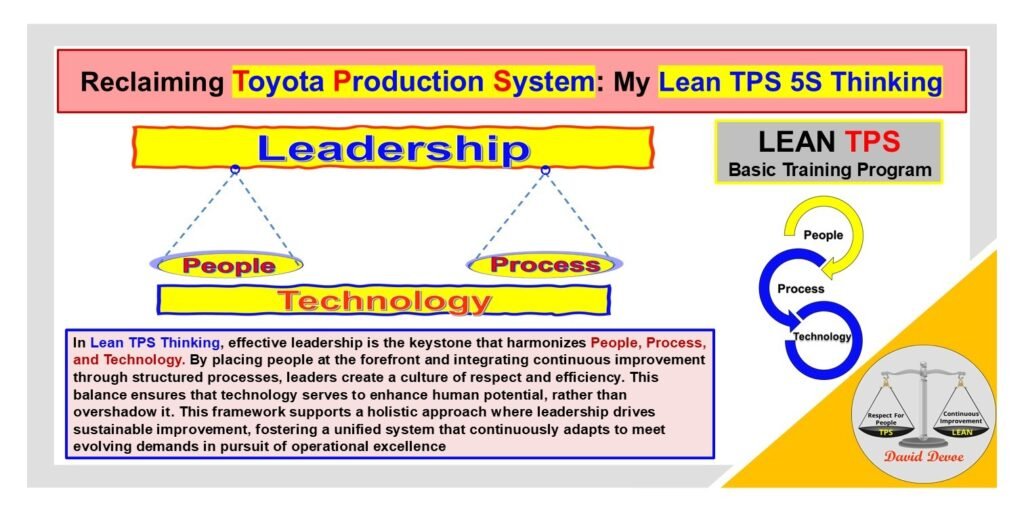

Leadership in Lean TPS is the balance point where people, process, and technology come together to create value. It is not about authority or control but about design and alignment. Effective leadership ensures that technology supports human capability, processes remain disciplined, and people are developed through structured improvement.

In the Toyota Production System, leadership begins with purpose. Leaders are expected to think long term, make decisions based on principle, and develop others through example. The foundation of every Lean TPS system is Respect for People and Continuous Improvement. Leadership connects these principles by building a workplace where people can succeed and learn through disciplined process and reliable systems.

This framework places people at the forefront. In Lean TPS, people are the system. Technology and process exist to support them, not replace them. Leaders create this balance by observing how work is performed, identifying barriers, and guiding teams toward better methods. When people understand the process and see the result of their improvement, motivation becomes natural and sustained.

Process forms the second element of this harmony. In Toyota, process stability is achieved through Standardized Work, visual controls, and problem-solving routines. Leaders ensure that every process has a clear purpose and repeatable method. When variation appears, they use tools such as PDCA and the 5 Whys to find and address root causes. By maintaining disciplined processes, leaders give their teams the structure needed for creativity and learning.

The third element is technology. Toyota applies technology carefully and only after the process and people are capable. The purpose of automation and digital tools is to support human judgment, not to replace it. Leaders evaluate technology based on whether it strengthens flow, improves safety, or enhances learning. When introduced properly, technology amplifies the benefits of a stable process and skilled people.

Together, these three elements form a triangle of harmony: People, Process, and Technology. Leadership sits at the top, maintaining balance among them. If leadership favors one side too heavily, the system becomes unstable. Too much focus on process can suppress creativity. Too much technology can reduce human skill. Too little structure leaves people without direction.

The role of the Lean TPS leader is to maintain this balance every day. They are teachers, coaches, and designers of systems that grow capability. By harmonizing people, process, and technology, they ensure that improvement is continuous, purposeful, and sustainable.

This alignment represents the essence of Lean TPS leadership: respect through balance, progress through learning, and excellence through disciplined practice.