The Toyota Production System (TPS) is recognized worldwide for its ability to build quality, efficiency, and safety into every process. At its foundation lies 5S Thinking, a structured approach that organizes the workplace and strengthens the behaviors that make continuous improvement possible. My Lean TPS 5S Thinking extends this foundation by connecting daily discipline with leadership learning, operational flow, and Respect for People.

The Foundation of Lean TPS 5S Thinking

5S Thinking is not housekeeping. It is the structure that allows Lean TPS to function. Without it, stability cannot be achieved, and improvement cannot take root. Each of the five steps, Sort (Seiri), Set in Order (Seiton), Shine (Seiso), Standardize (Seiketsu), and Sustain (Shitsuke), represents both a physical and mental practice. Together, they build the conditions where waste is visible, standards are maintained, and people can think and act with confidence.

Sort removes what is unnecessary, exposing space, time, and waste hidden in daily work.

Set in Order defines what belongs and where, reducing motion and confusion.

Shine ensures that cleaning becomes inspection, revealing abnormal conditions.

Standardize establishes consistency, confirming that the best way is performed the same way every time.

Sustain creates habit and culture, turning short-term activity into long-term discipline.

These steps are simple but powerful. At Toyota, 5S is the first learning step in Lean TPS Basic Training. It teaches people to see. It builds awareness of how structure and clarity prevent problems before they occur. It sets the tone for leadership accountability and respect for every worker.

From 5S to 6S: Building Safety into the System

My Lean TPS 5S Thinking adds Safety as the sixth element, forming 6S Thinking. Safety is not an addition but a principle that underpins every action. It represents the highest expression of Respect for People, ensuring that improvement is always aligned with human well-being.

The formula is simple: 5S + 1S = Respect for Workers and Highest Quality Safety.

When 6S Thinking is sustained, work areas become stable and predictable. Problems surface immediately, and corrective action becomes routine. The connection between safety, quality, and efficiency becomes visible. The workplace itself becomes a training ground for leadership and problem-solving.

Integrating 5S into the Lean TPS 5P Model

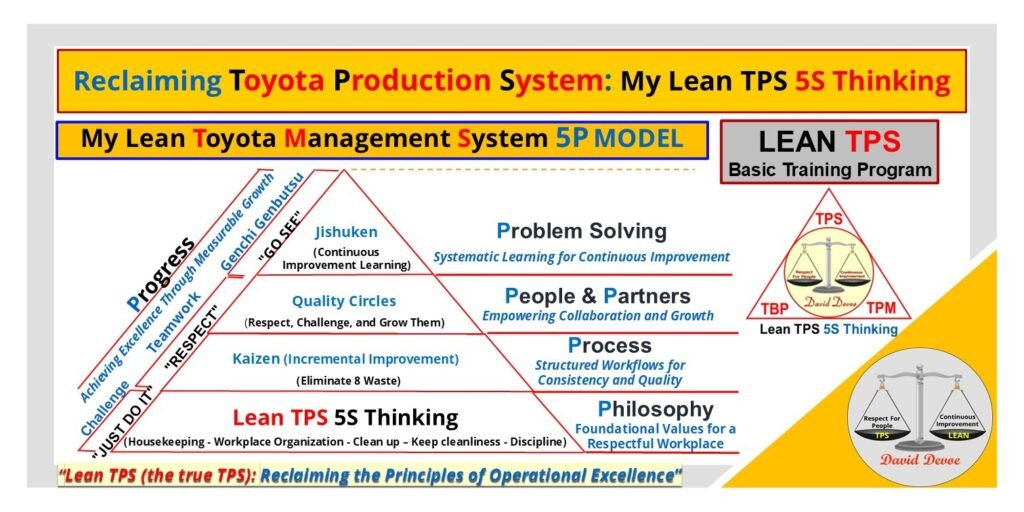

My Lean TPS 5S Thinking integrates directly with the Lean TPS 5P Model of Purpose, Process, People, Performance, and Perfection. Each S reinforces these five pillars. Sort and Set in Order connect to Purpose and Process by ensuring work aligns with value. Shine and Standardize build People and Performance by reinforcing consistency and visibility. Sustain drives Perfection by maintaining discipline and continuous reflection.

This integration transforms 5S from a cleaning activity into a learning system. It provides structure for how leaders train, evaluate, and improve their areas. Visual controls, standard locations, and consistent routines become signals of leadership engagement. Every improvement made under 5S strengthens the system for flow, safety, and quality.

The Connection to The Toyota Way 4P Model

The Toyota Way 4P Model of Philosophy, Process, People and Partners, and Problem Solving provides the cultural anchor that gives 5S its long-term purpose. My Lean TPS 5S Thinking applies these values in a structured, visual, and measurable way.

Philosophy defines why the work matters.

Process ensures consistent quality and flow.

People and Partners build capability through shared practice.

Problem Solving drives learning through observation and reflection.

5S Thinking is the visible expression of these values. It turns abstract principles into daily standards that can be seen, measured, and improved. Through 5S, Toyota transforms philosophy into tangible behavior at every workstation and in every office.

Learning through Practice: Kaizen and Jishuken

The strength of Lean TPS 5S Thinking is that it teaches through action. In every Kaizen and Jishuken activity, leaders and teams return to the fundamentals of 5S. Each improvement begins by checking the environment, how tools are placed, how flow is supported, and how standards are followed. This focus on structure makes every improvement measurable and repeatable.

Jishuken, meaning self-motivated study, connects leadership development directly to 5S. Leaders learn to see waste, analyze flow, and design countermeasures. The process builds confidence and capability. Through repetition, teams learn to maintain standards without supervision, creating a culture of accountability and mutual respect.

Why 5S Thinking Builds Operational Excellence

The visible outcome of 5S Thinking is a workplace that functions smoothly, safely, and efficiently. The deeper result is a culture of shared discipline. 5S Thinking eliminates waste, builds stability, and makes problems visible before they grow into failures. It reinforces the habits that drive Standardized Work, Kaizen, and Just In Time.

When 5S becomes a daily behavior, it transforms how people think and how work is performed. Every mark on the floor, every tool location, and every standard form becomes part of the organization’s nervous system, a visible expression of teamwork and respect.

The House of Toyota stands on this foundation. 5S Thinking is not the starting point of the journey; it is the structure that sustains it.