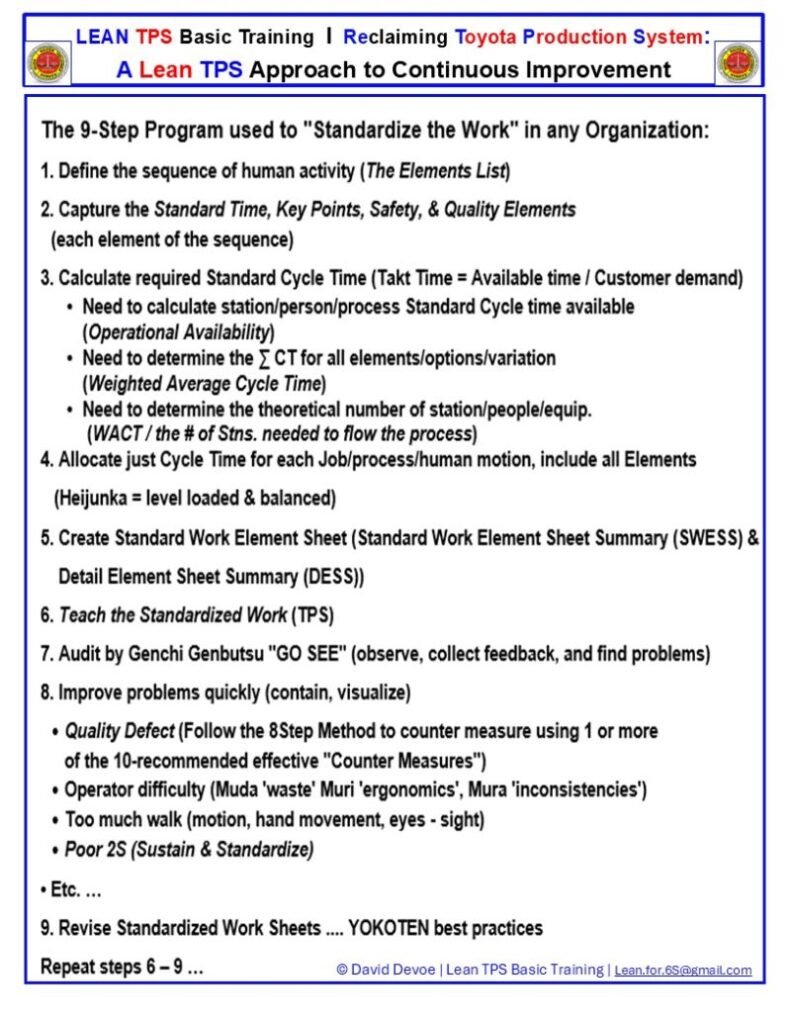

Standardized Work is the capability that keeps Lean TPS from collapsing into firefighting. It creates a clear picture of how people, machines, and materials interact. The 9-Step Method describes how to establish that picture, teach it, confirm it, and improve it. Each step has a defined purpose, inputs, activities, outputs, and leader checks.

Step 1. Define the Sequence of Human Activity

Purpose: Capture reality, not intention.

Inputs: Product family, station scope, model mix, shift pattern.

Activities:

- Go to the Gemba and list every task performed to make one unit or complete one service cycle.

- Record the order actually followed by the operator.

- Note safety points, quality checkpoints, hand transfer points, and machine interactions.

Outputs: Elements List with unique IDs, clear start and end for each element.

Leader checks: The list reflects what is happening now. No assumptions. No missing handoffs. Operator validates the order.

Step 2. Capture Standard Time, Key Points, Safety, and Quality

Purpose: Define the conditions that make success repeatable.

Inputs: Elements List.

Activities:

- Measure element times with stopwatch or time study software. Use enough cycles to stabilize the average.

- Write key points that explain how to perform the element correctly.

- Record explicit safety conditions and quality requirements.

- Identify variables or options that change time or method.

Outputs: Time per element, key point notes, safety and quality flags linked to each element.

Leader checks: Times collected at the process. Key points teach the why. Safety and quality conditions are specific and observable.

Step 3. Calculate Required Standard Cycle Time

Purpose: Establish the pace required to meet demand without overburden.

Inputs: Customer demand, available operating time, losses and planned downtime, model mix.

Activities:

- Calculate takt time: available time divided by customer demand.

- Determine standard cycle time for the station or person.

- For mixed models, calculate weighted average cycle time and variation range.

- Estimate the theoretical number of stations or people required to achieve flow.

Outputs: Takt time, standard cycle time, mix assumptions, and staffing calculation.

Leader checks: Assumptions are visible. Availability reflects reality. Mix logic matches the production plan.

Step 4. Allocate Cycle Time and Balance the Work

Purpose: Level the load so flow can hold.

Inputs: Element times, takt time, staffing calculation.

Activities:

- Assign elements to people or stations so the sum of manual time per cycle is at or below takt.

- Consider walking distance, reach, ergonomic posture, and machine overlap.

- Remove obvious waste and combine compatible elements to reduce motion and waiting.

- Use small layout moves before large ones.

Outputs: A balanced allocation that meets takt with margin for normal variation.

Leader checks: No hidden overload. Ergonomics acceptable. Travel minimized. First pass yield protected.

Step 5. Create the Standard Work Element Sheet

Purpose: Turn the design into teachable, auditable instructions.

Inputs: Balanced allocation, element times, key points.

Activities:

- Build the Standard Work Element Sheet Summary (SWESS): ordered list of elements with time, key points, and safety or quality icons.

