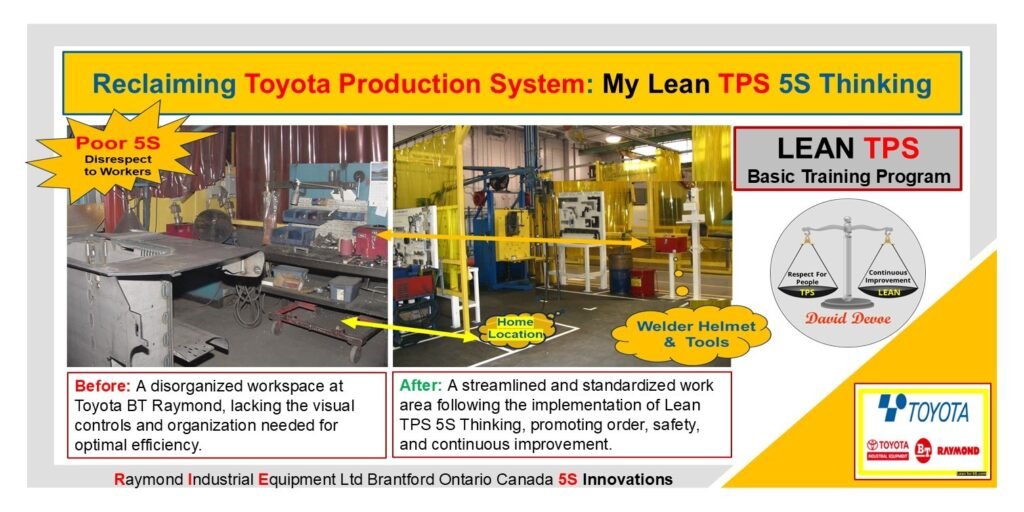

At Toyota BT Raymond in Brantford, the weld cell transformation became a defining example of Lean TPS 5S Thinking in action. What began as a cluttered, unsafe, and inefficient workspace was rebuilt into a model area for quality, safety, and continuous improvement. This transformation did not come from technology or investment. It came from structure and discipline.

Before the change, the weld cell represented many of the problems Toyota identifies as waste. Tools were scattered across benches, weld helmets had no designated home, and visual controls were almost nonexistent. Operators spent time searching for equipment instead of adding value. Dust and debris covered surfaces, hiding potential safety issues and defects. This was not simply poor housekeeping. It was a sign of system failure and disrespect for workers.

Lean TPS 5S Thinking changed that. By applying the five foundational steps—Sort, Set in Order, Shine, Standardize, and Sustain—the team created a visual and functional workplace that supported both safety and quality. Every tool gained a defined location. Pathways were marked to ensure clear movement. Equipment was positioned according to workflow, not convenience.

The improvement began with Sort. Everything unnecessary was removed, exposing the true scope of the problem. Set in Order followed, establishing home locations for all essential items. Tools, helmets, and materials were placed where they were needed most, eliminating wasted motion and confusion. Shine made cleaning a daily inspection process, ensuring that every surface and machine was checked for abnormalities.

Once the area was stable, Standardize captured the best practices through clear visuals and defined routines. The team developed a standard method for maintaining the area, supported by checklists and 5S evaluations. Sustain came last, embedding these standards into the team’s daily rhythm. Leaders reinforced the new habits through regular audits, coaching, and daily reflection meetings.

The result was not only a cleaner weld cell but also a safer and more productive environment. Operators took ownership of their area, understanding that maintaining order was part of their role in building quality products. Safety hazards were eliminated. Work could be done faster and with greater confidence.

Most importantly, the transformation showed that 5S Thinking is an act of respect. By creating a structured, safe, and efficient workplace, leadership demonstrated care for the people who perform the work. When employees see that their environment supports their success, engagement and improvement follow naturally.

This weld cell project proved that Lean TPS 5S Thinking is not cosmetic. It is the starting point for building flow, standardization, and continuous improvement. The system’s power lies in its simplicity and its ability to make waste visible. When every tool, surface, and standard communicates purpose and respect, the workplace becomes a living example of Toyota’s principle: “Build quality into the process.”