The Toyota Production System is not built on tools. It is built on disciplined thinking. For more than a decade, I applied these principles in real operations, learning how the foundation of 5S Thinking supports sustainable success. My Lean TPS 5S Thinking integrates the original discipline of Japanese TPS with the adaptability required for North American workplaces.

Building the Foundation for Improvement

When Toyota allowed our Canadian facility to be idled, the experience became a turning point. The lesson was clear: without structure and discipline, systems fail. My Lean TPS framework was developed to preserve the integrity of Toyota Production System principles while adapting them for diverse industries. It focuses on developing people, improving processes, and embedding continuous improvement into daily operations.

This system is not about cost-cutting or temporary gains. It is a structured approach that eliminates inefficiency, strengthens safety, and builds respect for people through consistent leadership and practice.

My Lean TPS 5S Thinking

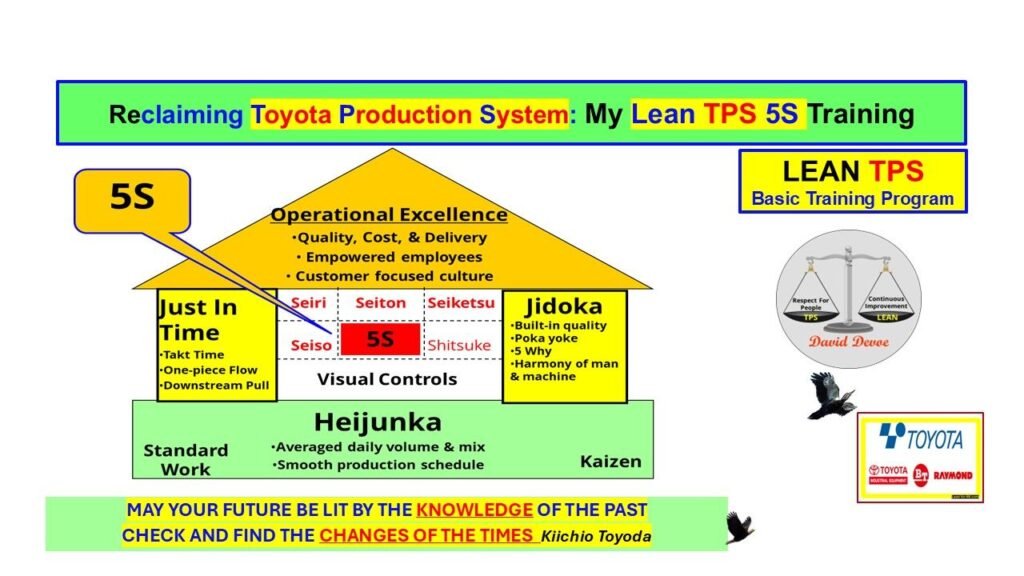

Many organizations misunderstand 5S as a cleaning or housekeeping initiative. In Lean TPS, it is the structural base for problem-solving, efficiency, and respect. Each “S” represents a principle that strengthens workplace stability and capability:

- Sort (Seiri): Remove items that do not add value, creating space for clarity and focus.

- Set in Order (Seiton): Organize tools, equipment, and materials for efficiency and flow.

- Shine (Seiso): Maintain a clean and visible workspace to reveal problems early.

- Standardize (Seiketsu): Establish repeatable routines to ensure consistency across all shifts.

- Sustain (Shitsuke): Embed 5S into culture through daily discipline and accountability.

5S Thinking connects people to process. It teaches that improvement begins with structure and clarity, not with tools or projects. When each step is practiced daily, waste reduction and quality improvement become natural outcomes.

Why Lean TPS 5S Thinking Matters

A strong 5S foundation enables every other element of the Toyota Production System to function effectively. Just In Time, Jidoka, Heijunka, and Kaizen all rely on stable, standardized environments where problems can be seen and corrected immediately. Without 5S, flow breaks down, safety declines, and efficiency is lost.

My Lean TPS 5S Thinking strengthens:

- Safety: Clean, organized areas reduce risk and promote reliability.

- Quality: Visibility ensures problems are found and addressed early.

- Efficiency: Standardized layouts and routines eliminate wasted motion.

- Engagement: Employees participate directly in improvement and sustain results.

In practice, Lean TPS 5S Thinking transforms how people view their work. It develops ownership and pride, reinforcing that discipline is not control but respect for those who do the work.

Sustainable Improvement through Leadership

Leadership determines whether 5S remains a program or becomes culture. In Lean TPS Basic Training, leaders are taught to model these behaviors, not delegate them. Daily checks, visual management, and coaching make 5S a living system. When combined with Standardized Work and Kaizen, it becomes the platform for true operational excellence.

At Toyota, the quote from Kiichiro Toyoda captured this mindset:

“May your future be lit by the knowledge of the past. Check and find the changes of the times.”

Sustaining improvement requires both reflection and adaptation. Lean TPS 5S Thinking provides that balance—linking proven principles to evolving workplaces.

Closing Message

My Lean TPS is a structured and tested approach built on respect, discipline, and learning. When organizations apply 5S Thinking correctly, it becomes the system that prevents failure and supports continuous improvement.

If your goal is to build lasting capability rather than temporary results, Lean TPS 5S Thinking is where the transformation begins.