Kaizen and the Toyota Production System

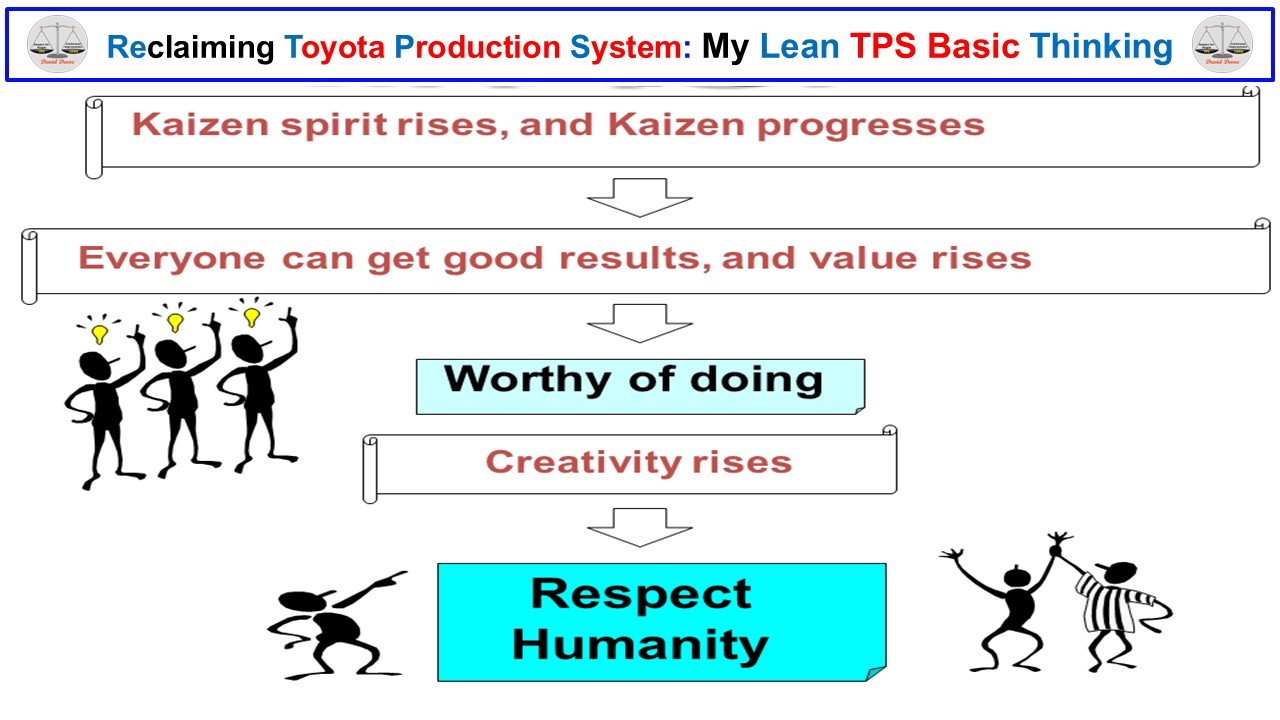

Kaizen in Lean TPS is a core principle of the Toyota Production System. It means change for the better, but within TPS it is a methodical approach to learning and improvement. Every individual is expected to participate in identifying problems, proposing ideas, and taking corrective action. This approach builds a culture where improvement is not an event but a daily behavior grounded in responsibility and ownership.

Kaizen is effective because it connects people directly to their processes. Through direct participation and practical problem solving, employees learn to improve efficiency, quality, safety, and productivity. Small, continuous adjustments accumulate into major gains over time. This incremental approach reflects the heart of TPS thinking.

Key Goals of Kaizen

Kaizen focuses on several core objectives that strengthen both systems and people:

Incremental Improvement

Frequent small changes create system stability and prevent major disruptions. The goal is steady progress, not large projects.

Quality at the Source

Each improvement aims to strengthen quality and prevent defects from moving downstream.

