The Lean TPS 5P Model organizes the Toyota Production System into five interdependent elements: Purpose, Process, People, Performance, and Perfection. It links structure to philosophy, connecting what is done with why it is done. The model provides a clear framework for building capability, developing leadership, and sustaining improvement across every level of the organization.

Understanding the 5P Structure

Each element of the 5P Model represents a specific function of Lean TPS that reinforces the others. Together they form the management system that supports Toyota’s principles of continuous improvement and Respect for People.

Purpose defines direction and ensures that all work aligns with customer value and company objectives. Every activity begins with a clear understanding of why it matters. Purpose connects daily effort with long-term goals and guides decision making across all levels.

Process provides the structure that enables flow, stability, and quality. Standardized Work, visual control, and problem prevention are the methods that ensure consistency. Process improvement is never random. It is guided by data, confirmed by observation, and sustained through daily routines.

People are the center of Lean TPS. They create value through thinking and participation. The system depends on leadership that teaches, coaches, and supports rather than controls. Through Genchi Genbutsu, or “go and see,” leaders build understanding by observing reality directly. Respect for People means developing the ability of every individual to solve problems and improve their own work.

Performance measures progress and confirms reality. It provides visibility into how well the system is functioning. Metrics are not used for blame but to show where attention is needed. Safety, quality, delivery, cost, and morale are reviewed daily so that teams can learn and respond immediately.

Perfection represents the pursuit of continuous improvement through Kaizen and Jishuken. It is not an endpoint but a mindset that encourages reflection, learning, and disciplined action. Perfection is achieved not by adding new tools but by improving the fundamentals until stability becomes culture.

The Link Between 5P and The Toyota Way 4P Model

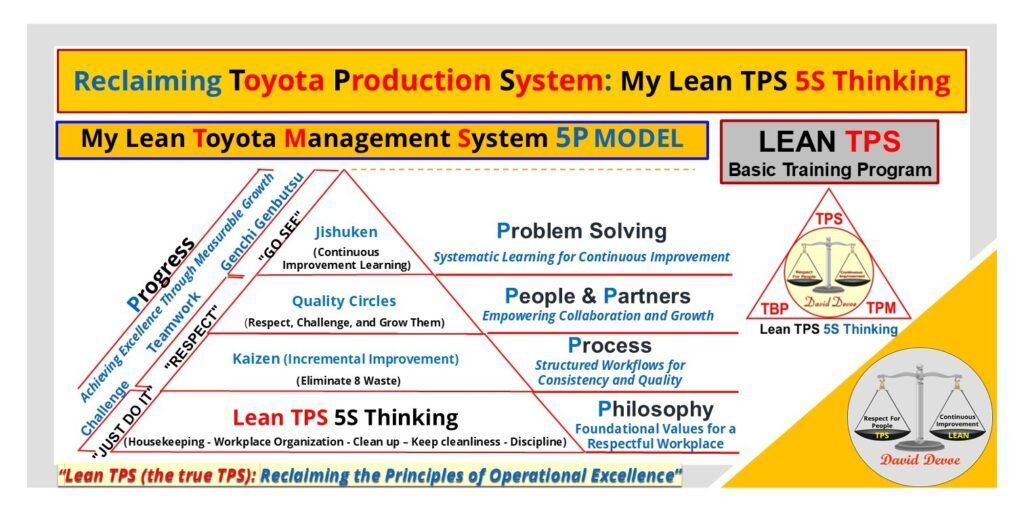

Jeffrey Liker’s Toyota Way 4P Model provides the philosophical base that gives the 5P structure its depth. The four elements of the Toyota Way—Philosophy, Process, People and Partners, and Problem Solving—mirror and support the Lean TPS 5P framework.

Philosophy defines long-term purpose and establishes decisions that benefit both company and society. Process ensures quality by design, not by inspection. People and Partners strengthen teamwork and mutual respect. Problem Solving ensures continuous learning by addressing root causes.

The 5P Model transforms these principles into a daily operating system. It translates the abstract values of the Toyota Way into visible actions that can be practiced, measured, and improved. The two models work together: the 4P Model explains the mindset, and the 5P Model provides the method.

How 5S Thinking Supports the 5P Model

5S Thinking is the foundation that makes the 5P Model visible and sustainable. Without the structure and discipline created by 5S, the 5P Model cannot function effectively. Sort and Set in Order align with Purpose and Process by clarifying value and removing waste. Shine and Standardize build People and Performance through routine practice and shared standards. Sustain drives Perfection by reinforcing habit, ownership, and reflection.

This alignment shows that 5S and 5P are not separate initiatives but part of one system. 5S builds the environment where the 5P Model can operate. The 5P Model, in turn, ensures that the structure created by 5S continues to evolve through improvement and leadership involvement.

The Role of Leadership in Applying the 5P Model

Leadership is the key to making the 5P Model work. At Toyota, leaders are not removed from the work; they participate directly in improvement. They use the 5P Model as both a teaching tool and a reflection method. Each “P” becomes a lens for evaluating how well the system is performing and where coaching is required.

When leaders clarify Purpose, they align teams. When they strengthen Process, they create stability. When they develop People, they build problem-solving ability. When they review Performance, they promote accountability. When they pursue Perfection, they sustain improvement as a way of life.

The effectiveness of the 5P Model depends on this leadership behavior. It is not an audit checklist. It is a management habit that reinforces the connection between people, process, and purpose.

Why the 5P Model Reclaims the True Meaning of Lean

In many organizations, Lean has become a project or a cost-cutting program. The 5P Model reclaims Lean as it was intended in the Toyota Production System. It reminds leaders that the purpose of Lean TPS is not to eliminate people but to eliminate waste. The focus is on building capability and improving systems, not reducing headcount.

By aligning Purpose, Process, People, Performance, and Perfection, the 5P Model restores Lean TPS as a system for sustainable growth. It teaches that improvement must be structured, measured, and supported by leadership. It transforms Lean from a collection of tools into a living system that connects thinking, action, and results.

When practiced with discipline, the 5P Model becomes a learning framework for the entire organization. It helps teams understand the logic behind their actions, leaders understand the purpose behind their direction, and the company align improvement with long-term value.