Operational excellence begins with structure. In Lean TPS, success depends on the ability to visualize, prevent, and sustain improvements through disciplined use of quality tools. Improvement is not achieved by isolated projects but by integrating these tools into daily work.

Toyota built its strength on structured problem-solving, where process clarity and defect prevention form the basis for continuous improvement. The Lean TPS Basic Training Program introduces three powerful tools that define this foundation.

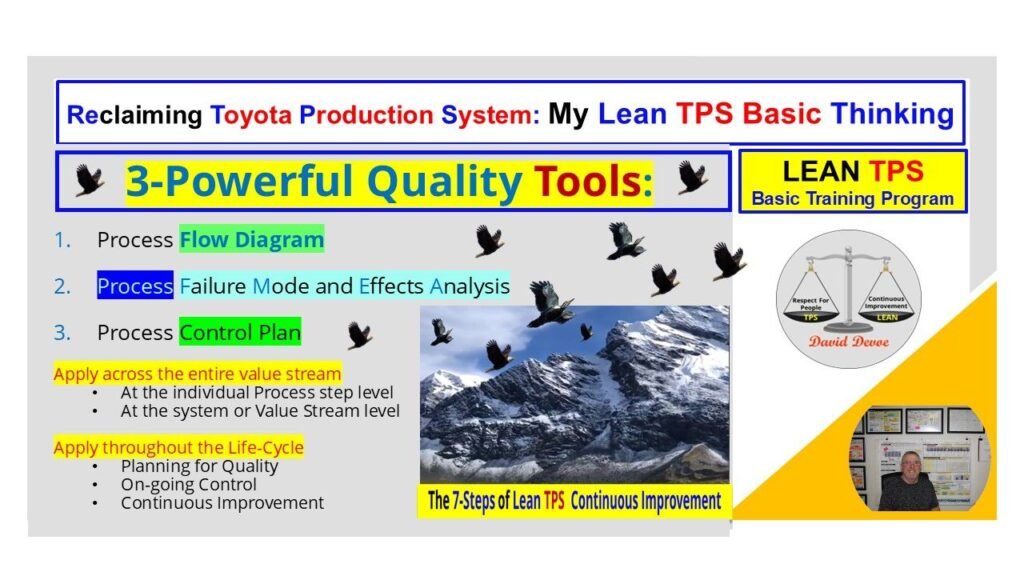

The 3 Powerful Quality Tools in Lean TPS

1. Process Flow Diagram

A Process Flow Diagram visually maps the sequence of work, material, and information movement within a process. It reveals how work truly flows and where value is lost.

- Identifies bottlenecks, waiting time, and unnecessary motion.

- Establishes a shared understanding of process structure.

- Forms the baseline for Kaizen by making waste visible.

The Process Flow Diagram is the first step toward standardization because it exposes hidden complexity and provides the factual basis for improvement.

2. Process Failure Mode and Effects Analysis (Process FMEA)

Preventing defects starts with understanding potential failures before they occur. Process FMEA analyzes how and where a process might fail and establishes countermeasures to prevent recurrence.

- Identifies and ranks risks by severity, occurrence, and detection.

- Builds defect prevention into the process rather than relying on inspection.

- Reinforces Jidoka, ensuring quality is built in at the source.

- Strengthens teamwork between engineering, operations, and quality.

A Process FMEA turns lessons from past issues into proactive control measures. It shifts the organization from reacting to failures to preventing them.

3. Process Control Plan

A Process Control Plan defines how stability is maintained after improvements are made. It links daily operations to long-term goals and ensures that standards are consistently applied.

- Aligns process conditions with Hoshin Kanri (policy deployment).

- Connects short-term problem-solving with long-term strategy.

- Establishes conditions for repeatability and process consistency.

- Prevents performance drift by defining control points and responses.

The Process Control Plan transforms improvement from a one-time result into a managed system.

Integrating These Tools into Lean TPS

When used together, these three tools create the Lean TPS Quality Framework:

- Process Flow Diagram clarifies the current state.

- Process FMEA prevents potential failures.

- Process Control Plan sustains improvements over time.

Applied as an integrated system, they link flow, risk prevention, and control. This combination strengthens quality at every stage of the process and reinforces the principle that quality must be designed and maintained, not inspected in.

Building a Culture of Continuous Improvement

The power of Lean TPS lies not only in the tools but in the culture they create. When these methods become daily habits, the organization moves from firefighting to proactive improvement.

- Proactive Problem-Solving: Teams detect and correct issues at the source.

- Knowledge Sharing: Lessons learned become part of standardized work.

- Employee Engagement: Everyone participates in process improvement and takes ownership of results.

In a true Lean TPS environment, improvement is a shared responsibility. Leadership sets the direction, teams develop the process, and everyone contributes to continuous learning and quality enhancement.

Final Reflection

Are your processes visualized, standardized, and controlled?

Are you preventing defects through structured FMEA reviews?

Are improvements sustained through effective control planning?

Lean TPS builds the foundation for operational excellence through disciplined use of these three tools. When they are applied consistently, improvement becomes a natural outcome of daily work.