In Lean TPS, Standardized Work is not a document. It is the system capability that allows people to see problems as they happen and respond with speed and precision. Without it, waste, unevenness, and overburden remain hidden.

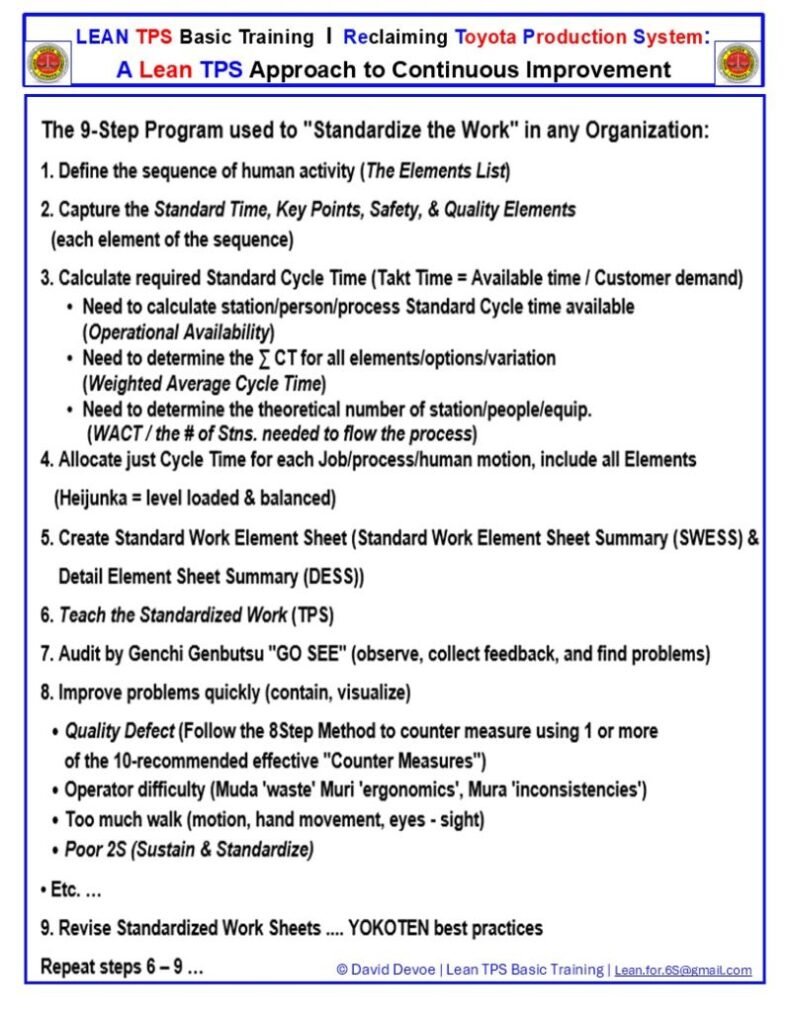

The Lean TPS 9-Step Method was developed from how capability was built inside Toyota. Each step is practical, teachable, and connected to real flow at the Gemba.

1. Define the sequence of human activity

Build the elements list from what is actually done, not what should be done. Capture each step at the Gemba by observing the real work.

2. Capture standard time, key points, safety, and quality

Record accurate times for each element. Include safety checks, quality requirements, and teaching points that guarantee consistency.

3. Calculate the required Standard Cycle Time

Base the cycle on takt time. Factor in available time, product mix, variation, and operational availability to determine a stable pace.

4. Allocate cycle time for each job or task

Balance workload using Heijunka. Distribute work evenly across people, stations, and machines to avoid bottlenecks and overburden.

5. Create the Standard Work Element Sheet

Document the sequence, times, and key points for success. Use Standard Work Element Sheet Summary (SWESS) and Detail Element Sheet Summary (DESS) formats.

6. Teach the Standardized Work

Train people in both the how and the why. Show how each step connects to flow, safety, and quality.

7. Audit using Genchi Genbutsu

Go and see the work. Confirm that the standard is being followed, collect feedback, and identify improvement opportunities.

8. Improve problems quickly

Visualize and act on problems as they appear. Address quality defects, operator difficulties, motion waste, and poor 2S practices through structured countermeasures.

9. Revise Standardized Work through Yokoten

Share and standardize best practices across teams. When an improvement raises performance, it becomes the new standard.

Steps six through nine form the improvement loop. Teaching, auditing, acting on problems, and sharing improvements create the rhythm that sustains progress and develops capability.

In Lean TPS, Standardized Work is never static. It evolves through daily practice and disciplined improvement cycles. It creates stability, enables flow, and builds respect for people by providing clarity and structure for success.