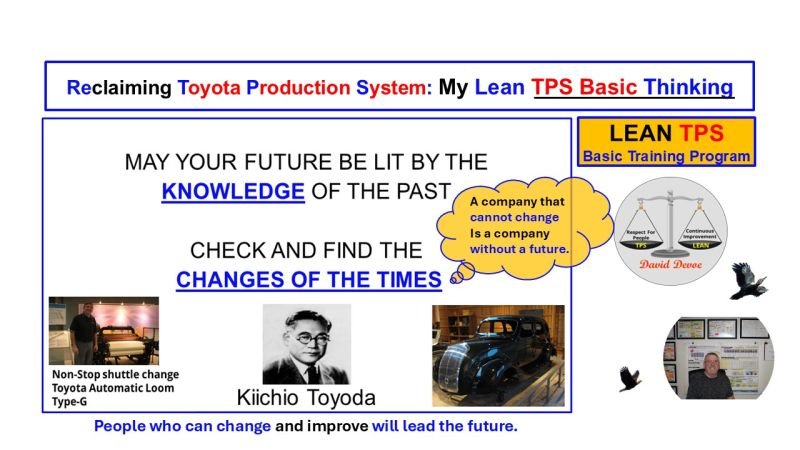

Reclaiming Toyota Production System: My Lean TPS Basic Thinking

Change is not achieved through slogans or one-time projects. It requires leadership, participation, and accountability. Within the Toyota Production System, change is sustained through structure. Leaders act, employees participate, and processes evolve through continuous learning.

Lean TPS defines change as a disciplined cycle of observation, reflection, and action. It connects leadership behavior, employee involvement, and system design into a process that continually improves. The following principles outline how organizational change is led through Lean TPS.

1. Leadership and Accountability Drive Change

Leadership within TPS begins with presence and follow-through. It is not about authority but about responsibility for results. Too often, initiatives start with enthusiasm but lose momentum when leaders fail to reinforce expectations at the Gemba.

Lean TPS leaders do not delegate accountability. They engage directly, confirm progress, and provide coaching. Every improvement must have a responsible owner, a clear standard, and a method for verification. Sustainable change occurs when leadership reviews results regularly and adjusts based on evidence.

2. Employee Involvement Builds Ownership

People support what they help create. Mandates often fail because employees do not understand their role in the process. Lean TPS ensures engagement through the Plan-Do-Check-Act cycle.

- Plan: Define the problem and involve the team in setting measurable objectives.

- Do: Test changes through controlled trials.

- Check: Review outcomes using data, not opinion.

- Act: Standardize successful practices and train others.

When teams are involved in designing solutions, they take ownership of outcomes. In Toyota, this participation is considered an investment in capability development, not a cost of time.

3. Communication Must Be Clear and Timely

A common cause of failure in change initiatives is poor communication. When information flows only through limited channels or key details are delayed, alignment breaks down.

Lean TPS builds communication into the process. Visual boards, A3 reports, and daily meetings make progress visible and remove dependence on a single individual. Information is shared through standard formats that everyone can access and understand. This transparency allows faster decisions and consistent alignment.

4. Recognizing and Retaining Talent Drives Change

Continuous improvement depends on people who think critically and act responsibly. Many organizations lose their most capable employees by overlooking their contributions while hiring external talent at higher cost.

Toyota’s philosophy is to develop people before results. Recognition is not only financial; it is trust, opportunity, and challenge. Employees who are recognized for problem-solving and leadership are more likely to sustain improvement. Retention becomes a reflection of culture, not compensation.

5. Competitive Readiness Requires Continuous Improvement

Markets, technologies, and customer expectations evolve. The organizations that survive are those that improve faster than their environment changes.

Lean TPS builds adaptability through continuous observation and reflection. Leaders conduct regular reviews of performance and lessons learned. Problems are viewed as opportunities for study, not failure. This mindset ensures that every issue contributes to future capability.

A company that cannot change is a company without a future. The organizations that learn continuously maintain competitiveness without relying on external intervention.

6. Follow-Through Turns Strategy into Results

Planning is only the beginning. Without follow-up, strategy becomes wishful thinking. Toyota teaches that every policy or initiative must have a feedback mechanism. Actions must be confirmed, verified, and reflected upon.

Follow-through ensures that improvement is more than activity. It transforms ideas into measurable outcomes. Leaders who follow up demonstrate respect for people because they show that every effort matters and every problem deserves resolution.

7. A Culture of Kaizen and Jishuken Keeps Change Moving

Change is sustained through habits of reflection and learning. Kaizen teaches teams to identify and solve problems daily. Jishuken teaches leaders to study processes directly, understand variation, and lead improvement through participation.

A Kaizen culture encourages everyone to think about how work can be made safer, faster, and more stable. A Jishuken culture develops leaders who see problems early, confirm facts, and coach others in structured problem-solving. Together they form the living foundation of organizational adaptability.

Final Thought

Successful change is not managed. It is mastered through practice, persistence, and leadership that engages people. Lean TPS provides the structure and discipline to ensure improvement becomes part of daily work rather than a short-term program.

Organizations that align leadership, employee engagement, and structured follow-up create stability and trust. They move beyond reaction to proactive development, turning continuous improvement into a permanent capability.