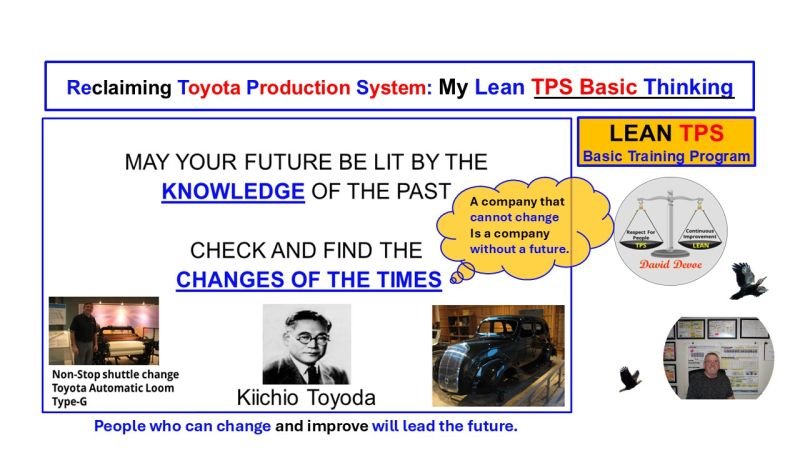

Reclaiming Toyota Production System: My Lean TPS Basic Thinking

Change defines leadership. It determines whether an organization learns, adapts, and grows or remains static and vulnerable. Within the Toyota Production System, change is not a project or an event. It is a continuous process guided by leadership discipline, team participation, and structured problem-solving.

Toyota teaches that the ability to change is the ability to survive. Leaders must see change not as disruption but as learning. The true role of a Lean TPS leader is to make improvement part of daily work, connecting reflection, accountability, and adaptability.

People Can Change, but Not Everyone Will

One of the first lessons in leadership is that while people can change, not all will. The difference lies in mindset. Leaders who believe people cannot change stop investing in development. They focus on control instead of growth. Those who believe in change create conditions that make learning possible. They coach, observe, and guide their teams through uncertainty. In Lean TPS, this belief is reinforced through the principle of Respect for People. The purpose of leadership is not to demand performance but to build capability.

The Scale of Change Leadership

Most managers underestimate how much of their work involves change. Studies and real-world experience show that roughly 80 percent of a leader’s time is spent influencing, aligning, and adjusting systems. Every new standard, meeting format, or workflow improvement represents change. What separates strong leaders from weak ones is awareness. In Toyota, even small leadership adjustments can have a multiplier effect on performance. When a leader consistently applies daily management, communication, and coaching habits, improvement compounds across the organization. Change is not limited to processes. It includes behaviors, expectations, and decision-making. Leaders who approach every change with structure and intent help stabilize operations and develop confidence in their teams.

Why Many Leaders Struggle with Change

Despite its importance, few leaders receive practical training in leading change. Many assume that issuing instructions or introducing new tools will create compliance. In practice, forced change produces short-term compliance and long-term resistance. Lean TPS provides the structure that converts change from reaction to discipline. The PDCA cycle ensures change is tested before implementation. The A3 process provides a visual logic that clarifies problems, causes, and countermeasures. The principle of Genchi Genbutsu ensures decisions are based on facts observed at the Gemba, not assumptions. When leaders skip these steps, they create confusion. Rushed decisions and unclear expectations lead to frustration. Sustainable change depends on understanding cause and effect before action is taken.

Leadership Creates the Environment for Change

The best leaders create an environment where people feel safe to challenge current conditions. Leadership is not about control but about guidance. In Lean TPS, leaders who drive successful change share common practices. They build trust by listening before acting. They involve employees in shaping change rather than announcing it. They coach teams on problem-solving methods instead of providing answers. They recognize that resistance is natural and support people through transition. They verify outcomes and remain engaged after implementation. Leadership in TPS means being visible, accessible, and accountable. The leader’s presence communicates importance. Their follow-up communicates respect.

Change as a Measure of Competitiveness

Organizations that adapt outperform those that maintain comfort. Competitive readiness depends on continuous improvement and reflection. In Toyota’s history, every major advancement, from the automatic loom to the production system, resulted from leaders responding to changing conditions with creativity and discipline. A company that cannot change is a company without a future. This belief, expressed by Kiichiro Toyoda, remains central to Toyota’s philosophy. Change capability determines both survival and long-term success. Leaders who practice Lean TPS thinking anticipate change before it is forced upon them. They study variation, design countermeasures, and build systems that absorb new challenges without breaking stability.

Developing the Capability to Lead Change

Lean TPS embeds leadership development within the improvement process. Every PDCA cycle builds the skill to observe, decide, and act based on evidence. Each A3 report reinforces cause-and-effect thinking. Over time, these routines form the discipline required to lead larger transformations. Leaders who develop these capabilities early gain adaptability that extends throughout their careers. They can face new technology, market shifts, and organizational challenges without losing clarity. This is the deeper purpose of Lean TPS Basic Training, to prepare leaders who can guide others through continuous change.

Final Thought

Change leadership is not theoretical. It is practiced every day through decisions, standards, and reflection. Lean TPS provides the structure to manage it. The system connects leadership, people, and process so that change becomes a natural part of work, not a disruption. Organizations that master change through Lean TPS do not wait for crisis to act. They anticipate, adapt, and improve continually. Leaders who develop this mindset ensure their teams remain capable, competitive, and aligned with the times.