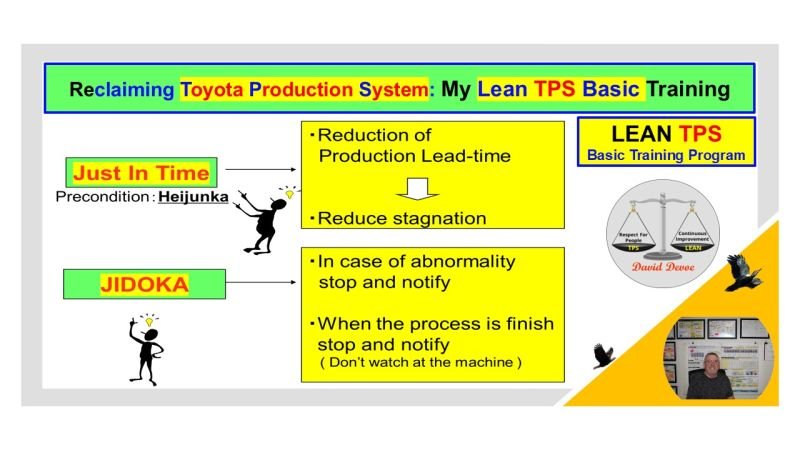

Just in Time (JIT) is one of the two main pillars of the Toyota Production System, together with Jidoka. It ensures that production aligns precisely with customer demand, minimizing waste and maintaining stability throughout the process.

My Lean TPS approach is built on these same principles. JIT is not a scheduling system; it is a management philosophy that integrates flow, timing, and problem-solving to achieve operational excellence.

The Purpose of JIT

The objective of JIT is to produce only what is needed, when it is needed, and in the exact quantity required. This eliminates waste from overproduction, reduces lead time, and enables smoother operations.

At Toyota, JIT was the method that connected every process—from supplier delivery to customer shipment—into a continuous and balanced flow. It required precision, discipline, and teamwork at every level of the organization.

Core Principles of JIT

- Takt Time: Synchronize production with the rate of customer demand. Each process produces at a steady rhythm that prevents overproduction.

- Pull Systems: Downstream processes pull parts only when needed, creating a responsive and balanced workflow.

- Kanban: Visual signals manage inventory and ensure material replenishment occurs exactly when required.

- Heijunka (Leveling): Production is leveled by volume and mix to absorb fluctuations in demand without disrupting flow.

These principles ensure that the entire value stream operates as a coordinated system rather than isolated functions.

JIT in Action at Toyota

During my experience at Toyota, JIT principles were applied across operations including welding, painting, and quality engineering. Each area depended on precise coordination and standardization.

For JIT to succeed, three key conditions were always maintained:

- Stable Processes: Equipment, quality, and work methods must be reliable to sustain consistent output.

- Supplier Coordination: Materials must arrive on time and in the correct sequence to maintain flow.

- Employee Engagement: Associates must be empowered to identify and resolve problems immediately.

The combination of Kanban, Heijunka, and Andon made this system visible and manageable in real time. Each process was designed to reveal problems early, allowing immediate corrective action.

Key Benefits of JIT

- Efficiency: JIT eliminates overproduction, reduces waiting, and balances workloads across processes.

- Quality: By exposing abnormalities immediately, defects are prevented rather than detected later.

- Cost Reduction: Lower inventory levels and improved flow reduce carrying costs and operational waste.

- Agility: The system adjusts quickly to changing customer needs without excess capacity or backlog.

Beyond Manufacturing

While JIT was developed in manufacturing, its principles apply across industries.

- Retail and E-Commerce: Inventory is replenished based on actual demand rather than forecasts.

- Healthcare: Medical supplies and pharmaceuticals are delivered when needed, reducing waste and storage costs.

- Service and Logistics: Streamlined workflows improve timing and responsiveness to customer requirements.

Any environment that manages flow, timing, or resources can apply JIT to achieve predictable performance and customer satisfaction.

The Connection to Jidoka

JIT cannot stand alone. It works in balance with Jidoka, the principle of building quality into the process. While JIT ensures smooth flow, Jidoka ensures that flow is stopped immediately when an abnormality occurs.

When both principles are applied together, processes become self-regulating, stable, and efficient. Problems are visible, and improvement becomes continuous.

Final Reflection

JIT is not a cost-cutting measure. It is a disciplined system that connects people, process, and purpose. When implemented correctly, it builds a foundation for flow, quality, and respect for people.

My Lean TPS Basic Training teaches how to integrate JIT into daily operations through Heijunka, Kanban, and Standardized Work. This structure allows organizations to deliver consistent quality while maintaining flexibility and efficiency.