The foundation of Toyota’s 5S Thinking began long before the term “Lean” was ever used. In the early 20th century, Henry Ford’s CANDO system Clean, Arrange, Neatness, Discipline, and Ongoing improvement set the stage for modern production methods. Ford understood that order and discipline were not management slogans but prerequisites for quality and flow.

Toyota engineers studying Ford’s approach in the 1930s took those ideas and restructured them into a system that could be taught, practiced, and sustained. What began as CANDO evolved into Toyota’s 5S Thinking: Sort (Seiri), Set in Order (Seiton), Shine (Seiso), Standardize (Seiketsu), and Sustain (Shitsuke). Each step became more than a housekeeping activity. It became a disciplined method to reveal waste, expose problems, and stabilize work.

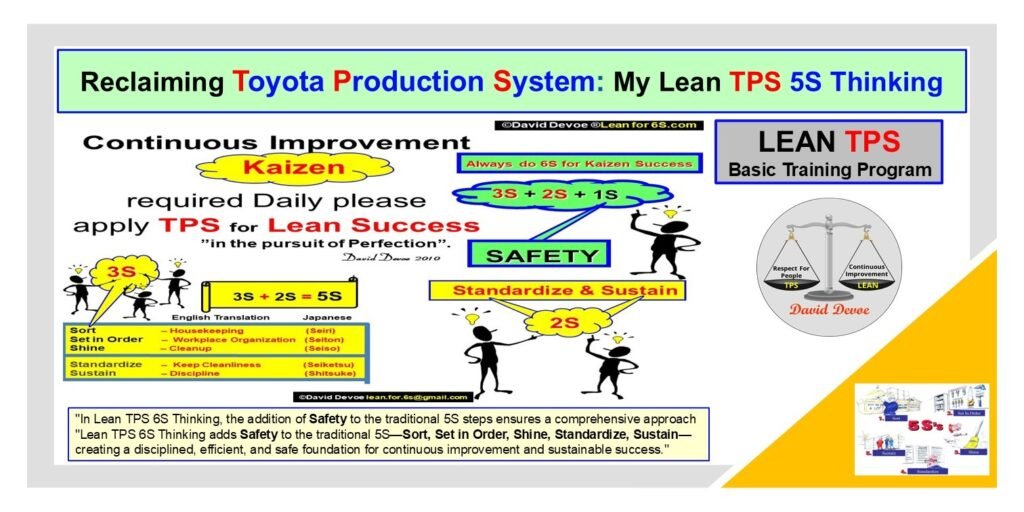

The first three S’s Sort, Set in Order, and Shine address physical order and cleanliness. They make abnormality visible and build pride in the workplace. The last two S’s Standardize and Sustain create consistency and discipline. Together they transform daily work into a learning system where structure supports continuous improvement.

Over time, Toyota expanded this system by introducing a sixth S: Safety. Safety was not an addition for compliance. It represented the company’s Respect for People philosophy. True safety in Lean TPS is built through design and structure. A clean, organized, and standardized environment naturally prevents accidents and creates stability for workers. The formula 3S + 2S + 1S = 6S became a simple way to communicate this balance between efficiency, discipline, and care.

In Lean TPS 6S Thinking, safety and improvement are inseparable. A workplace that is unsafe cannot be efficient. A process that is disorganized cannot be improved. 5S Thinking builds the structure; Safety ensures that structure protects people. Together, they create the conditions for Kaizen to thrive.

At Toyota, Kaizen was never a separate event. It was a daily discipline built on the foundation of 5S and Safety. Each improvement began by seeing what was abnormal, questioning why, and taking action to correct it. 5S Thinking made the workplace a classroom. Kaizen made it a laboratory for learning.

Ford’s CANDO system gave industry the first model of structured improvement. Toyota’s 5S Thinking transformed that model into a culture of continuous learning. Lean TPS 6S Thinking carries that legacy forward. It is how organizations sustain quality, efficiency, and safety through structure and discipline.

In Lean TPS, every improvement begins with a clean, organized, and safe workplace. It is the physical expression of Respect for People and the first real step toward continuous improvement.