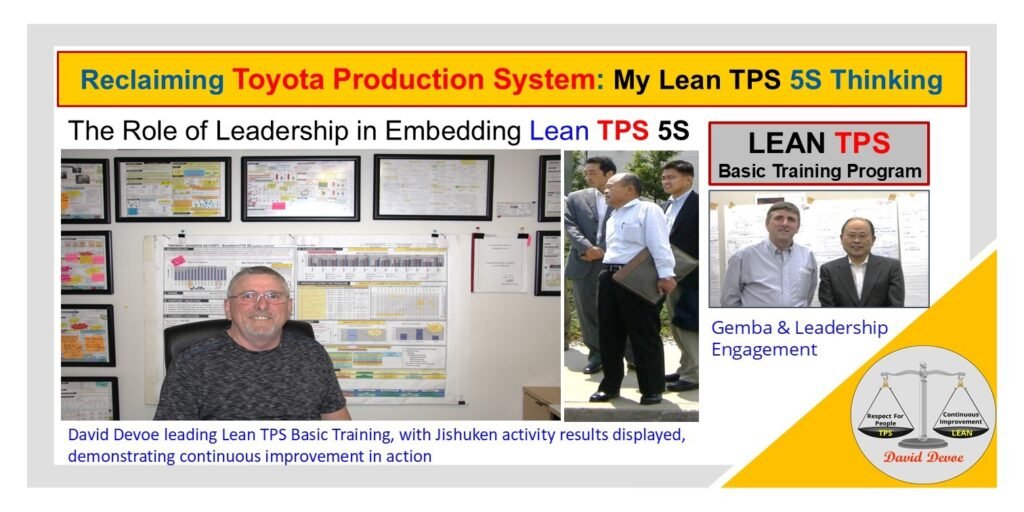

The image captures the essence of this practice. During Lean TPS Basic Training, Jishuken activity results are displayed openly, showing measurable progress achieved through teamwork and study. Leadership does not review these results from an office. They stand in front of them, ask questions, and guide improvement through dialogue.

At Toyota, leaders are developed by doing, not by managing from a distance. The responsibility of leadership is to teach and support problem solving. Each Jishuken activity provides an opportunity for leaders to strengthen their understanding of the system, test countermeasures, and reinforce discipline through Standardized Work. This approach turns leadership into a daily learning process.

Respect for People is at the center of this role. When leaders go to the Gemba, they demonstrate respect by taking time to see the challenges their teams face. They listen, observe, and work to remove obstacles that prevent smooth operation. This behavior builds trust and shows that continuous improvement is not a project but a shared responsibility.

In this environment, the Gemba becomes a classroom. Every visual chart, performance board, and standard reflects a learning opportunity. Leaders use these visuals to identify variation and confirm whether processes are stable. When problems are visible, they do not blame individuals but seek to understand the process. The question is always, “What condition allowed this to happen, and how can we prevent it?”

Leadership development through Lean TPS is also about modeling the discipline of Kaizen. When leaders participate directly in study groups, their actions set the tone for the organization. Improvement becomes part of daily management. The presence of senior leaders at Kaizen and Jishuken events signals that learning is valued as much as results.

This hands-on approach to leadership builds alignment across the organization. Everyone learns to think systematically, act on facts, and sustain improvements through Standardized Work. Over time, these practices create an organizational culture where leadership means service and responsibility, not authority.

By embedding continuous improvement into leadership behavior, Toyota ensures that Lean TPS is not dependent on programs or slogans. It becomes a living system of learning. The leader’s role is to make improvement possible, to teach problem solving, and to protect the culture that allows people to grow.