A Lean TPS Basic Training Article

By David Devoe

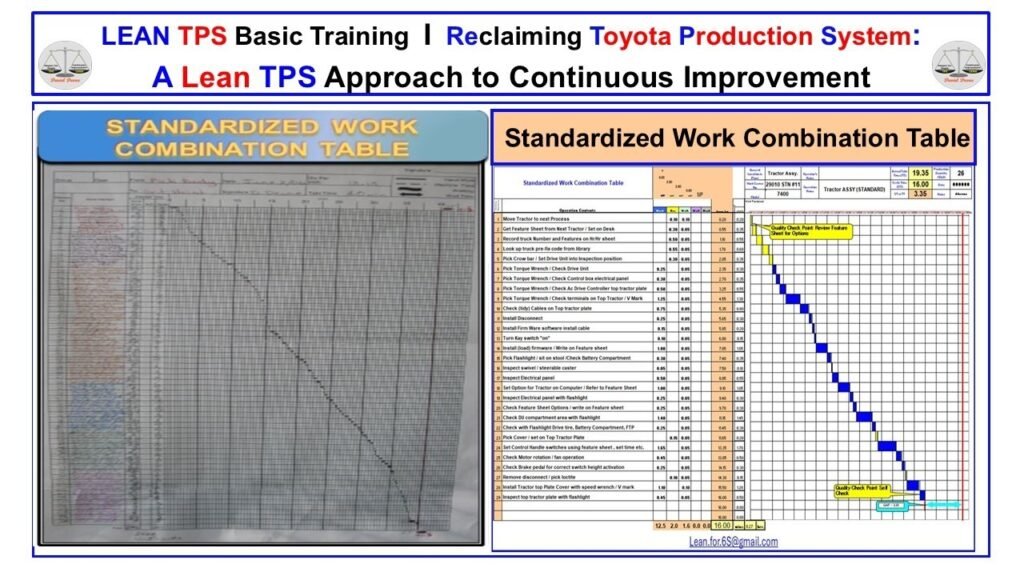

At Toyota Industries Corporation in Takahama, I learned that Standardized Work is not a set of documents. It is a structured discipline that defines how people, machines, and materials interact in time and sequence to create stability. The Standardized Work Combination Table (SWCT) is the visual tool that makes this relationship clear. It shows where flow is supported and where instability exists. This table is one of the most practical instruments of Lean TPS because it connects the thinking of leaders to the reality of daily work.

What the SWCT Represents

The Standardized Work Combination Table brings together three fundamental elements of Standardized Work: takt time, work sequence, and standard work-in-process. It translates these elements into a chart that shows the relationship between manual time, machine time, and walking or waiting time. Every second of an operator’s cycle is accounted for. By plotting this data visually, waste becomes obvious and opportunities for Kaizen can be seen by everyone.

In a typical Toyota operation, the SWCT is used to display how the operator’s manual work aligns with the takt time required to meet customer demand. The left side of the table lists every step in the work sequence. The right side shows a graph that layers manual and machine operations over time. When these lines overlap or extend beyond takt, leaders can see where the process is overloaded or under-utilized. The goal is to create a rhythm where people and machines work together in a balanced flow.

The SWCT also forms the connection point between Standardized Work and Kaizen. It provides the baseline for measuring improvement. Without it, problems are hidden in averages and assumptions. With it, every improvement is visible, measurable, and repeatable.

Why the SWCT Is Essential

The SWCT is more than a time study chart. It is a visual representation of process stability. It answers critical leadership questions:

- Is the operator’s work balanced to takt time?

- Are there overlapping operations or idle machines?

- Are safety checks and quality verifications built into the cycle?

- Is the process repeatable and teachable?

At Toyota, leaders do not evaluate efficiency in isolation. They confirm whether the Standardized Work sequence can be safely repeated and improved. The SWCT provides that confirmation. It ensures that the process is stable before improvement is attempted.