Waste Elimination

Kaizen relies on identifying and removing non value added activity across processes. Reducing waste improves flow, safety, and reliability.

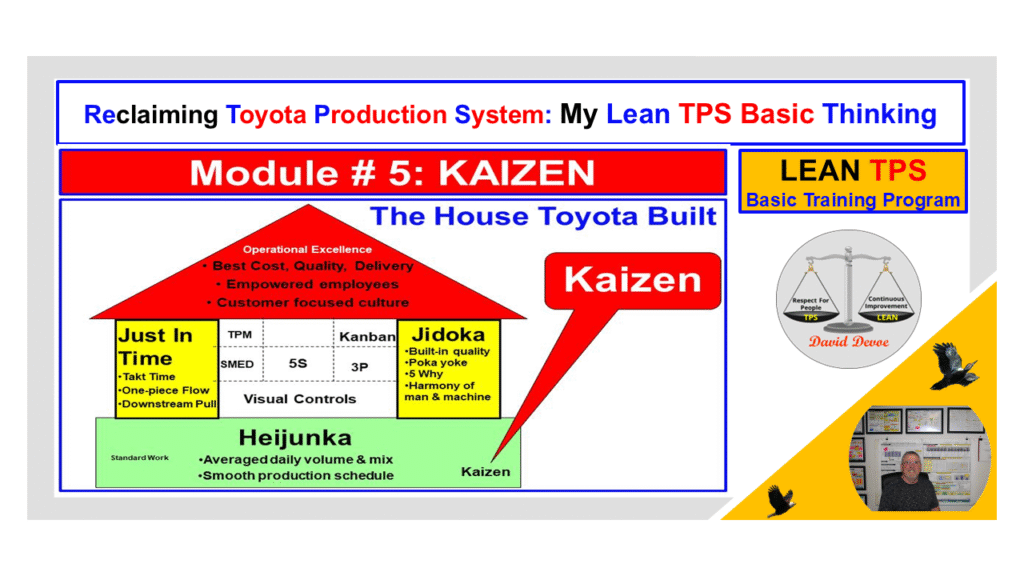

The House Toyota Built – TPS Framework

The Toyota Production System integrates Kaizen through its major pillars. These elements create the structure that supports continuous improvement.

