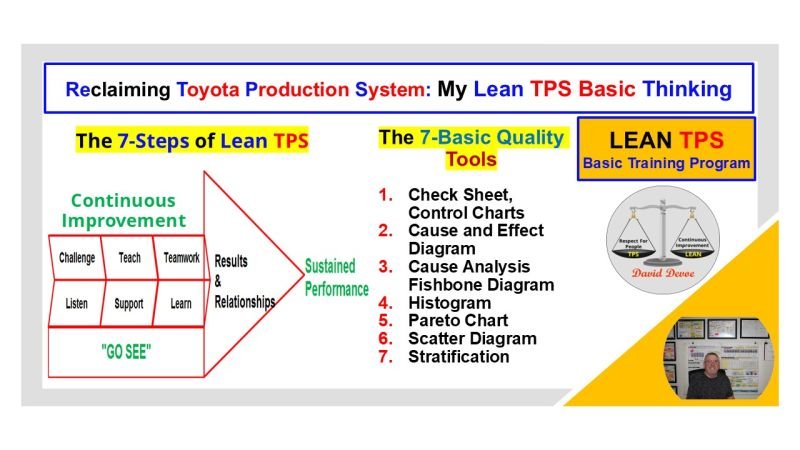

Sustainable improvement requires structure. In Lean TPS, quality and continuous improvement depend on two interconnected systems: The 7 Basic Quality Tools and The 7 Steps of Lean TPS. Together, they form a disciplined framework for achieving stable processes, preventing waste, and developing people.

The 7 Basic Quality Tools: The Foundation of Process Excellence

The 7 Basic Quality Tools provide the technical structure for identifying, analyzing, and eliminating defects before they reach the customer. Each tool supports fact-based decision-making and ensures problems are addressed at the root cause.

- Check Sheet and Control Chart – Capture real-time data to identify patterns and trends.

- Cause and Effect Diagram – Clarify relationships between potential causes and observed problems.

- Cause Analysis Fishbone Diagram – Visualize contributing factors across people, machines, materials, and methods.

- Histogram – Display variation in process results to assess stability.

- Pareto Chart – Apply the 80/20 rule to focus on the most significant causes of defects.

- Scatter Diagram – Reveal correlations between variables influencing process performance.

- Stratification – Separate and classify data to identify sources of variation.

When applied correctly, these tools prevent firefighting by making problems visible, measurable, and actionable. They create the conditions for built-in quality, or Jidoka, by ensuring every defect is both detected and understood before countermeasures are applied.

The 7 Steps of Lean TPS: Embedding Continuous Improvement

While quality tools provide data and analysis, the 7 Steps of Lean TPS define how improvement becomes part of the culture. These steps guide leaders and teams through the daily discipline of improvement.

- Challenge – Approach problems with curiosity and persistence.

- Teach – Share knowledge and build capability in others.

- Teamwork – Engage cross-functional collaboration to achieve shared goals.

- Listen – Understand the perspectives of those closest to the work.

- Support – Provide resources and reinforcement to sustain results.

- Learn – Reflect on successes and failures to strengthen problem-solving.

- Go See (Genchi Genbutsu) – Observe processes directly to confirm facts and conditions.

These steps transform improvement from an event into a behavior. They connect leadership with the shop floor and link continuous improvement to Respect for People—a defining principle of the Toyota Production System.

Integrating Tools and Thinking

In Lean TPS, the 7 Quality Tools and 7 Steps of Lean Thinking are never separate. Tools structure the analysis. Thinking sustains the improvement. When both operate together, the system becomes self-reinforcing.

- Tools make abnormalities visible.

- Leadership ensures those abnormalities are acted upon.

- Continuous reflection strengthens both process and people.

This integration builds organizational capability. It ensures that improvement is not dependent on a few individuals but embedded in how the organization operates.

Final Reflection

The success of any Lean initiative depends on the balance between structured tools and disciplined thinking. Toyota achieved lasting excellence because it built systems that teach people how to see, think, and act.

Lean TPS applies that same principle. The combination of the 7 Basic Quality Tools and the 7 Steps of Lean Thinking creates a system that sees problems clearly, solves them systematically, and sustains results through leadership and learning.