The Toyota Production System is a system for learning. Every element of TPS is designed to develop people through structure and practice. Lean TPS Basic Training is not about tools or awareness sessions. It begins with participation, simulation, and teaching. The way we learn defines how we lead.

How We Learn in Lean TPS

The Lean TPS learning funnel shows that reading and listening provide the lowest retention. Reading gives us about ten percent. Hearing words adds a little more, reaching twenty percent. Viewing pictures and charts helps understanding reach thirty percent.

Real learning begins at the next levels. Teaching others increases retention to seventy percent because it forces clarity and reflection. Simulation and practice reach ninety percent as people test countermeasures and see cause and effect. The highest level, one hundred percent, is participation. This is Jishuken, where leaders and teams take responsibility for studying their own processes, analyzing data, and applying countermeasures.

Jishuken: Leadership Learning in Motion

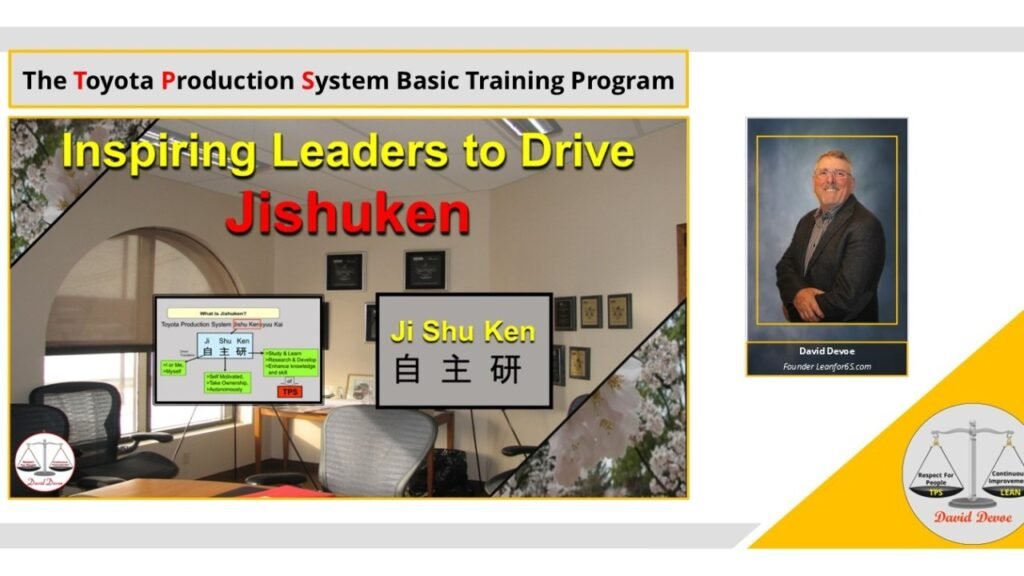

Jishuken (自主研) translates to self-motivated study. It is composed of three ideas: Ji (self), Shu (mastery), and Ken (study). These define Toyota’s belief that learning and improvement are personal responsibilities carried out together.

A Jishuken is not a classroom or event. It is leadership in action. Managers and supervisors work with their teams to study the real conditions of work. They identify waste, unevenness, and overburden, then develop countermeasures together. Through this process, leaders build understanding by seeing for themselves.

Leadership development happens at the Gemba, not in offices. Leaders learn by doing. They confirm facts, observe the work, and connect cause and effect. This is how Toyota develops capability and respect at the same time.

Structure + Action = Capability

The foundation of Lean TPS learning is structure. Reading and hearing build awareness. Visuals create shared understanding. Teaching and simulation transform awareness into ability. Participation transforms ability into capability.

This sequence produces a simple formula: Structure + Action = Capability. Without structure, learning is scattered. Without action, it fades. When both are combined, people grow stronger through experience.

The Jishuken Method

A Jishuken follows a disciplined structure similar to PDCA.

- Clarify the Objective. Define the theme using measurable goals in quality, cost, or delivery.

- Observe the Current Condition. Go to the Gemba and record facts, not opinions.

- Analyze the Cause. Apply the 5 Whys to identify root causes and confirm them with data.

- Develop Countermeasures. Create and test ideas with team participation.

- Implement and Verify. Confirm the effect of the countermeasure in real time.

- Reflect and Standardize. Capture learning through A3 reports and update Standardized Work.

Each Jishuken produces two outcomes: a better process and more capable people. The process improvement can be measured. The human development sustains the system.

Leadership at the Gemba

Genchi Genbutsu means go and see for yourself. Jishuken is the structure that makes this a leadership habit. Problems are not solved from reports. They are solved at the workplace.

During a Jishuken, leaders observe work cycles, confirm motion patterns, and study Standardized Work Charts. They do not rely on summaries or second-hand explanations. They stand with the operators to understand the facts. Leadership shifts from directing to developing.

This is the essence of Toyota leadership. A leader’s job is not to demand results but to build the ability to achieve them.

From Japan to North America

Jishuken was developed under Taiichi Ohno in the 1970s as a supplier improvement method. Over time, Toyota expanded it inside its own operations as a leadership development tool.

When Toyota Industries Corporation extended Jishuken to North America, it emphasized coaching over compliance. Under the guidance of Mr. Susumu “Sonny” Toyoda, the approach focused on teamwork, respect, and reflection. This created an environment where learning and improvement advanced together.

Teaching as Learning

Teaching is a powerful way to learn. In Lean TPS, leaders who teach others must understand deeply. Demonstrating Standardized Work or guiding 5 Whys problem solving reinforces mastery and discipline. Every time a leader teaches, the system strengthens.

Simulation and Practice

Kaizen simulations provide a safe way to test new ideas. They turn theory into experience. Teams learn how layout changes, motion design, and flow adjustments affect performance. These exercises build confidence and prepare people for real improvement activity at the Gemba.

Participation: The Highest Level of Learning

Participation completes the cycle. In a Jishuken, everyone studies, acts, and reflects together. Leaders and operators share responsibility for results. Participation transforms knowledge into skill and skill into habit.

When participation becomes part of daily work, improvement becomes culture. Problems are no longer hidden. They are studied openly and solved collectively.

Building Capability through Learning by Doing

The purpose of Lean TPS Basic Training is to build capability. Awareness alone cannot sustain improvement. Capability grows when structure and action are combined. Each step of the training builds on the one before it:

5S creates order.

Kaizen develops teamwork.

Standardized Work defines rhythm.

Jishuken builds leadership.

This sequence develops thinking people who can identify and solve problems systematically.

Conclusion

The Toyota Production System is more than a manufacturing method. It is a learning system that develops people. Jishuken represents its highest form because it unites leadership, participation, and structured problem solving.

When organizations learn through action, improvement becomes continuous. When leaders teach and participate, respect for people becomes visible. The formula remains constant across every level of TPS: Structure + Action = Capability.