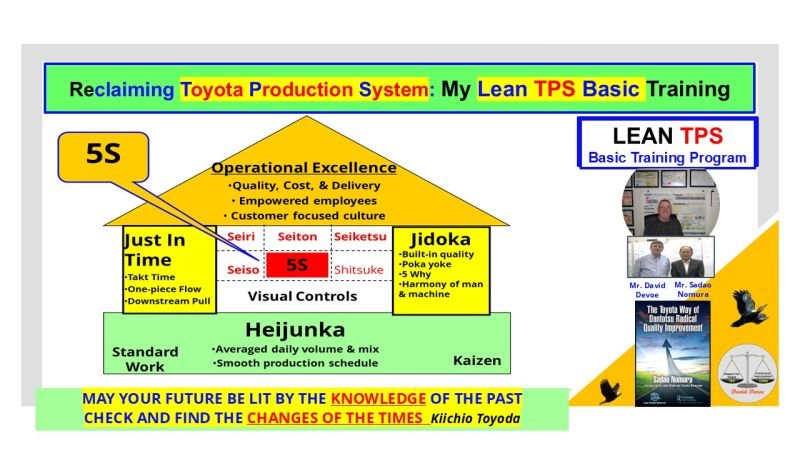

5S Thinking is more than workplace organization. It is the foundation of Toyota’s approach to operational excellence. Within the Toyota Production System (TPS), 5S Thinking evolved from a housekeeping tool into a disciplined method that eliminates waste, stabilizes processes, and builds a culture of continuous improvement.

5S Thinking in the Toyota Production System

Toyota’s 5S principles establish the foundation for efficiency, problem-solving, and respect for people. Each step reinforces stability and standardization, forming the base of every improvement initiative.

- Sort (Seiri) – Remove unnecessary items and sharpen focus on what adds value.

- Set in Order (Seiton) – Organize tools, materials, and information for smooth flow.

- Shine (Seiso) – Maintain cleanliness and stability through inspection and upkeep.

- Standardize (Seiketsu) – Create repeatable processes that prevent variation.

- Sustain (Shitsuke) – Build discipline and accountability to ensure improvements endure.

When properly applied, 5S Thinking becomes a learning system that teaches teams how to identify waste, solve problems, and continuously improve their own work areas.

Nomura’s Influence on 5S and 2S Thinking

In his 2007 paper on Quality Kaizen through the Toyota Production System, Mr. Sadao Nomura wrote that “2S is not about putting away and hiding for appearance but eliminating all kinds of waste.”

This statement reflects the deeper purpose behind 5S Thinking. The goal is not visual tidiness. It is systematic waste elimination. When 5S matures, the focus shifts naturally to 2S Thinking—Standardize and Sustain—ensuring that improvements are consistent and permanent.

I applied this learning after returning from Toyota L&F (Logistics and Forklifts) in Takahama, Japan. By improving 2S within our Lean TPS framework, we eliminated inefficiencies at the source and developed leadership-driven improvement systems that delivered measurable results.

Leadership’s Role in Sustaining 5S Thinking

At Toyota, leadership participation is central to every improvement activity. 5S Thinking is not delegated to teams. It is modeled by leaders who create the environment for discipline, learning, and respect.

Through Lean TPS Basic Training, 5S becomes a visible part of leadership development. Managers learn to see waste, standardize expectations, and coach employees to sustain improvement.

This structure ensures that 5S is not treated as a short-term initiative but as a foundational element of TPS—embedded into daily work, audits, and visual management systems.

Real-World Results from 5S Thinking

Structured 5S Thinking consistently produces measurable improvements in quality, safety, and cost.

- A Toyota Management System initiative reduced production from three shifts to one while maintaining output.

- In a quarry operation, a disciplined 5S program reduced maintenance costs by 70 percent.

- A Jishuken-led 5S transformation eliminated inefficiencies valued at eighteen million dollars annually.

Each of these examples demonstrates that 5S Thinking, when integrated with Standardized Work and leadership participation, creates stability and profitability without adding complexity.

Applying 5S Thinking in Your Organization

Every successful Lean transformation begins with the disciplined practice of 5S Thinking. It provides a framework for improvement that connects people, process, and leadership.

Implementation steps include:

- Lean TPS Basic Training – Introduces 5S Thinking and connects it to organizational goals.

- On-Site Workshops – Builds capability through hands-on experience in real workplace transformation.

- Leadership Coaching – Ensures leaders develop the habits and structure to sustain 5S practices.

When 5S Thinking becomes part of daily operations, organizations experience reduced waste, improved flow, and a stronger foundation for Kaizen and Jishuken activities.

Final Thought

5S Thinking is not the end point of improvement. It is the beginning. It builds the structure, stability, and mindset required for sustainable success.

As Kiichiro Toyoda said, “May your future be lit by the knowledge of the past. Check and find the changes of the times.”

The discipline of 5S provides that light—connecting knowledge, leadership, and continuous improvement in every workplace.