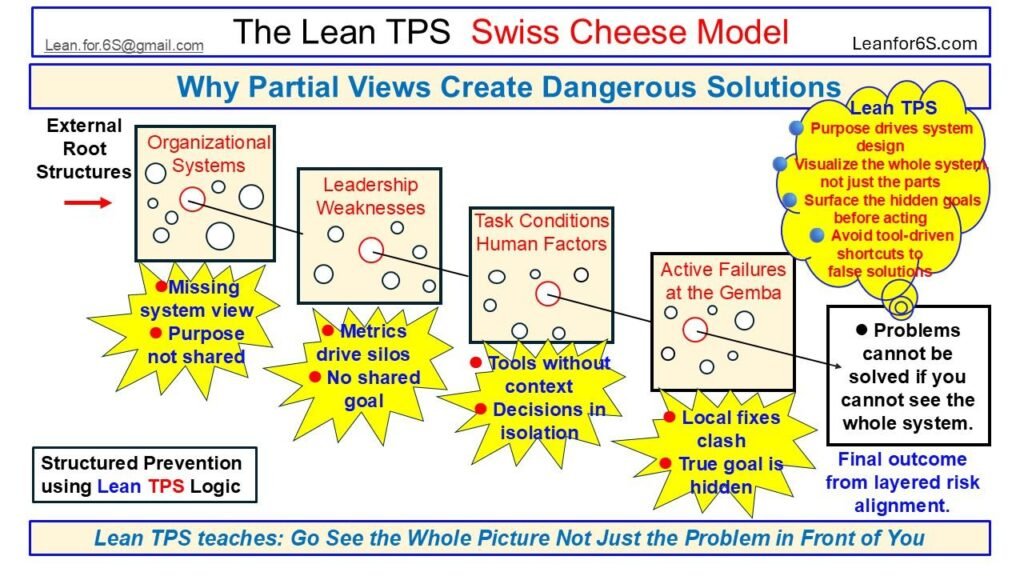

Most organizations believe their biggest risks come from visible problems. In Lean TPS, the real danger comes from what is not seen. It is the hidden connections between people, processes, and leadership that quietly align into failure.

The Lean TPS Swiss Cheese Model explains this clearly. Problems are rarely caused by single events. They are the result of layered risks that silently line up across time, departments, and decisions. Each layer seems small and unrelated, but when they align, they allow a complete system failure to pass through every barrier.

When the system view is missing, teams act locally. They make fixes that appear logical in isolation but collide when viewed together. Leadership focuses on metrics instead of shared purpose. Task conditions change without full context. Frontline operators adapt, creating workarounds to survive immediate pressures. Each layer performs its best, but none can see the whole picture.

The result is not individual failure. It is system failure.

This is why Toyota built Lean TPS as a prevention system, not a reaction system. The goal is not to close every hole separately but to align the structure so that the holes never line up. When alignment exists, the system becomes capable of absorbing variation without breaking. When it does not, the same problems return in different forms.

During my TPS Basic Training at Toyota L&F Takahama, this concept was reinforced through daily problem solving. When a line stopped, the question was never “who made the mistake.” The question was “what part of the system allowed this condition to exist.” That reflection connected production, maintenance, logistics, engineering, and leadership. Each function had to study how its design influenced the next.

This is the discipline of structured prevention. Standardized Work defines how the process should run. Visual Management makes abnormality visible. Jidoka ensures problems stop before they spread. PDCA turns every incident into learning. Leadership aligns purpose so that every improvement fits within a shared goal.

When this alignment exists, small gaps are offset by strong systems. When it does not, risk passes through every layer.

The Lean TPS Swiss Cheese Model is not about fear of failure. It is about respect for system design. It reminds us that improvement without structure hides problems deeper. True prevention comes from seeing the system as one connected body, where every decision either strengthens or weakens alignment.

Problems cannot be solved if you cannot see the whole system. Lean TPS teaches us to go and see, clarify the purpose, and build prevention into the work itself.