At Toyota L&F (Logistics and Forklifts), the largest facility of its kind operating under the Toyota Production System, I learned that 5S Thinking is far more than workplace organization. It is the foundation for Kaizen Thinking and the gateway to developing people who sustain improvement.

Toyota’s approach to Kaizen is often misunderstood outside Japan. In many North American organizations, Lean is introduced as a series of tools or events. At Toyota, Kaizen Thinking is a disciplined system of learning where improvement is structured, continuous, and directly linked to respect for people.

How 5S Thinking Builds Kaizen Thinking

The foundation of Kaizen is built upon 5S. At Toyota, 5S was not an isolated housekeeping initiative. It was the first structured step in developing a disciplined culture that could sustain improvement.

- Sort (Seiri) – Remove unnecessary items and make waste visible.

- Set in Order (Seiton) – Organize tools and materials to ensure efficient work flow.

- Shine (Seiso) – Maintain cleanliness and stability through inspection.

- Standardize (Seiketsu) – Establish visual controls and standard procedures.

- Sustain (Shitsuke) – Reinforce discipline so improvement becomes habit.

When applied as thinking, 5S creates stability, clarity, and structure. It enables people to see problems clearly, act on them immediately, and sustain gains over time.

At Toyota L&F, 5S Thinking ensured that improvement was not dependent on projects or audits. It became the way people worked every day.

The Link Between 5S Thinking and Kaizen

Kaizen cannot exist without 5S. Without structure, improvement efforts deteriorate into temporary fixes. 5S provides the discipline that allows Kaizen to function as a daily system rather than a special event.

At Toyota L&F, Quality Control Circles (QCC) operated as structured learning cycles. Teams met regularly to analyze performance, identify root causes, and implement improvements. Over time, these cycles developed Kaizen Thinkers who could sustain continuous improvement independently.

This process connected 5S to problem-solving, turning order and cleanliness into visible control and measurable performance.

From 5S to 2S: Nomura’s Deeper Lesson

Mr. Sadao Nomura, one of Toyota’s senior quality leaders, emphasized that the purpose of 5S is not appearance but function. His lesson was clear: “2S is not about tidiness. It is about eliminating waste at the root.”

Nomura’s Quality Kaizen method evolved from this understanding. He taught that the goal of 5S Thinking is to reach a level of maturity where only Standardize and Sustain remain—the true essence of continuous improvement.

At Toyota L&F, this evolution occurred naturally through disciplined practice:

- Early TPS adoption – 5S established the foundation for flow and stability.

- Kaizen development – Teams used 5S as the base for structured problem-solving.

- Kaizen maturity – 5S evolved into 2S, focusing on consistency and sustainment.

When this level is achieved, improvement becomes second nature. The system no longer depends on management instruction. It is sustained by the people who operate within it.

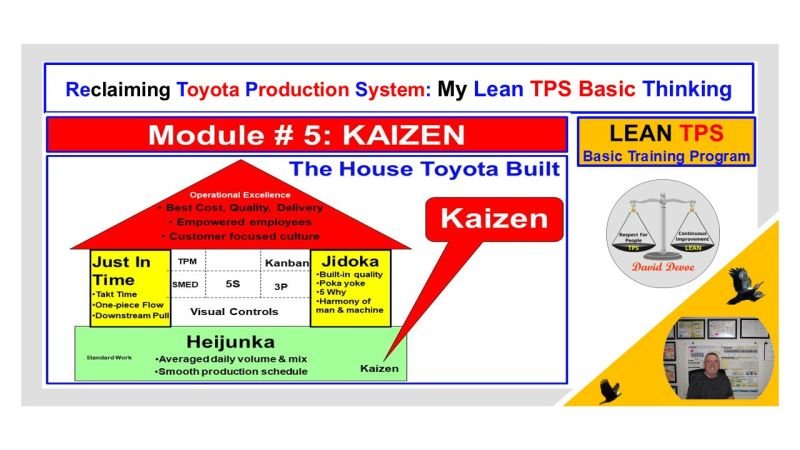

The Structure of the House Toyota Built

Toyota’s system can be visualized as a house. The foundation is Heijunka and Standardized Work, creating flow and balance. The two pillars are Just in Time and Jidoka, representing flow and built-in quality. At the center is 5S Thinking, the stability that supports every element of TPS.

At the top of the house is Kaizen, the continuous improvement that strengthens every part of the system. This structure represents the integration of philosophy, process, and people each reinforcing the other.

Kaizen as a System of Thinking

At Toyota, Kaizen is not an isolated activity. It is a learning process that improves both people and systems. When 5S Thinking matures, Kaizen Thinking follows naturally.

Without 5S, Kaizen lacks structure. Without Kaizen, 5S lacks purpose. Together, they form the core of Toyota’s culture of continuous improvement and respect for people.

Final Reflection

The House Toyota Built is not just a model. It is a mindset.

Once 5S Thinking is fully integrated, it evolves into 2S Thinking focused on standardization and sustainment. This maturity transforms improvement from a management directive into a daily habit.

This is how Toyota achieves long-term excellence through discipline, participation, and respect for people.