In the early development of the Toyota Production System, before the full structure of 5S was established, Toyota engineers focused on two foundational steps: Sort and Set in Order. This was known as 2S Thinking. Its purpose was simple but powerful—create a workplace where waste could not hide.

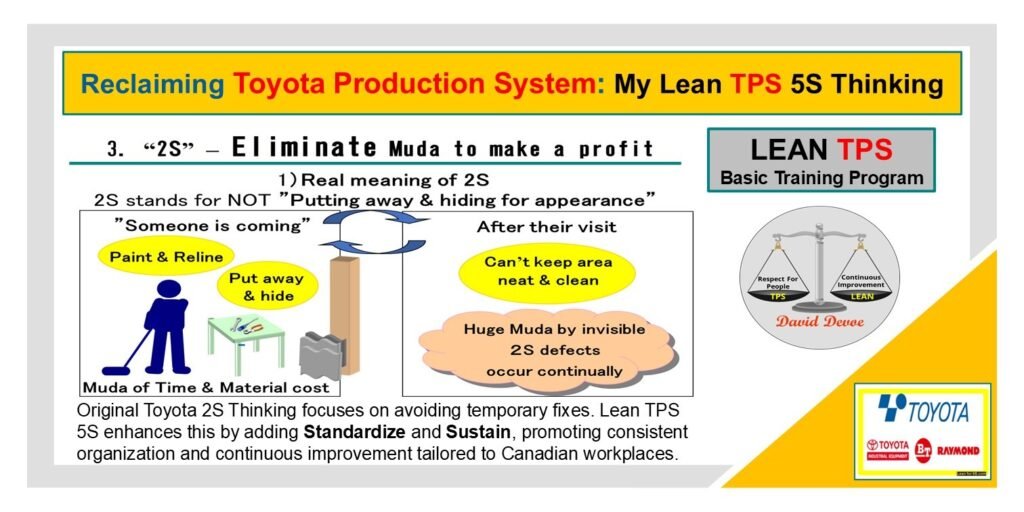

Mr. Sadao Nomura, one of Toyota’s leading quality experts, often emphasized that 2S was not about tidying up for appearance. It was about discipline, awareness, and the elimination of hidden waste. When people clean only because “someone is coming,” they remove the symptom, not the cause. The result is temporary improvement followed by a return to disorder.

The real meaning of 2S lies in its ability to expose abnormalities. By removing what is unnecessary and putting everything in its proper place, the workplace becomes a visual system where problems are immediately visible. This visibility is what makes 2S the foundation of Lean TPS.

Toyota’s early production floors in Takahama and Kariya applied 2S daily to uncover defects, wasted motion, and misplaced inventory. The focus was not cosmetic. The goal was to eliminate Muda—the waste of time, material, and energy caused by disorganization. By teaching workers to see what did not belong and to maintain order, Toyota created the basis for continuous improvement.

However, 2S alone was not enough. Without structure to maintain the gains, problems reappeared. Over time, Toyota expanded 2S into 5S by adding Shine, Standardize, and Sustain. These additional steps provided the framework to make improvement continuous and self-reinforcing.

At its core, 2S Thinking teaches that efficiency and profit come from eliminating the causes of waste, not hiding them. It rejects the habit of painting over or storing clutter just to look good for a visitor. True improvement requires uncovering the root of inefficiency and redesigning the system to prevent its return.

In modern workplaces, 2S still holds value as the first practical step toward Lean TPS maturity. When applied correctly, it builds awareness and ownership. When combined with Standardize and Sustain, it becomes a stable management system that promotes reliability, safety, and respect for people.

In Canada and North America, the challenge is the same as it was in early Toyota plants: avoiding temporary fixes and embedding habits that last. Lean TPS 2S Thinking provides a visual and behavioral structure for this. It transforms cleaning from an activity into an inspection and turns organization into a daily reflection of discipline.

Eliminating Muda is not a one-time project. It is the ongoing pursuit of perfection that begins with 2S Thinking.