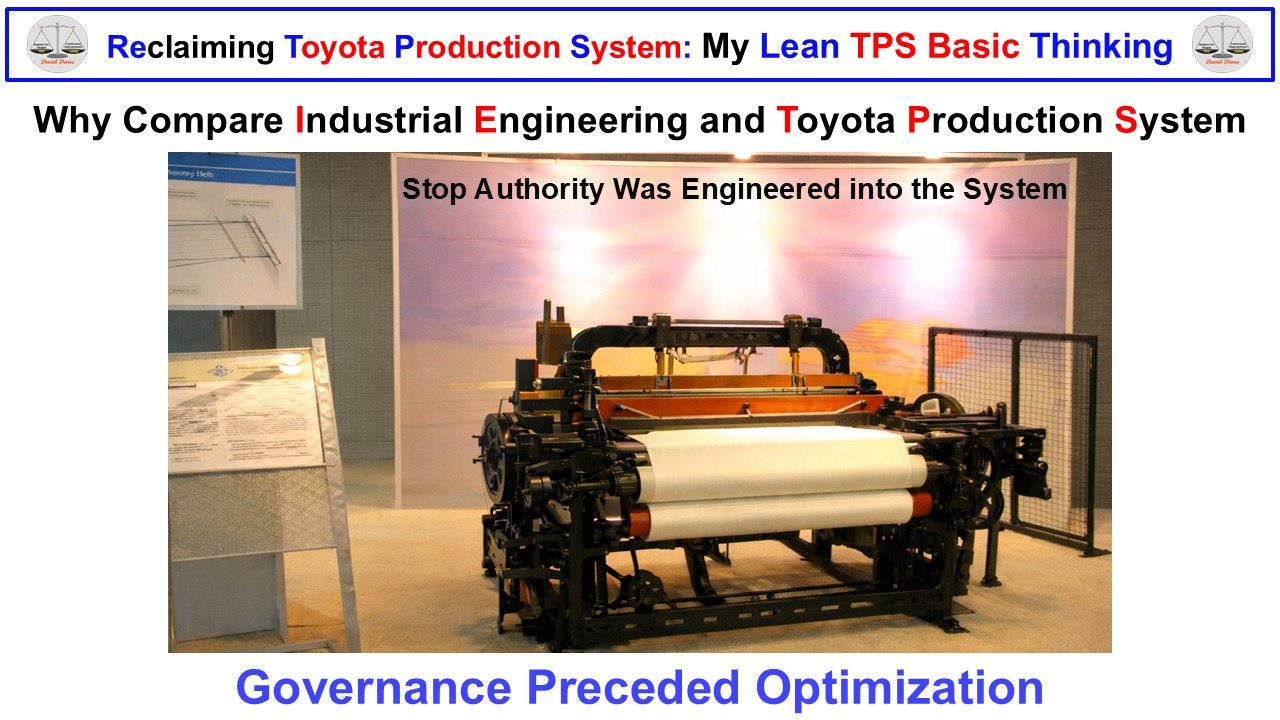

Jidoka

Automation with a human touch that stops the process when abnormalities occur. Jidoka includes mistake proofing, 5 Why root cause analysis, and visual confirmation of stability.

Just in Time

Producing only what is needed by synchronizing work with demand. Takt time, one piece flow, and downstream pull are central concepts that reduce inventory, delay, and variability.

Heijunka

Leveling production by managing volume and mix. Heijunka reduces unevenness and overburden, improving system stability and throughput.

5S and Visual Controls

Strong workplace organization makes abnormalities visible and strengthens confirmation. 5S supports flow, exposes problems early, and builds discipline into daily behavior.

These components work together to create a system where improvement is expected and supported.

Key Elements of Kaizen Activities

Kaizen supports improvement across both processes and equipment. The goal is to achieve flow while maintaining safety, quality, and efficiency.

Process Improvements

Teams improve workflow by removing redundancy, clarifying sequence, reducing motion, and stabilizing operation.

Equipment Improvements

Machines and tools are adjusted after process improvements are confirmed. This ensures reliable performance and supports stable flow.

Core Principles for Improvement

Kaizen uses four core principles to redesign processes with clarity:

Elimination

Remove activities that do not add value.

Combination

Combine actions when possible to reduce unnecessary steps.

Rearrangement

Adjust the order or layout of work to improve flow.

Simplification

Make work easier, safer, and more efficient by reducing complexity.

These principles guide structured improvement and support long-term system stability.

Applying Kaizen in Daily Work

TPS emphasizes direct observation. Kaizen begins with Genchi Genbutsu: go and see. Teams study the work at the place where value is created. They confirm facts, identify abnormalities, and understand causes.

Kaizen also relies on root cause analysis through 5 Why. This structured thinking helps teams move beyond symptoms and solve the source of the problem.

Daily Kaizen builds a disciplined rhythm of looking for issues, addressing them quickly, and checking results. It develops confidence and capability at every level of the organization.

