Leadership in Lean TPS is developed through action, reflection, and problem-solving. True leadership is not about authority or position but about capability, discipline, and learning through experience.

At Toyota, Jishuken is a structured method for developing leaders who can think, act, and teach. It connects leadership growth directly to improvement activity, creating a system where learning and results progress together.

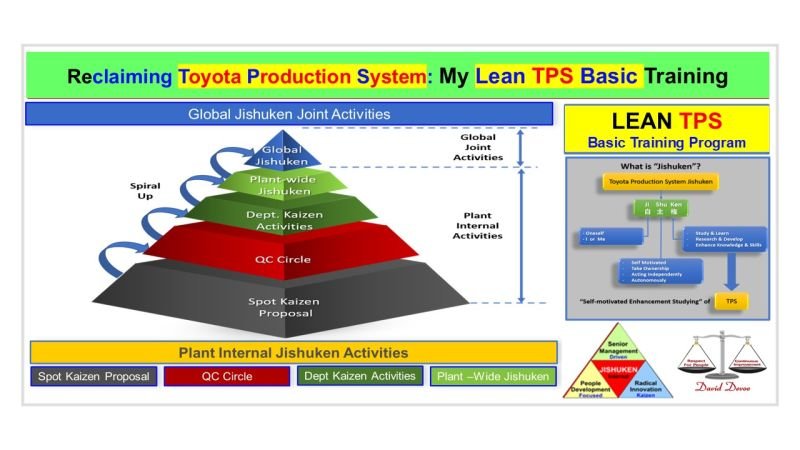

The Purpose of Jishuken

Jishuken (自主研修) means self-motivated study. It is Toyota’s approach to developing leadership through structured improvement. Jishuken groups work on real production or business challenges, analyzing causes and applying countermeasures through continuous study.

This method develops two key capabilities:

- The ability to see and solve problems through structured analysis.

- The discipline to coach others and sustain improvement across processes.

Jishuken is not a meeting or a project. It is a leadership development cycle embedded into daily work. Every member learns how to identify abnormal conditions, apply the 5 Whys, and use Standardized Work to prevent recurrence.

The Jishuken Learning Progression

The image above illustrates how Toyota structures the Jishuken learning journey. It begins with plant-level improvement and progresses through increasingly complex systems of learning and collaboration.

1. Spot Kaizen Proposals

At the entry level, team members participate in Spot Kaizen improvements focused on local issues. The goal is to build awareness of waste, practice structured problem-solving, and strengthen observation skills.

2. Quality Control Circles (QCC)

Small groups work on defined problems using quality tools such as Pareto Charts, Fishbone Diagrams, and 5 Whys. QCCs build teamwork, analytical ability, and consistency in using visual management tools.

3. Department Kaizen Activities

Leaders begin coordinating cross-functional problem-solving. Improvements now span multiple processes, requiring communication, measurement, and coordination. These activities teach leaders how to connect systems rather than optimize single points.

4. Plant-Wide Jishuken

At this level, leaders integrate multiple departments into joint problem-solving activities. Teams study flow, takt alignment, and quality control systems, ensuring that improvements link directly to business goals.

5. Global Jishuken Joint Activities

The highest level connects plants, suppliers, and global operations. Senior leaders engage in shared learning across facilities, reviewing systems together to strengthen consistency, knowledge transfer, and long-term stability.

This structured progression ensures leadership is developed through participation, not instruction. Each level builds deeper capability in both process and people development.

Leadership Through Thinking, Doing, and Teaching

In Jishuken, leaders are not distant observers. They are active participants who lead by example. The process requires leaders to think critically, apply what they learn, and teach others through practice.

- Thinking: Leaders observe reality and clarify facts before making decisions.

- Doing: They take direct responsibility for applying countermeasures and confirming results.

- Teaching: They pass on what they learn, reinforcing discipline and ensuring sustainability.

When these three behaviors become daily habits, leadership growth accelerates naturally.

The Spiral of Continuous Learning

The Jishuken pyramid in the visual also represents the spiral of learning. As leaders progress through Spot Kaizen, QCC, Department Kaizen, Plant Jishuken, and Global Jishuken, they do not move linearly upward but continuously cycle back through the fundamentals with greater depth and understanding.

Each new level builds on the last, strengthening problem-solving skills, deepening process knowledge, and reinforcing the value of teamwork.

Building a Culture of Leadership Development

Organizations that apply Jishuken effectively create a culture where leadership is developed systematically. Improvement becomes the training ground for future leaders. Senior managers coach through observation, middle managers coordinate problem-solving, and frontline teams learn by doing.

This structure ensures that leadership is never limited to a few individuals. It becomes a shared responsibility across the organization.

A Lean TPS organization built on Jishuken does not rely on authority or control. It relies on people who can see waste, understand causes, and take disciplined action to improve.

Closing Thought

Developing leaders through Jishuken is not optional in a Lean TPS environment. It is the core mechanism that connects people development to process improvement. When leadership growth and continuous improvement are aligned, performance becomes sustainable, and culture becomes self-reinforcing.