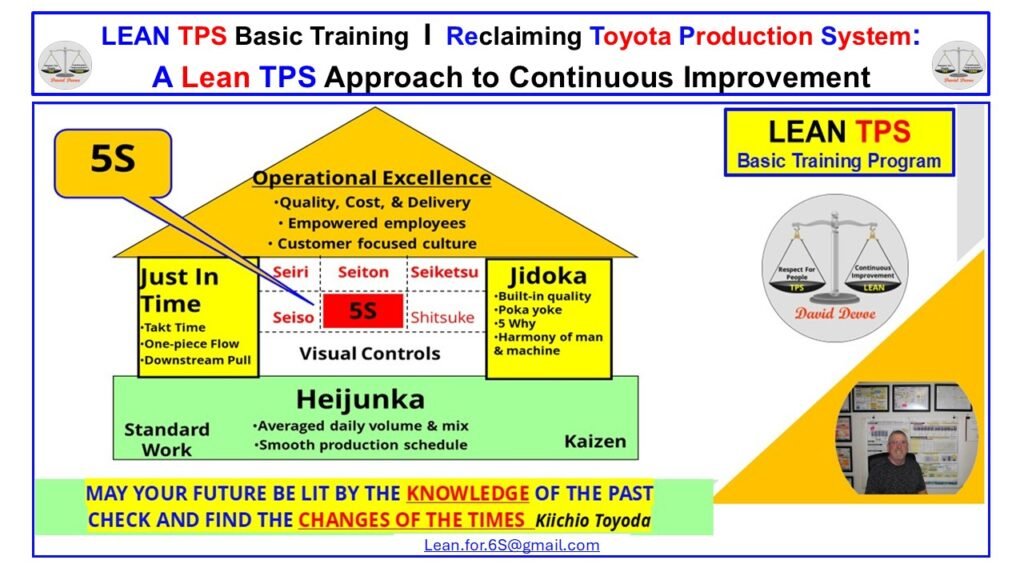

When people first see the Toyota Production System (TPS) house, they often focus on the roof—operational excellence, quality, and cost. Yet the true strength of TPS begins at the base. The foundation is built on 5S Thinking, Standardized Work, Heijunka, and Kaizen. Without these, the pillars of Just In Time and Jidoka cannot stand.

5S Thinking is not housekeeping. It is the structure that makes Lean TPS work. At Toyota, 5S creates the environment where flow can begin, quality can be maintained, and improvement can take root. It teaches discipline, reveals waste, and builds a shared visual language for how work should be performed.

The five steps—Sort (Seiri), Set in Order (Seiton), Shine (Seiso), Standardize (Seiketsu), and Sustain (Shitsuke)—are not isolated activities. They form a cycle of organization and learning. Sorting eliminates what is unnecessary. Setting in order defines what belongs and where. Shine ensures that cleaning is inspection. Standardize creates repeatable practices. Sustain transforms good habits into culture.

At Toyota, 5S is inseparable from Just In Time and Jidoka. Together they define the balance between people, process, and quality. Just In Time aligns production with customer demand, while Jidoka builds in quality through human judgment and machine support. Both depend on visual controls and structure created by 5S.

Heijunka, or production leveling, connects these systems by balancing workload and stabilizing output. Standardized Work establishes consistency. Kaizen brings continuous reflection and adjustment. These elements are not departments or projects; they are interdependent systems that reinforce each other.

When the foundation is weak, the system collapses under pressure. When 5S is strong, flow, quality, and efficiency naturally follow. 5S exposes waste, improves communication, and builds the confidence required to act. Every visual mark, standard, and routine becomes a signal of stability and respect for people.

The quote from Kiichiro Toyoda captures this idea clearly:

“May your future be lit by the knowledge of the past. Check and find the changes of the times.”

It reminds us that progress depends on learning and adaptation, not slogans or programs.

The house of TPS is not an image to display. It is a way to build. When 5S Thinking becomes the daily structure of work, the rest of the system grows from it naturally.