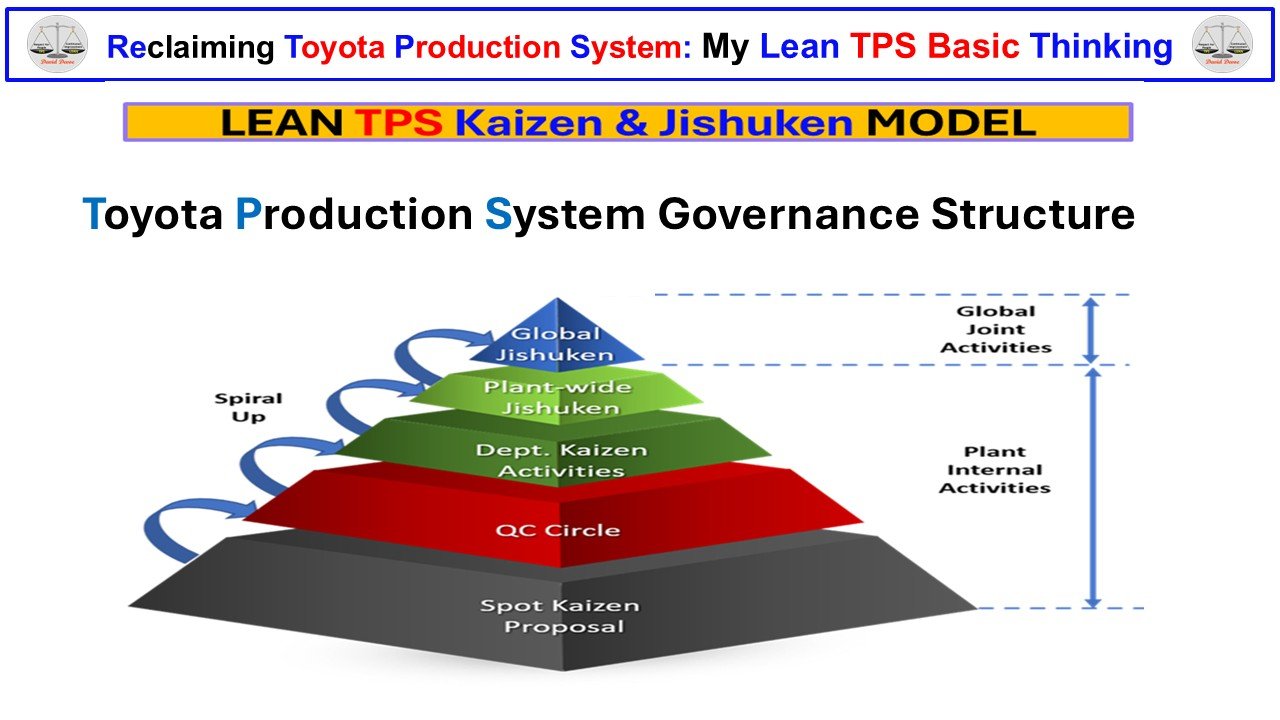

Jishuken – Self Directed Improvement

Jishuken is a deeper form of Kaizen. It is self directed improvement led by operations and leadership teams working together. Jishuken focuses on strengthening capability, improving processes, and developing leadership behaviors.

Teams conduct structured analysis, confirm facts at the Gemba, and implement system level improvements. Jishuken connects daily Kaizen to long term capability development across the organization.

Kaizen Events and Cross Functional Improvement

Kaizen Events are focused, short duration improvement activities. They rely on a clear project charter that defines purpose, scope, objectives, financial impact, and team members. During the event, teams study the process, identify waste, improve flow, and confirm the results.

Kaizen Events are most effective when supported by daily Kaizen habits and strong Standardized Work. They convert learning into practical improvements and allow teams to build capability in a structured environment.

Supporting Systems – TPM and SMED

Kaizen is reinforced by TPS support systems.

Total Productive Maintenance

TPM reduces equipment related losses and builds shared responsibility for reliability.

Quick Changeover (SMED)

Quick changeover reduces downtime by separating internal and external work. This increases flexibility and responsiveness while reducing waste and defects.

These systems strengthen flow and support the continuous improvement culture.

Conclusion

Kaizen is the foundation of continuous improvement in Lean TPS. It builds capability, teaches people to see waste, strengthens flow, and develops a culture of responsibility. When organizations practice Kaizen with structure and purpose, they gain stability and create long term operational excellence.

If your organization is ready to begin its Lean TPS journey, starting with Kaizen will build the habits, discipline, and clarity required for sustainable improvement.