When used correctly, the SWCT becomes a communication tool between operators, engineers, and supervisors. It aligns everyone on the same facts and exposes variation before it causes quality or safety issues. The chart does not replace observation. It strengthens it by providing a structured lens through which to see.

How to Create an SWCT

Creating a Standardized Work Combination Table requires real observation and accurate data collection. The steps below reflect the Toyota approach used in Lean TPS Basic Training:

- Define Takt Time

Calculate the time available to meet customer demand. Takt is the heartbeat of the process and the reference for balance. - Observe the Work Sequence

Go to the Gemba and record each task performed by the operator, including walk, manual, and machine time.

Separate value-added work from non-value-added actions. - Record Times by Element

Measure manual handling time, machine processing time, and any waiting or walking between stations. - Plot the Sequence on the SWCT

The vertical axis lists each work element. The horizontal axis represents time. Use different line types for manual, machine, and walk time.

Example:- Solid line = Manual work

- Dashed line = Machine time

- Dotted line = Walk or wait

- Mark the Takt Line

Draw a vertical reference line at the takt time position. This line allows immediate visual comparison between work content and available time. - Analyze Balance and Overlap

Look for sections where the manual time extends past the takt line, where machines idle, or where operators wait unnecessarily. These are improvement opportunities. - Confirm with the Operator

Review the chart at the Gemba with the person performing the work. Confirm the accuracy of each element and discuss what could be improved. - Implement Kaizen and Revise the SWCT

Test changes that reduce waste, rebalance work, or improve safety. Update the SWCT to reflect the new standard.

Standardized Work must evolve as better methods are proven.

Example from Toyota Operations

During training at Toyota Industries, we studied how the SWCT stabilized assembly operations on mixed-model lines. Each operator had a sequence of manual assembly tasks supported by machines that tightened bolts, performed inspections, and verified safety points. Without visualization, it was difficult to see how machine cycles affected operator balance. By plotting the data on the SWCT, variation became visible within minutes.

One example involved a tractor assembly line. The SWCT showed that one operator’s manual work exceeded takt time by 0.5 seconds, while another operator had idle time between machine cycles. By slightly redistributing tasks and adjusting machine timers, the line became balanced. The improvement was small, but the impact was significant. Through visualization, the team removed frustration, reduced waiting, and improved rhythm.

At Toyota BT Raymond in Canada, the same logic applied in warehouse assembly. The SWCT helped reveal that two manual tasks overlapped during equipment test operations. This overlap created congestion and wasted motion. By sequencing these steps differently, safety improved and takt balance was restored. The SWCT became the visual proof of improvement.

Integration with Other Standardized Work Tools

The SWCT works in combination with two other documents:

- Standardized Work Chart (SWC):

A top-down view showing operator paths, part locations, and machine positions. It makes motion waste visible. - Standard Work Element Sheet (SWES):

A detailed breakdown of each element, showing time, safety, and quality checks.

Together, the SWC, SWCT, and SWES form the foundation of Lean TPS Standardized Work. They create the shared understanding needed for teamwork and training. The SWCT adds the time dimension that ties everything together.

The Leadership Function of SWCT

For Toyota leaders, the SWCT is not only a technical tool. It is a leadership instrument. Supervisors use it to teach Standardized Work, confirm balance, and guide problem-solving. During daily management or Jishuken activities, leaders review SWCTs with their teams to ask simple but critical questions:

- Is the sequence still being followed?

- Has any step changed without confirmation?

- Are the improvement effects sustained?

This dialogue forms the basis of Genchi Genbutsu — going and seeing the real situation. When the SWCT is posted and discussed daily, the workplace becomes self-learning. Operators can explain their work visually, and leaders can coach improvement based on fact.

At Toyota BT Raymond, the leadership team used SWCTs as part of Asaichi (morning meetings). Each day, they reviewed one process with the team. Any imbalance, safety concern, or idea for Kaizen was noted and assigned. This built a culture of disciplined reflection rather than reactive firefighting.

