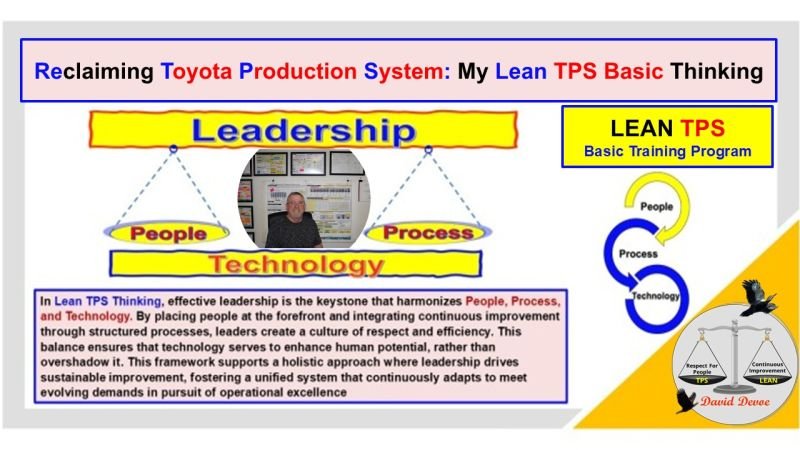

Sustainable improvement cannot be achieved through tools or technology alone. Within Lean TPS, leadership is the keystone that connects People, Process, and Technology. When these three elements are harmonized, improvement becomes both sustainable and adaptable. When they are not, systems become fragmented, results are short-lived, and technology often overshadows human capability.

Leadership within Toyota Production System thinking begins with Respect for People. This principle ensures that improvement starts where value is created, with the people who do the work. Leaders are responsible for developing the environment, structure, and habits that allow people to think, solve problems, and continuously improve. Without leadership discipline, no process or technology can sustain results.

People First

In Lean TPS, people are the foundation of performance. Leadership focuses on engagement, problem-solving, and skill development. Every person in the organization must understand how their work contributes to flow, quality, and safety. Leaders create systems that make problems visible and support those who solve them. The ability to build trust and capability is what defines leadership strength.

Structured Process

Structured process connects people and purpose. Standardized Work provides the foundation for consistent performance and learning. It establishes the baseline for improvement and ensures stability in daily operations. Leadership ensures that these processes are followed, reviewed, and refined through continuous improvement. Without process discipline, variability increases and waste spreads.

Technology as a Support, Not a Substitute

Technology must enhance, not replace, human thinking. In Lean TPS, automation is designed to support efficiency and safety, not to eliminate human responsibility. Jidoka, or built-in quality, ensures that technology works alongside people to detect and correct problems early. Leaders must balance the integration of technology with the development of people to maintain flexibility and resilience.

The Leadership Balance

The role of leadership is to sustain harmony between these three elements. When leadership focuses only on technology, people disengage. When it focuses only on process, improvement becomes rigid. When it focuses only on people without structure, results lack consistency. Effective Lean TPS leadership balances all three to maintain stability while driving continuous progress.

This balance creates a culture of respect, learning, and accountability. It transforms technology into a tool that supports human capability and ensures that processes continuously evolve to meet changing needs. Leadership provides the alignment that connects purpose to performance.

Final Thought

Leadership is the integrating force within Lean TPS. It connects the discipline of process, the strength of people, and the potential of technology. When these three elements work together, improvement becomes a natural part of daily work. True operational excellence is achieved when leadership maintains this balance, ensuring that progress remains grounded in respect, structure, and adaptability.