- Create the Detail Element Sheet Summary (DESS) if complexity requires more explanation or photos.

- Draw the Standardized Work Chart (SWC): top view of the station with operator path, part locations, machine positions, and inspection points.

- Draft the Standardized Work Combination Table (SWCT): plot manual, machine, walk, and wait time against takt for one complete cycle.

Outputs: SWESS, DESS, SWC, SWCT in draft form, ready for training.

Leader checks: Sheets are readable at the station. Graphics match the real layout. Times on SWCT equal the sum of elements.

Step 6. Teach the Standardized Work

Purpose: Build capability so the standard can live.

Inputs: SWESS, DESS, SWC, SWCT.

Activities:

- Train one-point lessons for critical safety and quality items.

- Use job instruction style: prepare the learner, present the job, try out performance, follow up.

- Teach the reason for sequence, not only the steps.

- Verify understanding with return demonstration at full pace.

Outputs: Trained operators who can perform the standard safely, at quality, and at takt.

Leader checks: Training records complete. New members meet the standard within a defined ramp period. Questions and concerns are captured for improvement.

Step 7. Audit by Genchi Genbutsu

Purpose: Confirm that the standard is followed and still effective.

Inputs: Trained process, current sheets.

Activities:

- Go and see. Observe whole cycles without interruption.

- Check sequence adherence, point of use locations, and visual controls.

- Review SWCT against observed time. Note drift, shortages, or new interference.

- Capture operator feedback and small abnormalities immediately.

Outputs: Audit findings, gap list, and photos or sketches.

Leader checks: Audits are scheduled in leader standard work. Findings are acted upon quickly. The tone is coaching, not policing.

Step 8. Improve Problems Quickly

Purpose: Remove barriers and protect rhythm.

Inputs: Audit gaps, operator feedback, daily problem logs, quality alerts.

Activities:

- Triage problems by risk to safety, quality, and flow.

- Contain issues with simple visual countermeasures.

- Use quick PDCA for small gaps. Use A3 thinking for larger, recurrent issues.

- Update SWC and SWCT as trials change layout, sequence, or timing.

Outputs: Implemented countermeasures with verified effect on safety, quality, and cycle time.

Leader checks: Verification data exists. Effects are visible on the floor. The team knows what changed and why.

Step 9. Revise Standards and Share by Yokoten

Purpose: Lock in learning and spread it.

Inputs: Verified countermeasures and new timings.

Activities:

- Update SWESS, DESS, SWC, and SWCT to reflect the new best method.

- Retrain affected members and adjust leader standard work and audit points.

- Share the improvement with sister areas or similar processes.

- Capture before and after evidence for teaching.

Outputs: Current, controlled standards and a record of yokoten.

Leader checks: Old versions are removed. Training complete. Similar areas considered and scheduled for adoption.

How the 9 Steps Connect to Kaizen, Jidoka, and Just in Time

- Kaizen: Steps 6 to 9 form the improvement loop. Teach, confirm, correct, and stabilize. The cycle prevents backsliding and creates a cadence for daily learning.

- Jidoka: Safety and quality conditions are embedded in Steps 2, 5, and 7. Abnormality is designed to be visible. Stopping is expected when conditions are not met.

- Just in Time: Steps 3 and 4 align work to takt and balance. Flow is created through leveling, short travel, and clear handoffs.

When these links are active, the system prevents failure rather than reacting to it.

Practical Artifacts and Where They Live

- At the station: SWESS, SWC, and the most current SWCT, laminated or posted in a protected sleeve at eye level.

- With the team leader: Training matrix, audit checklist, and a small binder with current and prior versions for reference.

- In the area office: A3 records for significant changes, yokoten log, and the improvement calendar.

Common Failure Modes and Countermeasures

| Failure mode | Countermeasure |

|---|---|

| Elements list written from memory | Rebuild Step 1 at the Gemba with the operator. |

| Times averaged from old reports | Re-measure Step 2 with direct observation and video sampling. |

| Takt time wrong | Reconfirm demand and availability. Recalculate Step 3. |

| Balance looks perfect on paper but fails on floor | Walk the path. Correct layout and reach in Step 4 before training. |

| Sheets filed, not used | Post at the station and include in leader standard work, Step 7. |

| No verification of changes | Require before and after data in Step 8. |

| Old versions still in circulation | Version control in Step 9 with visible dates and signatures. |

Example Flow for a New Product Variant

- Map the new sequence at the bench with the operator.

- Time the new elements and mark key risk points.

- Recalculate takt and weighted mix.

- Rebalance two tasks to remove 8 seconds of walking.

- Update SWESS, SWC, and SWCT.

- Train two members and one relief.

- Audit the line at start of shift and after break.

- Add a point of use shelf and a color mark to prevent a quality slip.

- Revise drawings and share the shelf idea with two nearby cells.

The result is a stable method that meets takt and prevents quality escapes on day one.

Leadership Responsibilities

- Set the expectation that standards are visual, current, and taught.

- Schedule time to observe and coach at the process.

- Remove barriers quickly when audits reveal problems.

- Recognize teams for verified improvements and yokoten.

- Protect time for training and reflection. The system learns when people have space to learn.

Conclusion

The Lean TPS 9-Step Method is a practical sequence that turns observation into stability and stability into improvement. It defines how to build Standardized Work, how to keep it alive, and how to use it to teach the next improvement. When the steps are followed with discipline, the workplace becomes predictable, safe, and ready for Kaizen.