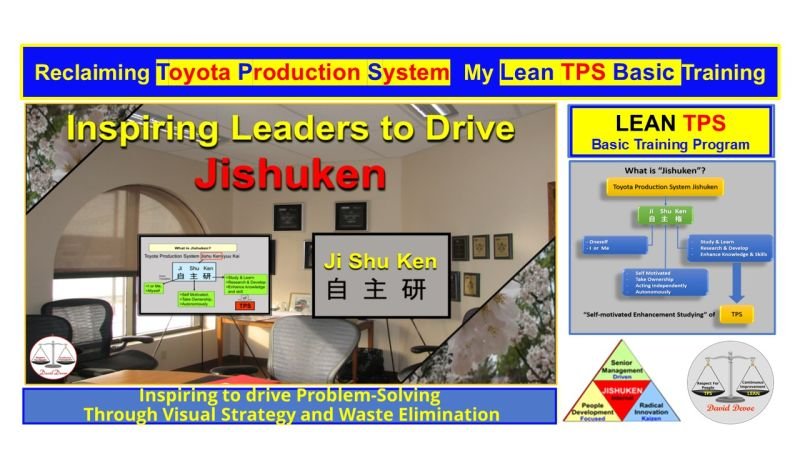

Leadership in Lean TPS is not defined by position but by participation. True leaders develop through structured problem-solving, reflection, and mentorship. This is the essence of Jishuken a leadership development system built on action, collaboration, and learning at the Gemba.

What Is Jishuken?

Jishuken (自主研修) translates to “self-motivated study group.” Within Toyota, it is the mechanism that develops leadership capability through real improvement work. Teams identify problems, study processes, test countermeasures, and sustain results. The purpose is not only to improve the process but to improve the people responsible for it.

Jishuken connects the technical system (problem-solving, standardization, waste elimination) with the human system (learning, coaching, teamwork). The Lean TPS 6D Leadership Framework formalizes this connection.

The Lean TPS 6D Leadership Framework

1. Determine Direction (Goals)

Leaders begin by setting clear direction aligned with organizational objectives. Every Jishuken starts with purpose. This ensures improvement activities are strategic, not reactive, and contribute directly to business priorities.

2. Determine Scope (Objectives)

Scope defines focus. Leaders clarify what needs improvement, why it matters, and how success will be measured. Jishuken requires disciplined boundary setting to ensure results are measurable and sustainable.

3. Develop People (Inspiration and Learning)

The foundation of Jishuken is learning by doing. Leaders coach team members through structured improvement activity, helping them develop analytical skills, discipline, and confidence. Every improvement cycle strengthens capability.

4. Develop Teams (Collaboration and Leadership Growth)

Improvement requires teamwork. Leaders facilitate collaboration, establish trust, and encourage every member to contribute. This shared ownership accelerates improvement and strengthens organizational culture.

5. Drive a Scientific Approach (Structured Problem-Solving)

Jishuken applies a disciplined PDCA cycle. Leaders go to the Gemba, observe conditions firsthand, and apply A3 thinking to identify true causes. Facts, data, and verification replace assumption and opinion.

6. Deliver Natural Results (Sustained Change and Innovation)

When leaders focus on process discipline and people development, results occur naturally. Jishuken does not chase outcomes. It builds the conditions where improvement becomes a habit, not a reaction.

Structured Pathways to Leadership

Toyota’s Jishuken method develops leadership progressively through levels of responsibility and scope:

- Apprentice Level: Learning standardized work, understanding waste, and applying basic Kaizen.

- Quality Circle (QCC) Level: Leading small group problem-solving within defined processes.

- Internal Jishuken Level: Coordinating plant-wide improvement projects across departments.

- Advanced Jishuken Level: Coaching suppliers, mentoring future leaders, and strengthening value stream performance.

Each level reinforces leadership through direct experience, reflection, and teaching. This cycle ensures that leaders grow by engaging deeply with problems rather than managing from a distance.

Leadership Through Thinking, Doing, and Teaching

Jishuken creates leaders who:

- Think critically through structured problem-solving.

- Act decisively based on facts gathered at the Gemba.

- Teach others to think and improve through coaching and example.

The 6D Framework ensures leadership development remains structured and repeatable. It provides a roadmap for organizations to embed improvement capability across every level.

When leaders learn through Jishuken, improvement becomes continuous, learning becomes shared, and leadership becomes visible in action.

This is how Lean TPS builds leaders not by authority, but through disciplined practice and daily problem-solving.