Common Pitfalls and Countermeasures

While the SWCT is a powerful visual, its effectiveness depends on correct use. These are common pitfalls and countermeasures observed in practice:

| Pitfall | Countermeasure |

|---|---|

| Treating the SWCT as paperwork | Conduct the study at the Gemba and confirm with operators. |

| Using rough time estimates | Use stopwatch or video analysis to capture accurate data. |

| Not updating after Kaizen | Revise the SWCT immediately when improvements are verified. |

| Focusing only on time reduction | Confirm safety, ergonomics, and quality first. |

| Ignoring leader involvement | Use SWCTs as part of leader standard work and coaching. |

The SWCT must never be created from assumptions or memory. Its strength lies in its accuracy and visibility. When kept current, it becomes a living document that supports both people and performance.

The Link Between Standardized Work and Kaizen

Standardized Work defines the current best method. Kaizen improves it. The SWCT is the bridge between the two. It stabilizes work so that improvement can hold. Without Standardized Work, Kaizen fades. Without Kaizen, Standardized Work becomes obsolete.

At Toyota, every improvement was validated through Standardized Work documents. Once a new method was confirmed to improve safety, quality, or productivity, the SWCT was updated, and training followed immediately. This cycle ensured that improvement never depended on individuals alone. It became systemized learning.

This is why Toyota considered Standardized Work the backbone of Lean TPS. It connected people’s ideas to the system’s performance. Every operator, team leader, and engineer spoke a common language defined by takt time, sequence, and flow.

The 9-Step Method for Sustainable Standardized Work

In Lean TPS Basic Training, the 9-Step Method ensures that Standardized Work becomes part of daily practice rather than a one-time activity:

- Define the work purpose and boundaries.

- Capture the current sequence of steps.

- Measure cycle times accurately.

- Calculate takt time from demand and shift time.

- Build the Standard Work Element Sheet.

- Create the Standardized Work Combination Table.

- Confirm with operators and adjust for safety and flow.

- Train all members to the standard.

- Audit and improve through Kaizen and Yokoten.

Following this sequence creates structure, consistency, and shared understanding. It turns improvement into a scientific process instead of opinion-based debate.

My Reflection on Learning SWCT

The first time I learned to build an SWCT at Toyota Industries, I realized how it transforms invisible problems into visible ones. It was not a form to complete but a way of thinking. The act of writing each element, plotting each second, and comparing to takt revealed how tightly interconnected people and processes are. When we respect that structure, improvement becomes natural.

The lesson was simple: you cannot improve what you cannot see. The SWCT gives you the ability to see.

When I later applied this at Toyota BT Raymond, the tool became a daily management habit. Teams posted their SWCTs near the work area. Leaders used them to coach, confirm standards, and recognize improvement ideas. The result was stability and engagement. People saw their own contribution to the flow.

The SWCT in the Lean TPS Swiss Cheese Model

In the Lean TPS Swiss Cheese Model, Standardized Work is one of the structural layers that prevents failure. The SWCT acts as the “visual proof” layer. It identifies holes in the process before they align to create breakdowns. When leaders monitor these charts, they can act on risk early rather than react to results later.

This predictive function makes the SWCT a prevention tool as much as an improvement tool. It strengthens the foundation of Lean TPS by creating visibility that supports both people and performance.

Conclusion: A Visual Discipline for Stability and Growth

The Standardized Work Combination Table represents more than a chart. It is a visual expression of the Toyota philosophy. It captures the precise relationship between people, machines, and time. It connects Standardized Work to leadership, Kaizen, and learning.

When organizations struggle to sustain improvement, the missing element is often Standardized Work. Without a stable standard, every improvement fades. The SWCT restores structure and creates the foundation where people can think and improve together.

The goal of Lean TPS Basic Training is not to fill templates but to build capability. The SWCT supports that goal by teaching how to see. Once you can see, you can improve.