In the Toyota Production System, improvement begins with structure, not slogans. The foundation of that structure is 5S Thinking. It is the entry point into disciplined problem solving and the development of Kaizen capability. Before any leader can lead improvement, and before any team can sustain flow, the environment itself must teach stability and respect through visual order.

The five elements of 5S, Sort, Set in Order, Shine, Standardize, and Sustain, were never housekeeping tasks. They were the first lessons in leadership and self-discipline. Each step built the foundation for seeing waste, controlling abnormalities, and linking small improvements into system-level performance. The goal was not a cleaner workspace. It was to make the condition of the work visible so that anyone, at any time, could detect deviation from standard.

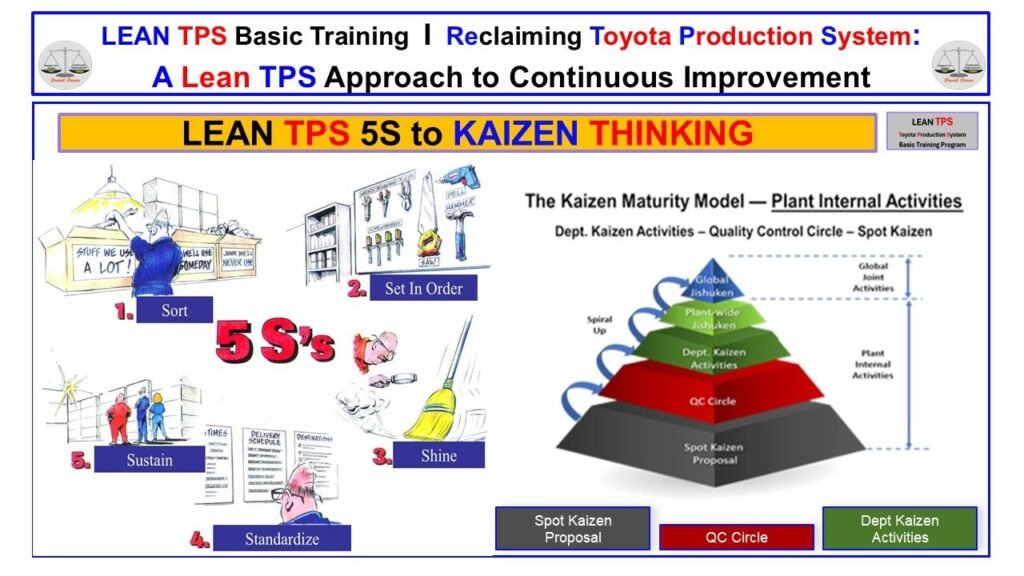

1. Sort begins with the removal of unnecessary items. This act alone changes behavior. It forces people to decide what is truly needed and what only adds clutter. 2. Set in Order establishes a defined home for every tool and material. Visual control develops naturally because everything has a purpose and a location. 3. Shine ensures every surface and piece of equipment is maintained, revealing early signs of wear or contamination. 4. Standardize locks in these practices across shifts, areas, and departments so that each workspace reflects the same operating logic. 5. Sustain reinforces discipline through leader checks, daily accountability, and reflection. Together, these steps create an environment that teaches process awareness and exposes weakness before it becomes failure.

At Toyota BT Raymond, this method was practiced daily. The Red Tag process was not a clean-up exercise. It was a coaching mechanism. When an item was tagged for review, leaders would not simply remove it. They would ask why it was there, what purpose it served, and how its absence would affect the process. This dialogue built awareness of waste and taught how to separate value-adding from non-value-adding activity. In this way, 5S became a learning cycle that developed capability rather than compliance.

Once 5S Thinking was established, Kaizen Thinking followed naturally. The image shows the Kaizen Maturity Model used in Lean TPS Basic Training. At the base of the spiral is the Spot Kaizen Proposal, where individuals identify and correct small issues. Above this, the Quality Control Circle (QC Circle) forms around shared problem solving within a team. Department Kaizen Activities connect those improvements to cross-functional processes, while Plant-wide and Global Jishuken unite leadership and members to study and correct systemic instability. Each layer depends on the discipline below it. Without 5S, the upper layers collapse because daily problems remain hidden.

In Toyota, the phrase “You cannot improve what you cannot see” was more than a teaching point. It was the structure of learning. Leaders were expected to coach 5S before introducing Kaizen, because 5S created the environment where cause and effect could be understood. When the workplace was stable, patterns emerged. Teams began to identify recurring problems, test ideas, and reflect on results. This was Kaizen Thinking the ability to see variation, act immediately, and learn systematically from experience.

5S Thinking is not a separate program from Kaizen. It is the first half of the same discipline. In Lean TPS, 5S builds the conditions for continuous improvement, while Kaizen transforms those conditions into capability. Together, they connect Standardized Work, Jidoka, and Just-in-Time into one complete operating system. This structure makes Lean TPS sustainable because it integrates leadership, teamwork, and system design into daily practice.

Many organizations still treat 5S as an entry-level activity or short-term campaign. In Toyota, 5S was the starting point of leadership training. Supervisors were judged on how well their teams maintained standards and improved them over time. This practice ensured that 5S Thinking was not an isolated initiative but a reflection of the culture itself. By mastering 5S, teams built the discipline to sustain Kaizen, and leaders built the awareness to prevent regression.

Lean TPS 5S to Kaizen Thinking is the true path of development inside Toyota. It is how the organization grows capability from the ground up, one standard at a time. The foundation is order. The outcome is learning. The system that connects them is leadership.