Most organizations begin their improvement journey with 5S. Yet many stop at surface-level cleaning, labeling, or audits. That is not how Toyota practiced it.

In Lean TPS, 5S is not a housekeeping activity. It is a system of disciplined thinking. It trains people to see clearly, think critically, and maintain readiness. It develops the ability to detect abnormalities and act before problems grow.

At Toyota, 5S was the foundation of Kaizen. It was the entry point for developing capability. Before people could improve flow, they had to learn how to create stability and recognize deviation. This was the purpose of 5S Thinking.

The Five S’s in Lean TPS

1. Sort (Seiri):

Remove what is not needed. The purpose is not organization for appearance but elimination of distraction and motion waste. Every unnecessary item hides flow problems and consumes space and attention. Red tagging was a form of problem identification, not housekeeping.

2. Set in Order (Seiton):

Design the workplace to support the correct work sequence. Every tool and material should have a defined location aligned with the standard method. Visual controls were never posters or slogans; they were signals that guided thinking and made abnormalities visible.

3. Shine (Seiso):

Cleaning is inspection. The act of cleaning is used to identify wear, leaks, and instability. Shine confirmed that equipment was ready, materials were safe, and the process could begin without interruption.

4. Standardize (Seiketsu):

Convert good practices into consistent systems. This includes visual layouts, color standards, and defined roles. Standardization ensures that everyone performs work the same way, reducing variation and confusion.

5. Sustain (Shitsuke):

Lead the behavior. Sustain is the leadership habit that turns standards into culture. It is not maintained through posters or slogans but through coaching and example. When leaders consistently reinforce discipline, 5S becomes part of daily work.

5S as Leadership Development

Inside Toyota, 5S was never delegated to junior staff. It was a leadership function. Team Leaders and Supervisors practiced 5S as part of their daily routine. They confirmed process stability, taught flow discipline, and reinforced accountability.

5S provided a structured way to observe, act, and learn. It revealed abnormalities before defects occurred. It also gave leaders a visible method to train their teams in judgment and ownership.

Why 5S Thinking Builds Capability

5S Thinking connects physical organization with mental clarity. It creates the environment where Kaizen, Standardized Work, and Just-In-Time can operate. It teaches people to manage their own workplace and think systematically about cause and effect.

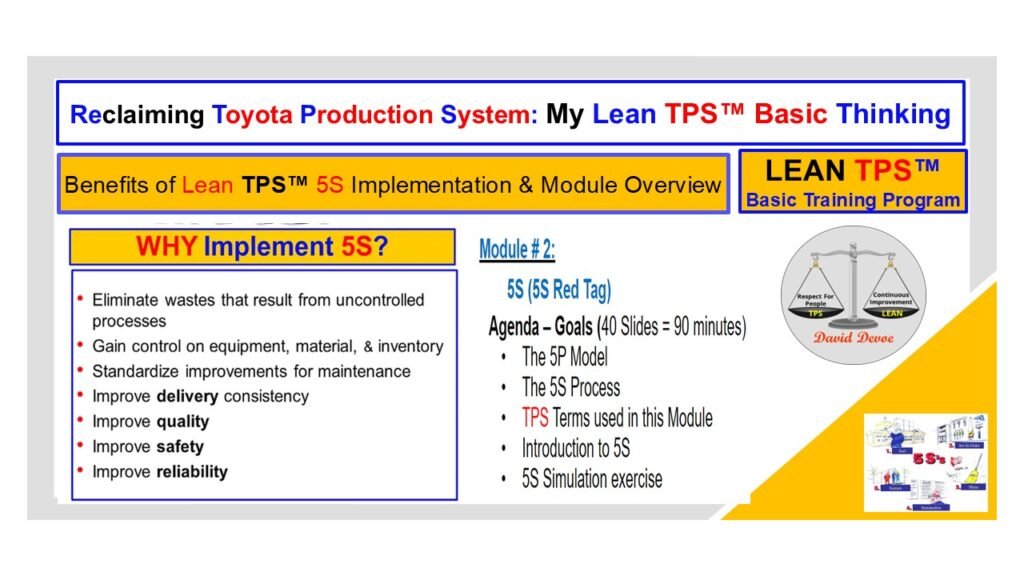

In Lean TPS Basic Training, we used 5S as the foundation for every learning module. It was not a one-time initiative but a repeating habit. The objective was always the same: to create a site that was safe, stable, and always ready for a customer visit.

Toyota’s approach to 5S can be summarized in four purposes:

- Correct problems in the moment

- Make standards visible to everyone

- Help teams learn by observing current conditions

- Build readiness for daily production and improvement

When practiced this way, 5S is not about scoring audits or cleaning schedules. It is about developing people who can sustain improvement and protect quality through structure and discipline.

The discipline of 5S Thinking transforms workplaces into learning systems. It is where Kaizen begins, and where the foundation for JIT, Jidoka, and Heijunka is built.