The Andon communication system is one of the clearest examples of how Lean TPS connects people, process, and performance. It is not a display board for data. It is a living control system that links production activity to real-time decision making, ensuring that flow, quality, and teamwork remain visible and aligned with the daily plan.

At Toyota BT Raymond, the Andon board is the pulse of production. Every number, color, and signal represents the current condition of the line. It shows how many units have been completed, how many remain, and how much time is available to achieve the target. This visibility transforms management from supervision to support. Problems are no longer hidden within reports; they are seen, discussed, and acted upon immediately.

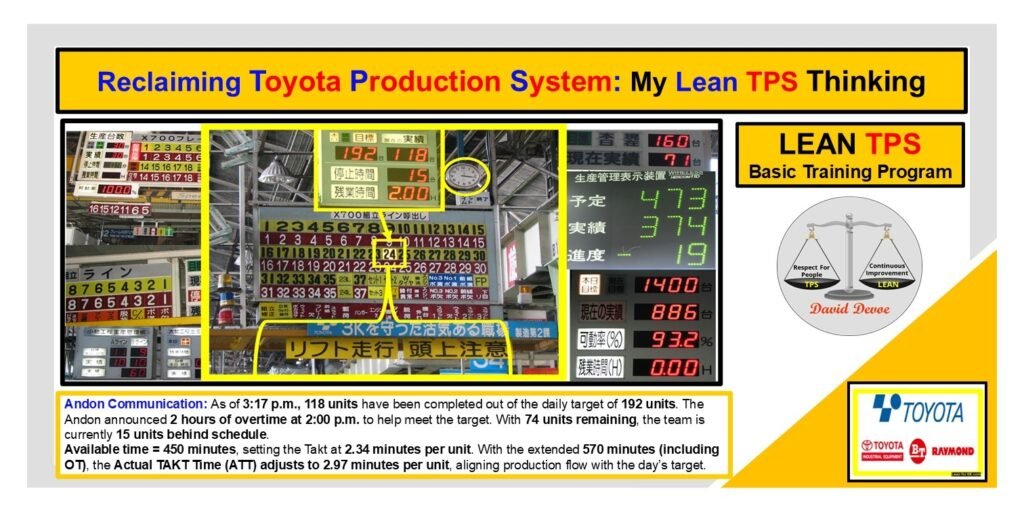

In this example, the Andon communication board displays a clear summary of performance. As of 3:17 p.m., 118 units have been completed out of the daily target of 192. The Andon system announced two hours of overtime at 2:00 p.m. to help meet the target. With 74 units remaining, the team is 15 units behind schedule. Available time equals 450 minutes, setting the Takt at 2.34 minutes per unit. With the extended 570 minutes including overtime, the actual Takt Time adjusts to 2.97 minutes per unit. This simple calculation aligns the team with the new daily rhythm.

The purpose of Andon communication is to make abnormality visible. It tells the truth about the situation in real time so the team can respond. When production is behind, the cause is investigated immediately. Leaders ask what is preventing flow and what countermeasure is needed. When production is ahead, the discussion shifts to stability and improvement.

Andon also strengthens respect for people. Instead of waiting for instructions, operators and team leaders take ownership of their area. They can call attention to problems as they occur. This open communication prevents blame and promotes teamwork. Each signal, whether a light, number, or sound, represents a request for help.

The daily routine of reviewing Andon performance builds discipline. It reinforces how Lean TPS operates as a system of learning. Every fluctuation in pace or quality becomes a learning opportunity for the team. The board is not there to monitor individuals; it is there to reveal the system’s behavior and support improvement.

By connecting data, people, and action, Andon communication keeps production aligned with customer demand while maintaining quality. It teaches that information must flow just as smoothly as material. When used correctly, Andon turns management into a real-time coaching system where problems are visible, countermeasures are tested, and performance becomes predictable.

This approach represents the essence of Lean TPS: stability through visibility, leadership through support, and improvement through participation.