Reclaiming Toyota Production System: My Lean TPS Basic Thinking

Lists that group TPS, Lean, Six Sigma, and Kaizen together often confuse history and misrepresent purpose. While all contributed to improvement, they differ in philosophy, structure, and intent. The Toyota Production System stands apart as a complete management system built on problem-solving and respect for people, not a collection of tools.

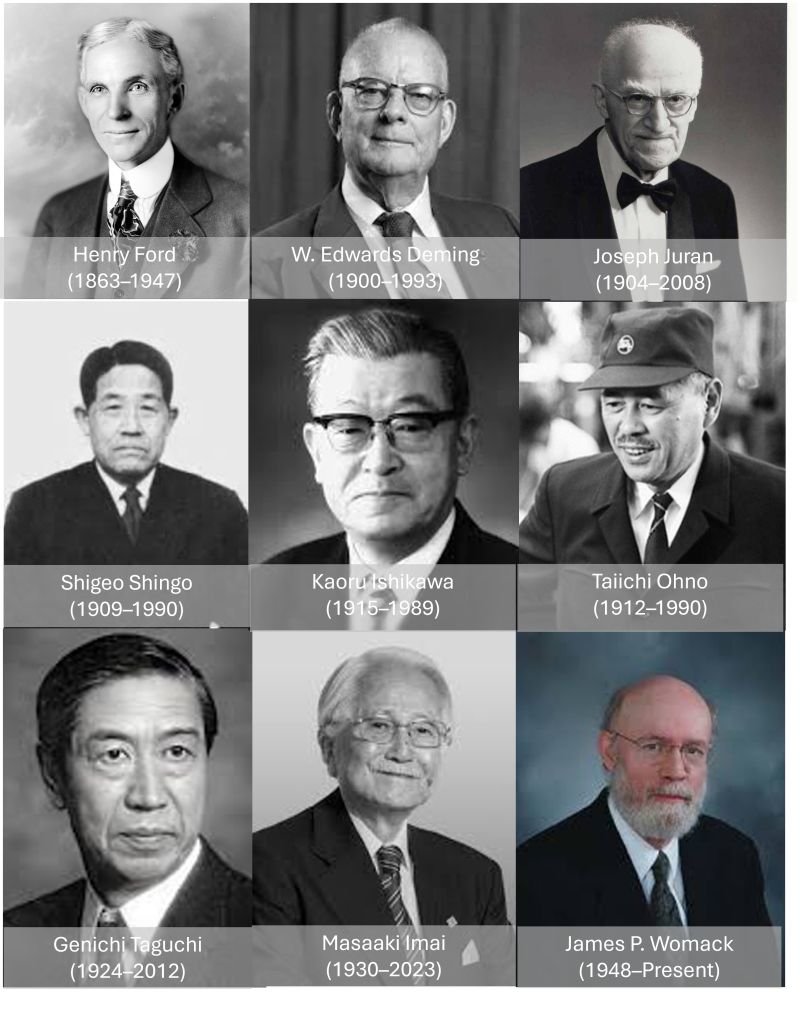

To preserve accuracy, it is essential to distinguish pioneers, architects, and practitioners. This classification clarifies who created new systems, who structured them, and who promoted or applied them.

Misclassification of Figures

Many improvement leaders are incorrectly labeled as “gurus.” The term blurs their true roles and contributions.

Pioneers introduced original concepts that changed industrial practice.

Architects structured methods and principles into systems.

Practitioners applied and spread these systems through teaching, documentation, or consulting.

Recognizing these roles provides a more accurate understanding of the evolution of improvement.

Correct Historical Context

Lean did not exist before 1988.

The term “Lean” was introduced in The Machine That Changed the World to describe elements of the Toyota Production System observed externally. Lean borrows TPS tools but often omits its cultural and quality foundations. TPS existed decades earlier as a complete system built on Just-in-Time, Jidoka, and people development.

TPS must be recognized as the origin.

Toyota’s system transformed manufacturing by creating flow, eliminating waste, and embedding quality at the source. Lean simplifies this depth, often reducing it to efficiency tools rather than a leadership system.

Six Sigma is separate.

Developed and commercialized by GE, Six Sigma relies on statistical control and the unproven 1.5 sigma shift assumption. Its focus on defects differs from TPS, which targets waste, variation, and imbalance through process design and prevention.

Kaizen is not generic.

Kaizen is a registered trademark of the Kaizen Institute. It represents a structured approach to continuous improvement and should not be generalized or detached from its original meaning.

Reevaluating the Key Figures

Each figure in the commonly shared list deserves correct attribution:

| Name | Contribution Type | Key Contributions |

|---|---|---|

| Henry Ford | Pioneer, Architect | Flow production, standardization, and early assembly line development. |

| W. Edwards Deming | Architect | Statistical Process Control, PDCA, and management principles for quality. |

| Joseph Juran | Architect, Practitioner | Juran Trilogy, Pareto analysis, and quality leadership. |

| Kaoru Ishikawa | Architect, Practitioner | Total Quality Management, Fishbone Diagram, and Quality Circles. |

| Taiichi Ohno | Pioneer, Architect, Practitioner | Toyota Production System, Just-in-Time, Kanban, and waste elimination. |

| Shigeo Shingo | Pioneer, Practitioner | Poka-Yoke, SMED, and process efficiency. |

| Genichi Taguchi | Architect, Practitioner | Robust design, Loss Function, and quality engineering. |

| Masaaki Imai | Practitioner | Promoted and globalized Kaizen philosophy. |

| James P. Womack | Practitioner | Documented and explained TPS through “Lean” research but did not create it. |

The Overlooked Foundation: Quality

Quality is the core of TPS. The system’s strength lies in prevention, not inspection. By integrating quality into every step, TPS eliminates cost and risk before they reach the customer. Deming, Juran, Ishikawa, and Taguchi contributed essential foundations for this mindset.

Any classification that neglects quality as the center of improvement misrepresents what Toyota built. Improvement without built-in quality cannot be sustained.

The True Gurus

If one individual deserves recognition as a true TPS guru, it is Taiichi Ohno. He did not write theory from observation; he developed the system through direct experience at the shop floor. His thinking connected leadership, quality, and daily improvement into one living structure.

Equally important, Sakichi Toyoda and Kiichiro Toyoda must be included in any true account of TPS origins. They were pioneers and architects whose invention, discipline, and purpose created the foundation for Toyota’s continuous pursuit of excellence.

Preserving the Integrity of TPS

Mislabeling these figures erases the distinction between systems. TPS should not be grouped with Lean or Six Sigma. It stands as a system of leadership that develops people to prevent failure and achieve perfection through process design.

To reclaim TPS, we must preserve its history, terminology, and intent. The goal is not to combine systems but to understand and apply them with integrity.