Change is constant in every organization, but how it is managed determines whether operations remain stable or fall into disruption. At Toyota, I learned that Change Point Management (CPM) is the foundation for stability, quality, and sustainable improvement.

Without structured oversight, even small changes can introduce variation, inefficiency, and defects that disrupt performance. Toyota developed Change Point Management to ensure every modification is understood, controlled, and verified before implementation.

What Change Point Management Controls

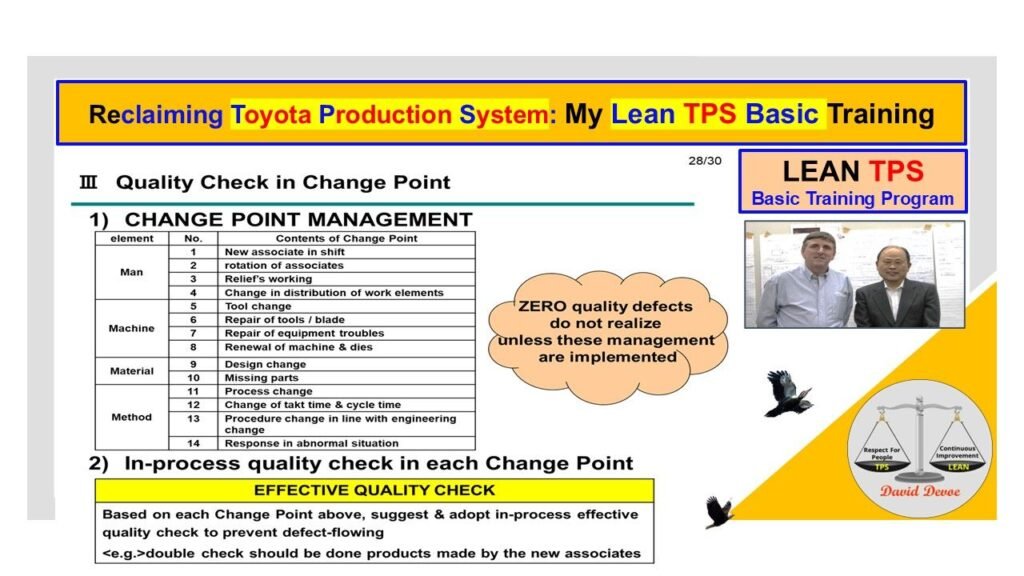

Toyota’s Change Point Management process monitors and stabilizes key changes in four categories:

- Man (People): A new associate or role change requires training and verification to maintain standard quality and consistency.

- Machine: Equipment adjustments, tooling changes, or new machines require validation to ensure process capability.

- Material: New materials or suppliers must be tested and integrated without compromising standards or flow.

- Method: Any process update or change in work sequence must sustain safety, efficiency, and standardized work.

Each change point is assessed, documented, and tracked to identify potential risks. The process ensures that every improvement aligns with the Toyota Production System (TPS) principles of standardization, quality, and flow.

The Role of the Asaichi Meeting

At Toyota, the Asaichi meeting—held at the start of each shift—served as the daily control point for change management. Leaders reviewed any modifications to manpower, machines, materials, or methods to confirm readiness and prevent unexpected variation.

Every change was evaluated for its potential impact on safety, quality, and productivity. This structured daily review prevented reactive problem-solving and allowed teams to maintain process stability while implementing improvements.

A Practical Example: Takt Time Adjustment

During my time at Toyota, a simple takt time adjustment illustrated the importance of Change Point Management. A small change to balance workflow required complete coordination between engineering, operations, and quality.

The team used CPM to conduct a structured risk assessment before implementing the new takt. This ensured that no bottlenecks or quality concerns emerged during the transition. Through precise control and validation, the change was introduced successfully with zero defects and improved flow efficiency.

This example reinforces a central truth: change at Toyota is never left to chance. Every modification is analyzed, tested, and standardized before being integrated into production.

Why Structured Change Matters

Organizations that lack structured change management often experience recurring quality issues, waste, and inconsistent results. Without a process to control change, even small improvements can create new instability.

Change Point Management transforms how organizations view improvement. Instead of reacting to problems, they prevent them by managing change systematically. This structured discipline ensures that improvement is intentional, traceable, and sustainable.

The Lean TPS Approach

My Lean TPS Change Point Management training emphasizes the same disciplined approach used by Toyota. It teaches leaders and teams how to identify change points, assess risk, and verify stability before and after implementation.

Key outcomes include:

- Improved quality through preventive control of changes.

- Reduced variability by maintaining standardization.

- Enhanced communication between leadership and operators.

- Sustained improvement through daily monitoring and review.

Change Point Management is not just a quality method. It is a leadership mindset that connects people, process, and problem-solving in a structured system.

Managing Change the Toyota Way

Change is inevitable, but instability is not. My Lean TPS approach ensures that organizations make the right changes, in the right way, at the right time.

When applied correctly, Change Point Management builds confidence, reduces defects, and strengthens the culture of continuous improvement. It converts uncertainty into structured progress and makes every improvement an opportunity to learn and grow.